Do you have a question about the Wilo EMU FA Series and is the answer not in the manual?

Specifies requirements for personnel working with the product, emphasizing qualified personnel for specific tasks.

General overview of safety instructions and technical information provided in the manual.

Outlines essential safety precautions for installation, operation, and maintenance of the product.

Specific safety instructions for electrical work, emphasizing qualified personnel and adherence to regulations.

Guidelines for electrical connections, including precautions against dampness and electromagnetic radiation.

Considerations for different pumped fluids and warnings about handling explosive liquids.

Importance of regular maintenance by qualified personnel and proper logging of work performed.

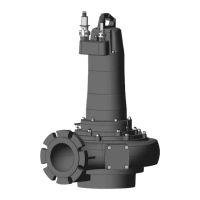

Describes the primary applications and intended uses of submersible motor pumps.

Specifies permissible fluid properties like density and viscosity for pump operation.

Lists and explains the function of safety and monitoring devices integrated into the machine.

Presents specific technical parameters of the machine, including operational and dimensional data.

Details key operational parameters such as flow rate, head, speed, and voltage.

Provides essential data related to the motor, including current, power, and operating modes.

Information on connecting the power supply, including cable specifications and connectors.

Instructions for inspecting delivered items for damage and completeness upon arrival.

Guidelines for safe transportation, requiring appropriate equipment and qualified personnel.

Recommendations for storing the product, including temperature control and protection from environmental factors.

Key points to observe during installation to prevent damage or serious injury.

Details various vertical and horizontal installation methods available for the machine.

Step-by-step guide for performing wet installation using a suspension unit.

Explanation of the dry installation method, including collector tank and machine room setup.

Instructions for portable installation using a pump pedestal, covering securing and operation.

Information on ensuring adequate water levels and implementing dry-run protection systems.

Pre-startup checks required, including installation type, operating mode, and water coverage.

Guidelines for laying electrical lines, connecting the motor, and ensuring correct direction of rotation.

Overview of motor protection requirements and different activation methods for motors.

Critical items to monitor after startup to ensure proper operation and performance.

Specifies the recommended intervals for performing various maintenance checks and tasks.

Provides a detailed overview of lubricants used, their specifications, and manufacturers.

Step-by-step procedure for draining and refilling lubricants in the machine's chambers.

Instructions for draining and refilling the coolant, including specific fluid recommendations.

General guidelines and important information applicable to all repair work on the machine.

Tables providing correct torque specifications for tightening various types of screws.

Procedure for temporary shutdown, ensuring the machine remains submerged.

Steps for final shutdown, disconnection from power, and preparation for storage.

Actions and checks required before restarting the machine after a prolonged storage period.

Lists common causes and remedies for the machine failing to initiate operation.

Addresses issues where the motor protection trips shortly after the machine begins running.

Diagnoses and resolves problems where the machine operates but does not move fluid.

Identifies reasons and solutions for the machine performing below specified operating levels.

Provides troubleshooting steps for machines exhibiting erratic or noisy operation.

Solves issues related to shaft seal leaks and faults reported by the sealing chamber monitor.

Guidance on contacting customer service if initial troubleshooting steps do not resolve the issue.

A log for recording all maintenance and alteration work performed on the machine.

Explains the meaning of labels used on screw plugs for maintenance purposes.

Describes the components and intended function of anchor bolts for securing foundations.

Specifies the approved applications and material requirements for anchor bolts.

Provides dimensions, drill hole specifications, and tightening torque values for anchor bolts.

Guidance on choosing compatible motors and frequency converters for optimal operation.

Recommends temperature sensors and approved motor protection relays, especially for Ex motors.

Conditions under which motors can be operated at frequencies up to 60 Hz.

Presents technical specifications of the Ceram CO coating, including density and resistance.

Details the resistance ratings of the coating against various pumped fluids and temperatures.

Emphasizes the importance of proper surface preparation for achieving optimal coating results.

Provides step-by-step instructions for repairing damaged coating areas.

Key steps for safely unloading large units, with emphasis on load safety and proper handling.

Critical safety precautions for electrical connection, requiring authorized electricians.

Details monitoring devices, their identification, recommended devices, and triggered conditions.

Lists wire designations, their corresponding colors, and functions for electrical connections.

Lists the applicable EC directives that the product complies with for market access.

Lists the harmonized standards that have been applied to the product.

| Seal | Mechanical seal |

|---|---|

| Protection Class | IP68 |

| Solids handling | Yes |

| Voltage | 230 V, 400 V |

| Frequency | 50 Hz |

| Pump Material | Cast iron |

| Impeller Material | Cast iron, stainless steel |

| Temperature Range | Up to 40°C |

| Operating mode | Continuous |

| Series | EMU FA Series |