Maintenance

E:\shares\Baprod\BA\subtec_m\sewage\us\fkt27\maintenance.fm 7-3

Maintenance intervals

Overview of the maintenance intervals needed:

Before initial start-up or after

a longer period of storage

- Checking the insulation resistance

- Fill level check in cooling system - fill level must be between the minimum and the maximum

marks on the cooling jacket

- Fill level check in sealing chamber – lubricant must reach up to the lower edge of the filling

opening

Monthly

- Monitoring the current consumption and voltage

- Checking the used relays for posistors, sealing room monitor, etc.

Every six months

- Visual inspection of the power supply cable

- Visual inspection of the cable holder and the cable bracing

- Visual inspection of accessories, e.g. the suspension device and hoisting gears

8,000 operating hours or after

two years

- Checking the insulation resistance

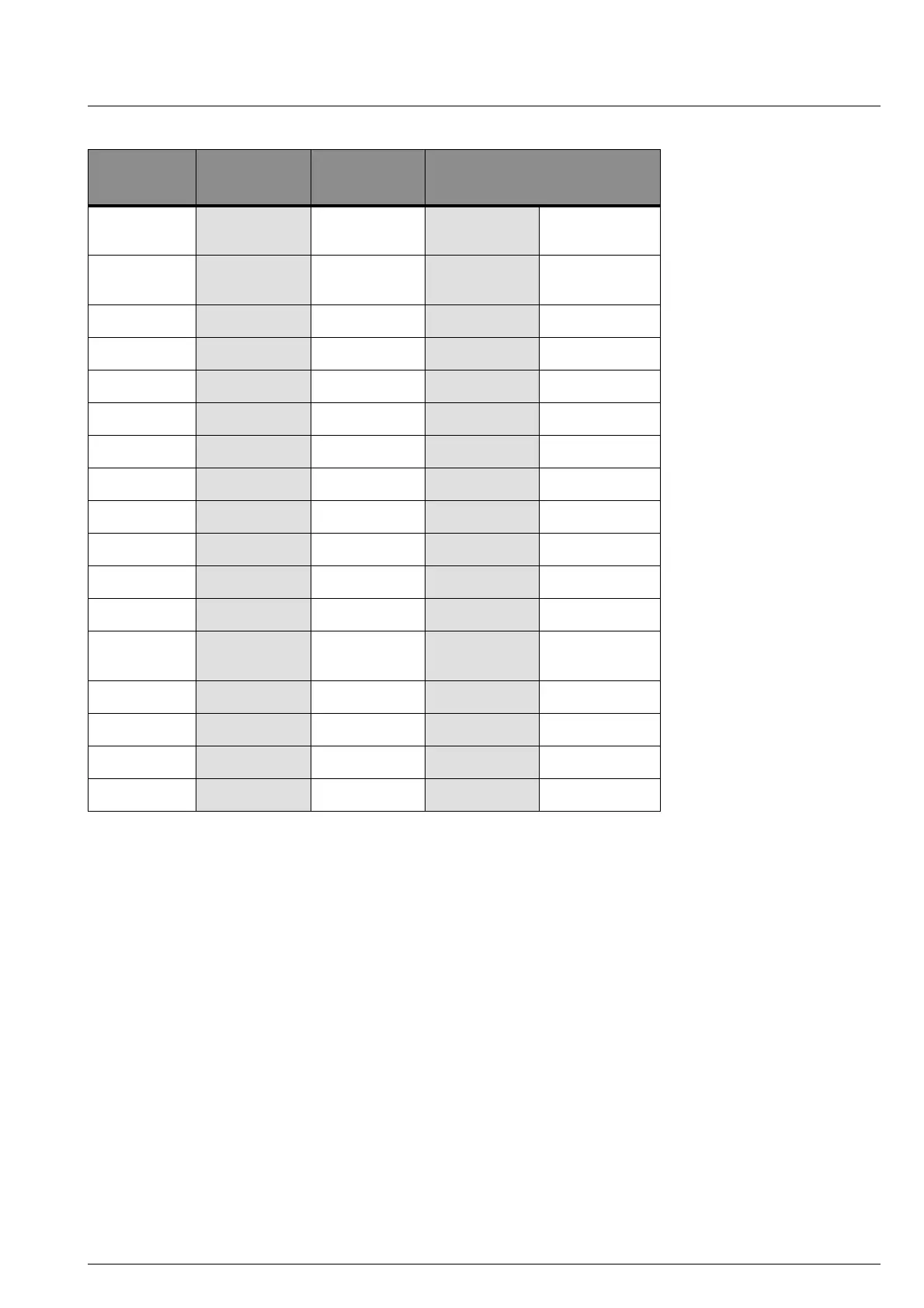

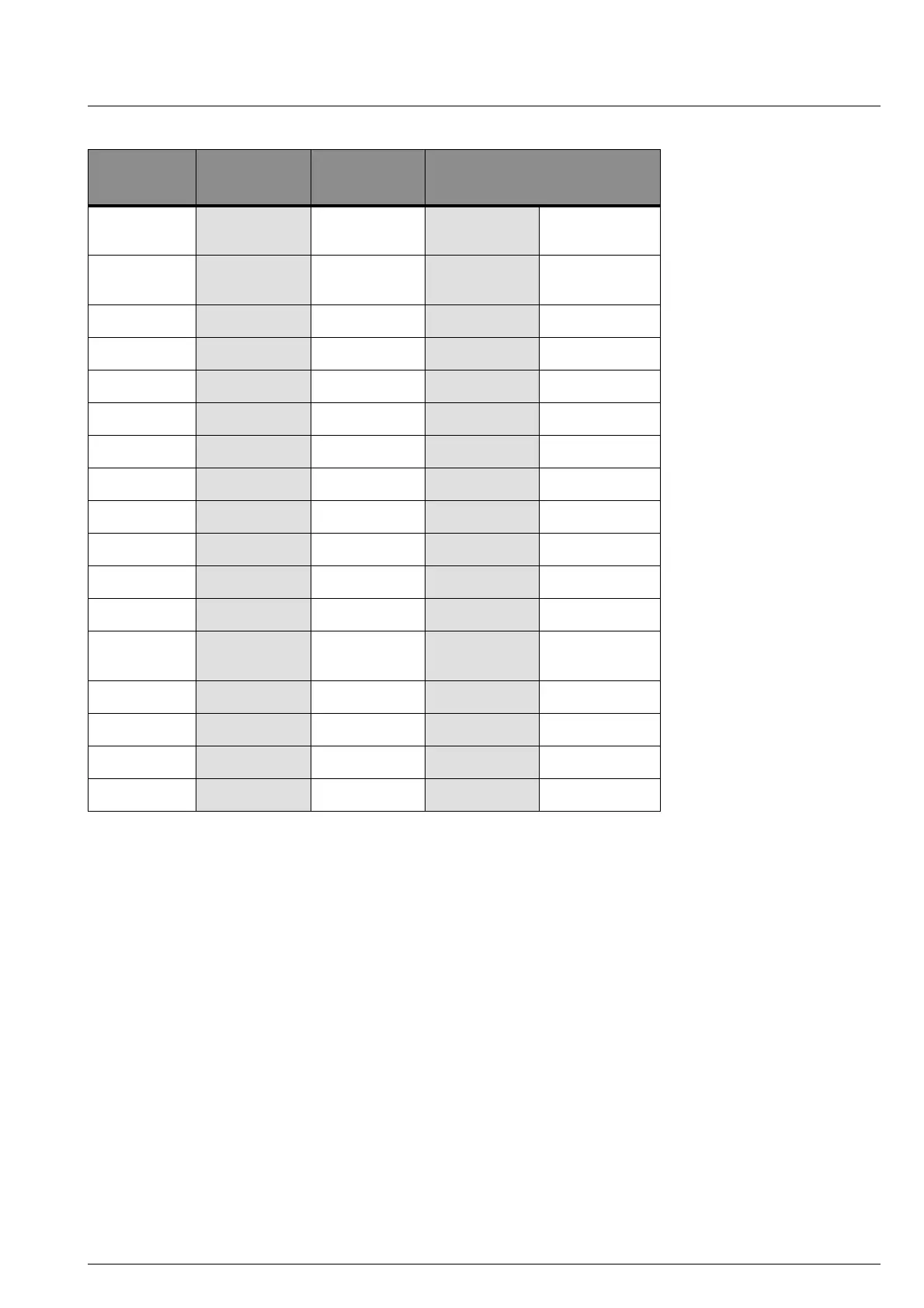

Company BP

LEU Energie

GmbH & Co. KG

Prokühlsol

GmbH

Fauth & Co. KG

Basis

Monopropylene

glycol

Propane-1,2-

diol

Propane-1,2-

diol

Propane-1,2-diol

Color None None Light yellow None

Purity 80% - 94.99% 96% - 98%

Density 1.056 g/ml 1.051 g/ml 1.050 g/cm

3

1.051 g/ml

Boiling point 140 °C 164 °C 185 °C 188 °C

pH value 7.9 9.9 7.5 - 9.5 -

Water 3% - 9.99% Max. 5%. - 0,20%

Nitrite None None None None

Amine - None None None

Phosphate - None None None

Silicate - None None None

Water hazard

class

1 1 1 1

FDA approval - Yes - -

HT1 approval - Yes - -

Afssa approval - Yes - -

Remarks - - - For medical use

Status

Production

stopped

Product used Possible alternatives

Table 7-2: Technical Data – Glycol Overview

Loading...

Loading...