ENGLISH

7

free SPDT (single pole, double throw) contacts, max. switch rating

250 V – 1 A, DC power output 24 V.

Sensor P:

Terminals for wiring connections to pressure or float switch respec-

tively for On/Off pump control.

TLS:

Terminals for wiring to low water cut-out or overflow alarm respec-

tively. The differing possibilities of dry-run protection and their res-

pective wiring are depicted in Fig. 3.

WSK:

Terminals for wiring to motor integrated overload protection devices

WSK (thermal winding contacts) or PTC-sensors. Hook switches

and potentiometers located on the unit board must be set for the

different unit functions. These are described in Chart 1.

6 Commissioning

All functional adjustments on the ER1(-A) control unit as laid out in

Chart II must have been set prior to initially starting-up of the connec-

ted pump plant.

7 Maintenance

The control unit is maintenance-free.

8 Faults - Causes and Remedies

Blinking green light:

Motor overload cut-out has responded.

No automatic reset after rectification of fault cause.

To reset: Switch selector switch to “0”

Red light On:

Switch-off due to low-water or overflow respectively.

Automatic reset after rectification of fault cause.

Reset is also possible by switching the selector switch to “0”.

SSM:

On each fault event and overflow alarm.

If the fault cannot be remedied please contact your Installer or

your nearest WILO service.

Technical modifications reserved!

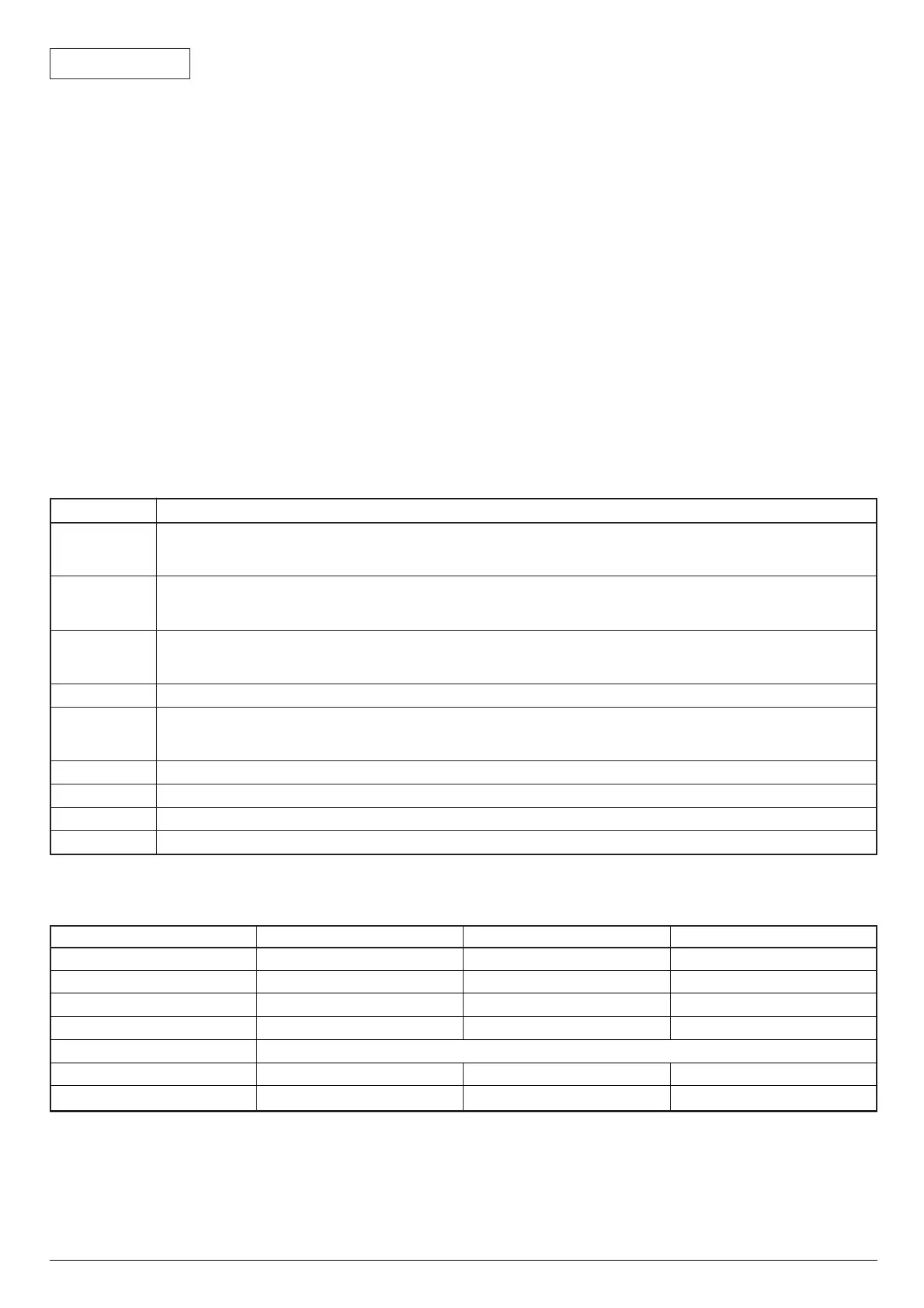

Chart 2: Settings of hook switches and potentiometers for different applications

Switch/Pot. Pressure boosting Fire services Waste disposal**

S 2 *0* *1* 0

S 3001

S 4001

S 6 top top bottom

6P1 (R 10) see motor name plate

6P2 (R 27) 2 2 0

6P3 (R 48) 0.5 0.5 0

** 0

→ Hook switch open, 1 → Hook switch closed

** Factory settings

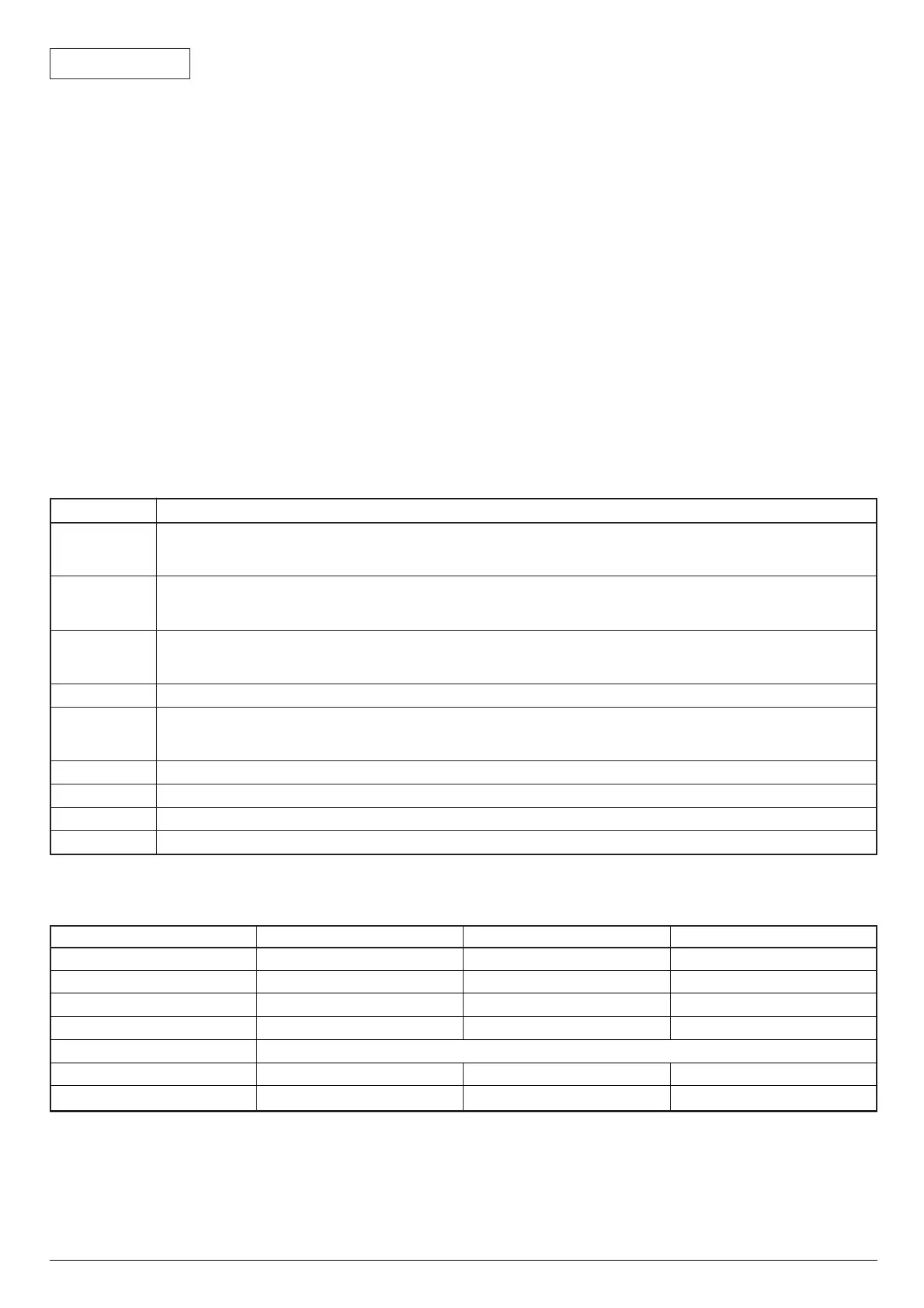

Chart 1: Functions of hook switches and potentiometer (Fig. 2)

Switch/Pot. Functions

S 2 Effect reversal for sensor input:

S 2 open: Pump runs on closed sensor contacts

S 2 closed: Pump runs on open sensor contacts

S 3 Test run:

S 3 open: Test run activated

S 3 closed: Test run deactivated

S 4 Effect reversal for TLS input:

S 4 open: Pump stops on low water (pressure boosting)

S 4 closed: Pump starts on overflow (submersible pump)

S 5 Switch is not active with standard design

S 6 Effect reversal for the TLS input

S 6 top closed: Pump stops on low water

S 6 bottom closed: Pump starts on overflow

S 7 Switch for function extension Output option

P 1 Setting to suit motor full load current

P 2 Time delay after pump stop command (0 - 2 min)

P 3 Time delay for stop on low water / start on overflow

Loading...

Loading...