33

English

WILO SE

10 Faults, Causes and Remedies

WARNING! Risk of electric shock!

Danger from electrical current must be eliminated.

Before carrying out any electrical work, the pump and accessory must be

de-energised and protected against unauthorised restarting.

WARNING! Risk of scalding!

If the water temperature and system pressure are high, close the gate valves

upstream and downstream from the pump. As a first step, allow the pump to cool

down.

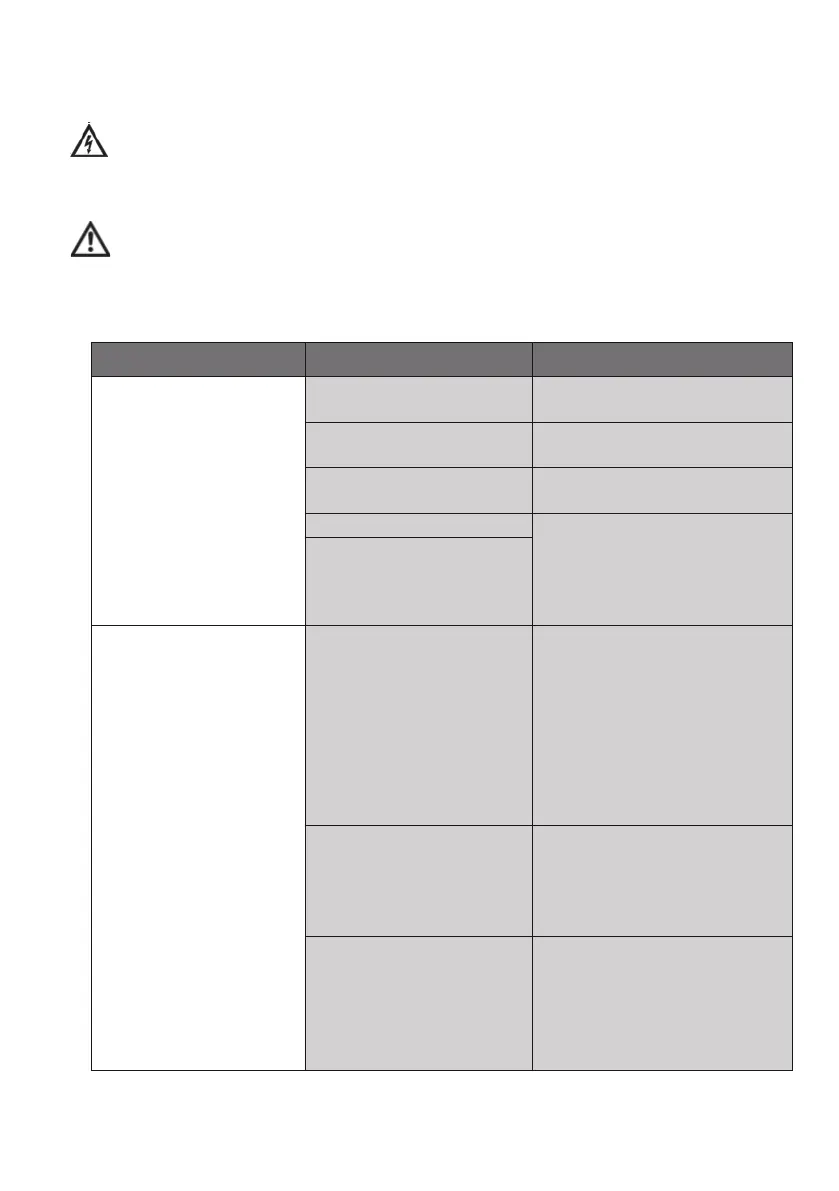

Faults Causes Remedies

The pump will not stop Loss of water of more than

3 l/min on the pipework

Service the system, taps, toilets, etc.

Printed circuit board fault Printed circuit board fault:

replace the PCB

Incorrect electrical connection Check the connections against the

diagrams in Fig. 5 and 6

Pump incorrectly adjusted Adjust the duty point of the pump so

that it is not operating too close to

the reset and stop conditions set by

the automatic control system,

i.e. 1.5 bar and 95 l/h

The control system is not

suitable for this type of pump

The pump will not start The pump was not primed with

water

The protection against dry running

has been triggered in and the FAILURE

LED has lit up: prime the pipe by

emptying the water from the system

and turning on a tap at the level of

the HiControl 1 to reduce the pres-

sure in the water column beneath,

and check by pressing manually the

RESET button.

Insufficient water The safety system has been activated

ans the FAILURE indicator light has

turned on. Check the power supply

and start the pump using the manual

RESET button

Pump blocked FAILURE indicator light on. Thesafety

system was activated. When the

RESET button is pressed, the ON

indicator light turns on, but the pump

doesn't start. Contact technical

support

Loading...

Loading...