ENGLISH

9

1 General Information

Installation and commissioning only by qualified personnel

1

.1 Uses

The pump is suitable for hot and cold water and other fluids free from

mineral oil and without abrasives or long-fibred substances. The main

areas of use are in water supply installations, as a booster pump, as a

boiler feeder pump, in industrial circulation systems, in process tech-

nology, in cooling water systems, in fire extinguishers and in washing

and sprinkler installations.

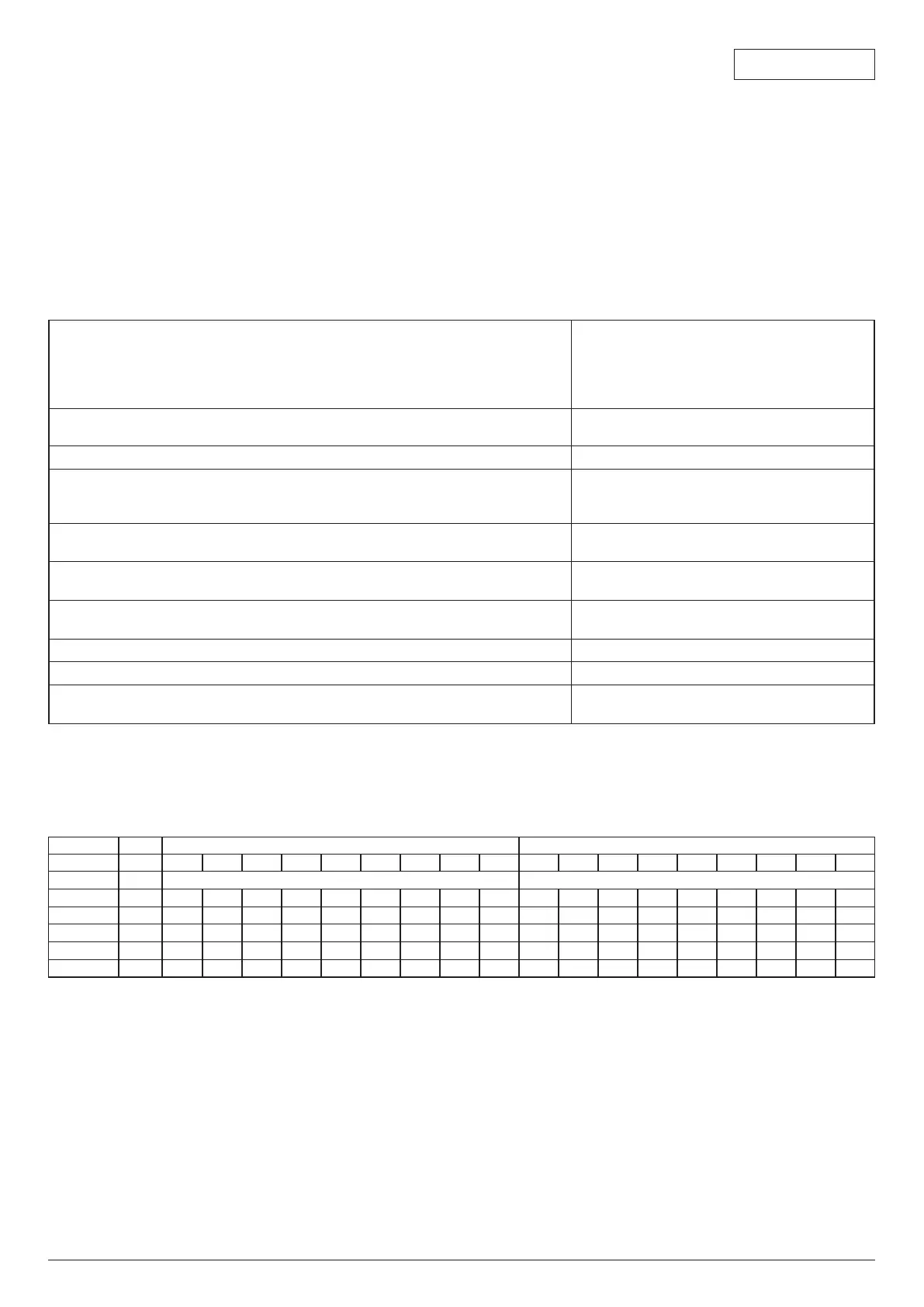

1.2 Product data

1.2.1 Connection and electrical data (Table 1)

Pumping medium allowed

Permissible media temperature

Maximum ambient temperature

Maximum permissible working pressure: at the inlet (inlet pressure see paragraph 5.3)

at the outlet, for a 2 pole motor

at the outlet, for a 2 pole motor

Mains voltages DM: for P

2

≤ 4 kW:

for P

2

≥ 5.5 kW:

Standard motor for P

2

≤ 5.5 kW:

for P

2

≥ 7.5 kW:

Speed 2 pole version

4 pole version

Mains fuse protection

Insulation class

System of protection

Drinking water in acc. with Drinking Water Order

Heating water / service water

Condensate

Water/glycol mixture

1

)

Other liquid media

2

)

-15

°C to +120 °C

(Follow catalogue instructions)

+40 °C

16/10 bar

16/25 bar

16/16 bar

3 ~ 230/400 V ±

10 %, 50 Hz

3 ~ 400 V ± 10 %, 50 Hz

V 18 standard motor

V 1 standard motor

2900 RPM

1450 RPM

see motor rating plate

F

IP 55

better protective systems available

1

) When using a water-glycol mixture containing up to 40 % glycol (or media with a viscosity different to that of pure water, the flow data for the pump must be adjusted accord-

ing to the higher viscosity of the flow media, regardless of the percentage of the viscous matter. Only use branded goods with corrosion protection-inhibitors, follow manufac-

turer’s instructions.

2

) If other and also aggressive chemical fluids are to be pumped, be sure to follow catalogue instructions and first obtain the approval of WILO.

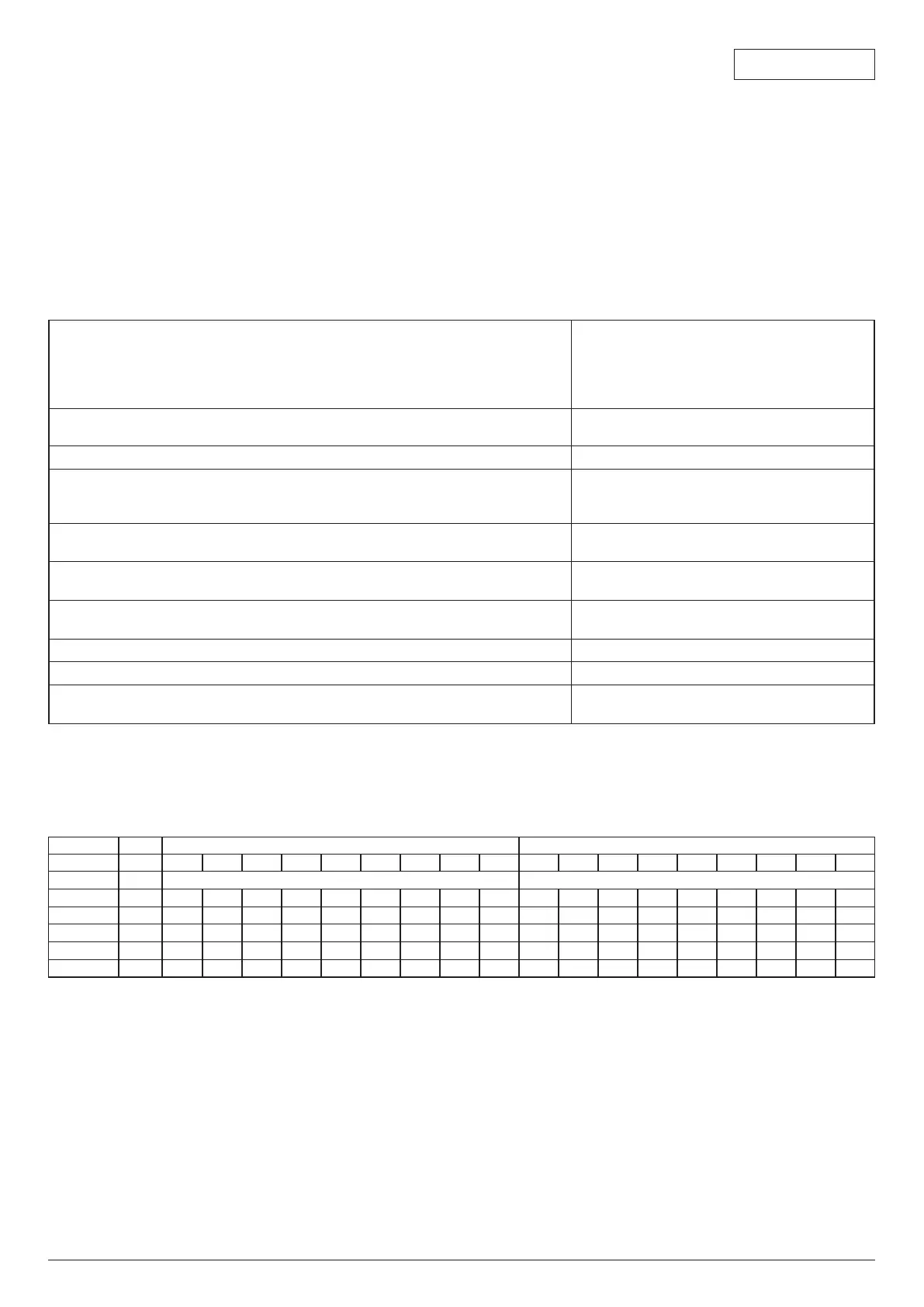

Principal dimensions and connection dimensions (Table 2, see also Fig. 3):

When ordering spare parts, please give all the information on the pump/motor rating plate.

Types PN16 version PN25 version

A B Y W Z E F J K A B Y W Z E F J K

MVI mm mm

1602 è 1614 DN50 194

252 20 215 130 300 90 125 4x18 194 252 20 215 130 300 90 125 4x18

3202 è 3216 DN65 235

235 35 195 195 320 105 145 4x18 260 260 35 220 220 320 120 145 8x18

5202 è 5212 DN80 260

260 30 220 220 320 105 160 8x18 260 260 30 220 220 320 105 160 8x18

7001 è 7007 DN100 261

350 45 280 199 380 140 180 8x19 261 350 45 280 199 380 140 190 8x23

9501 è 9506 DN100 261

350 45 280 199 380 140 180 8x19 261 350 45 280 199 380 140 190 8x23

Loading...

Loading...