WIL-IO-SP-WCC17001-11

5

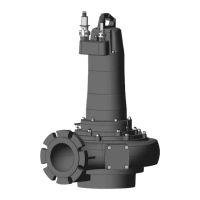

Picture 1

8. OPERATION

Do not handle this pump or plug in or unplug this pump with wet hands or while standing in water, unless

you are certain all power has been turned off to the pump. Remember, the pump should be connected only

to a properly grounded, GFCI outlet.

1. Make certain the pump is submerged in water. Running the pump dry can damage the shaft seal.

2. Insert the float switch piggy-back plug into a properly 115V GFCI grounded power outlet and the pump plug into

the piggyback plug. The pump will start operating when the float switch moves up over the pump top. The water

will be pumped out. When the water lowers to certain level, the float switch will turn off the pump.

3. The motor is equipped with an automatically resetting thermal overload protector. If the motor gets too hot, the

overload protector will shut off the pump before it is damaged. When the motor has cooled sufficiently, the

overload protector will reset, and the motor will restart.

NOTICE: If the overload protector stops the pump repeatedly, disconnect the power from the pump and check to

find the problem. Low voltage, a long extension cord, clogged impeller, or water that is too hot can cause motor

overheating.

9. MAINTENANCE

• Periodically unplug the pump, making certain your hands are dry, and you are not standing in water. When the

power is disconnected, inspect the pump inlets and remove all debris, then plug pump back into the grounded (GFCI)

outlet.

• To clear a pump clogged with debris, first, UNPLUG PUMP from electrical power. Then referring to Picture 2 below,

unscrew the stainless screws #1, then the volute #5, and the seal gasket #4. Use a flathead screwdriver to hold the

shaft #2 then turn the impeller #3 counter-clockwise to release the impeller. Remove debris from around the shaft

and on and under the impeller. Then reassemble the impeller, gasket, volute, See Picture 2.

Check valve

Loading...

Loading...