English

10 Wilo AG 05/2006

6 Description and operation

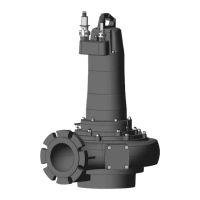

6.1 Pump description (Figure 1)

The submersible motor pump is driven by an

enclosed motor that is impermeable to presswa-

ter. Motor and pump have a continuous shaft. The

flow medium enters from below through the cen-

tral suction opening and exits by the vertical pres-

sure-pipe connection. The pump has a built-in

non return valve (pos. 5).

The TS 40 pumps are delivered with a half-open

impeller (pos. 23). It pumps solids up to 10 mm Ø

(no fibrous materials such as grass, leaves or rags).

For stationary installation, the pump is screwed to

a fixed pressure-pipe (R 1½), and for transporta-

ble installation to a hose connection.

The motor of both types is sealed with a mechan-

ical tandem seal (pos. 20) on the medium and

motor side against the pump housing. So that the

seals are lubricated and cooled in the case of dry

running, the chamber between the mechanical

seals is filled with oil.

CAUTION! Risk of leak!

If the mechanical seal is damaged, small quanti-

ties of oil may leak into the flow medium.

The motors are fitted with a thermal motor pro-

tection (1

~

: thermal winding contact (WSK), 3

~

:

thermal motor control) that automatically

switches the motor of if there is a threat of it over-

heating and switches it back on again once it has

cooled down. A capacitor is fitted at the 1

~

motor

to generate the rotary field.

7 Installation and electrical connection

Installation and electrical connection should be

carried out in accordance with local regulations

and only by qualified personnel!

WARNING! Risk of personal injury!

The relevant accident precaution regulations

must be observed.

WARNING! Risk of electric shock!

Potential dangers caused by electrical energy

must be excluded.

Local or general regulations [e.g. IEC, VDE, etc.]

and directives from local energy supply compa-

nies are to be followed.

7.1 Installation

The pump is designed for stationary and trans-

portable wet-well installation.

CAUTION! Risk of damage to the pump!

• Only suspend the pump using a chain or rope

from the transport loop, never by the electric

cable or pipe / hose connection.

• When the pump is lowered into the shaft or pit

the connecting cable must not be damaged.

• The pump must be installed in a frost-free place.

•

The shaft must be free from coarse solids (e.g.

building rubble) prior to installation and commis-

sioning.

• See catalogue for installation dimensions.

• The pressure-pipe must show the pump’s nominal

width (R 1½, possibility for expansion).

7.1.1 Stationary wet-well installation

In the case of stationary wet-well installation of

TS 40 pumps with pressure-pipe the pump is to be

positioned and secured such that:

• the pressure-pipe connections do not bear the

weight of the pump,

• the load of the pressure-pipe does not act on the

connecting sleeve.

7.1.2 Transportable wet-well installation

In transportable wet-well installations, the pump

in the shaft is to be protected against tipping over

and slipping. (e.g. secure the chain with slight pre-

stressing).

NOTE:

If used in pits without a solid floor, the pump must

be placed on a sufficiently large plate or be sus-

pended in a suitable position on a rope or chain.

7.2 Electrical connection

WARNING! Risk of electric shock!

Electrical connection must be carried out by an

electrical installer authorised by the local power

supply company in accordance with the applica-

ble local regulations (e.g. VDE regulations).

• Check that the mains current and voltage comply

with the data on the rating plate.

Pos. Part description Pos. Part description

1 Cable assy 14 Capacitor

2

Head Cover 15 Gasket, Head Cover

3

Adaptor cover 16 End bracket (B)

4 Motorhousing 17 Rotor assy

5

Non-return valve 18 Stator

6

Pipe connection 1 ½" 19 End bracket (A)

7 Delivery port, Flange 20 Mechanical seal

8

Gasket, Flange 21 Oil drain plug with seal

9 Cover, Casing 22 Washer

10

Pump casing 23 Impeller

11

Floatswitch 24 Gasket, Casing

12 Cable holder 25 Strainer

13

Sealing, cable entry 26 Hose nozzle R1½ (outside thread)

Loading...

Loading...