WINCO / DWL Industries Co.6

Follow these same instructions for each well of a two well unit. Each well

operates independently and may be operated at dierent temperatures.

1. The EFT-32 requires the use of two cords. Be sure to unplug both

cords prior to moving, testing or repairing this product.

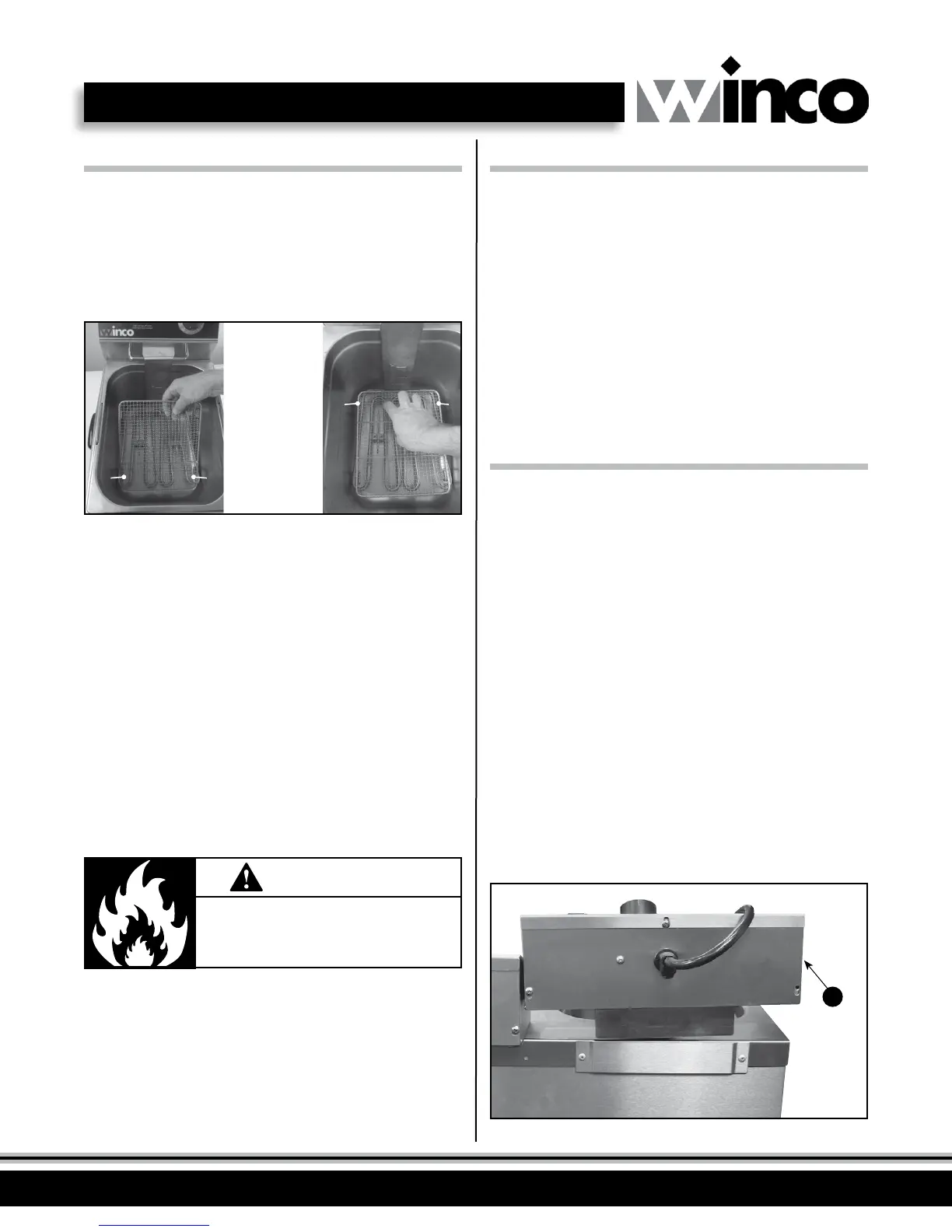

2. Remove basket(s) (I) from fryer.

3. Insert Wire Mesh Heating Element Cover (M) (Figure 5)

x

x Fire Hazard.

Overheated oil or oil vapors can ignite causing a re.

Monitor oil temperature, quality and level. Use and

maintain oil vapor removal system.

WARNING

Operation

4. Fill or add oil/solid shortening to the Well (F). Always maintain oil

level between High Oil Level (C) and Low Oil Level (D) as indicated

on the Element Holder Vertical Support Bracket (J).

(See Figure 1) DO NOT under-ll or over-ll.

5. Adjust the Thermostat Control Dial (A) to the desired temperature;

the Temperature Ready Light (G) indicates when the elements

are energized. If solid shortening is used, pack the fat around the

heating element and set the temperature between 200~250°F

so the fat will melt slowly as it covers the heating elements. The

melted fat should not exceed the high level mark nor should it drop

below the low level mark found on the Element Holder Vertical

Support Bracket (J). This will reduce smoking and risk of re.

6. Allow the oil to preheat and come up to recommended cooking

temperature. The Temperature Ready Light (G) will cycle o when

the oil has reached the set temperature.

Oil Tips

1. Use oil that is recommended for frying foods.

2. Cook at temperatures that are recommended by food manufacturer.

3. Change oil when oil becomes noticeably darkened from food

particles that burn when subjected to prolonged heat.

4. Change oil when there is a noticeable foul odor or when the oil

smells like the food cooked in it.

5. To re-use oil, use a few layers of cheese cloth to lter excess

particles only after oil has cooled.

6. Cover oil overnight using the Well Cover (M) provided.

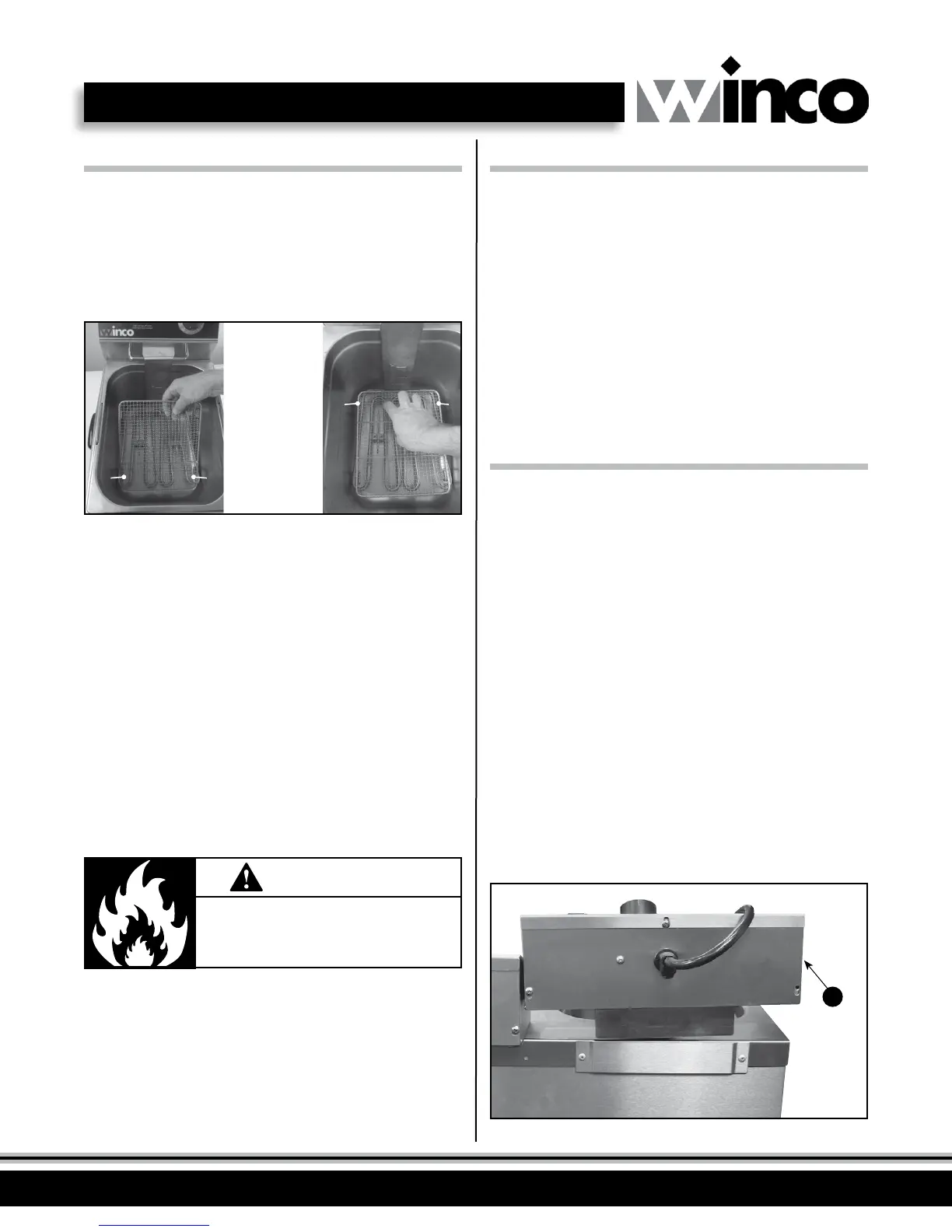

Safety Reset Switch

The units are equipped with a switch that cuts o power if the oil

temperature reaches 430°F (221°C). This switch has a manual reset.

The reset switch is located on the back of the unit (Figure 2).

The switch will activate if the oil temperature reaches 430°F. Before

resetting the safety switch, check for these causes.

Possible causes for the safety reset switch to activate are:

• Dirty oil

• Too little oil in fry well

• Heating elements not in proper lowered position

TO RESET THE TEMPERATURE SAFETY SWITCH:

1. Wait until the oil has cooled to 300°F (149°C) or below.

2. Remove the switch cover by unscrewing counterclockwise.

3. Use a pen or similar narrow tool and press the reset button down.

The button should stay in the depressed position.

4. Replace the switch cover and secure by screwing clockwise.

If unable to reset the safety reset switch or the safety reset

switch continues to trip, contact WINCO Technical Service.

Figure 6. Removing / Replacing Electrical Power Head

Removeable

Electrical Power

Head slips easily

into and out of

the holder on the

back of the unit

O

Figure 5. Insert Wire Mesh Heating Element Cover (M)

1. Place two rear

wire feet inside

heating element in

spot A.

2. Push two front

wire feet over

heating element at

the front, so feet

are just outside

the heating

element in spot B.

A

B

1. 2.

A

B

7. Dry food product or remove ice crystals from food prior to frying.

8. Load each basket; NEVER more than half way full.

9. Carefully lower the basket into the cooking oil. Food should

remain in fryer as per manufacturers recommended cooking time.

10. When food is nished, hook the basket on the Basket Support Bar

(K) using the Basket Hooks (L).

This will allow the excess oil to drain back into the well. Prepare

as directed by food manufacturer.

Loading...

Loading...