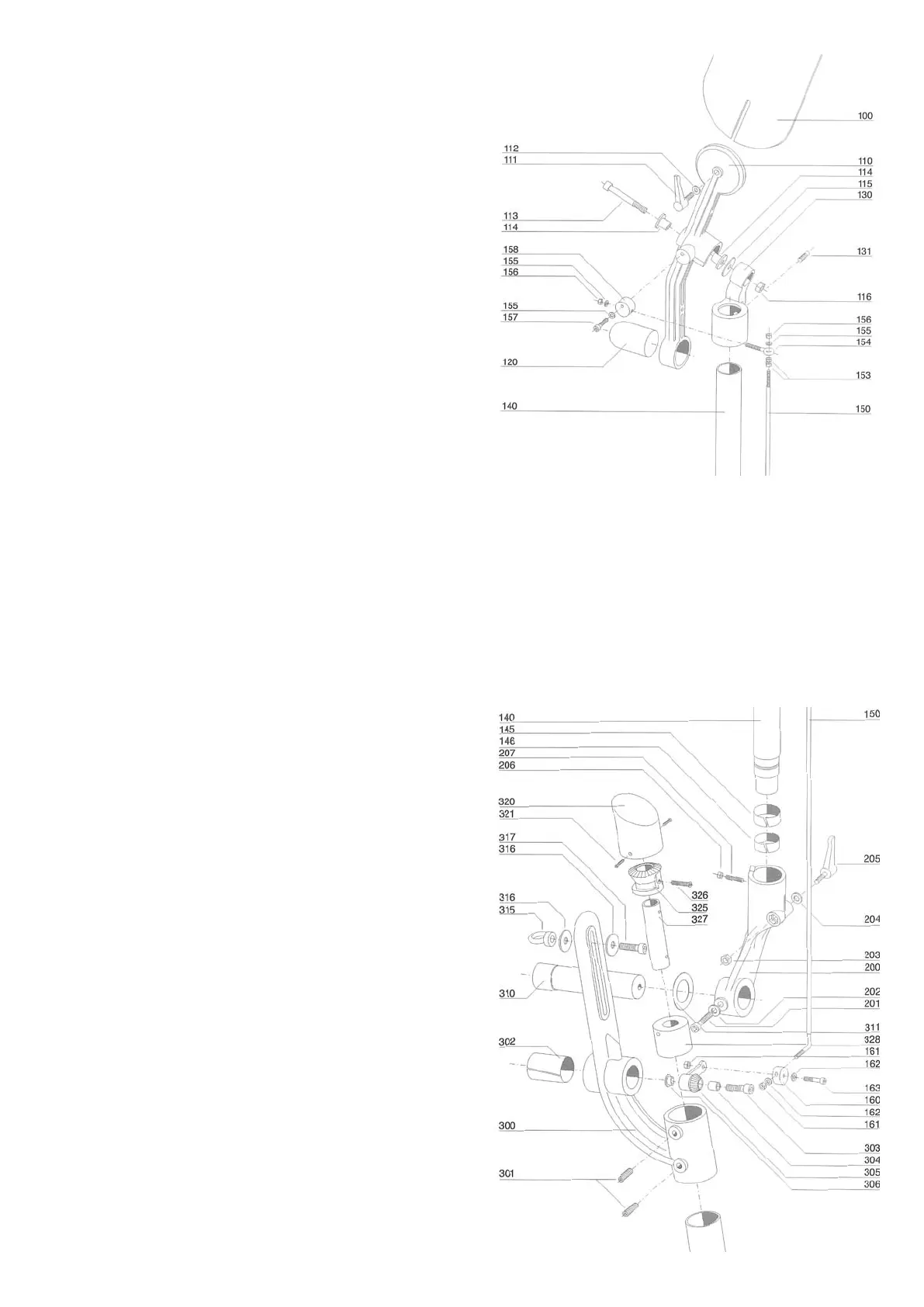

5.3.2 AT THE WINDVANE SHAFT

• Ifthewindvaneshaftwillnotturneasily(forcourse

adjustment) even when adjustment lever 205 is

released, remove locking screw 206/207 and raise

the windvane shaft.

• ApplyWD-40orTeflonsprayandreassemble,

taking care to ensure that bearing 141/142 is

properly positioned.

• Tightenlockingscrew206/207untilitstopsand

then loosen it slightly so that the windvane shaft

can turn freely. Screw 207 serves merely to hold

the shaft in place if the unit is lifted; it should not be

pressed hard against shaft 140.

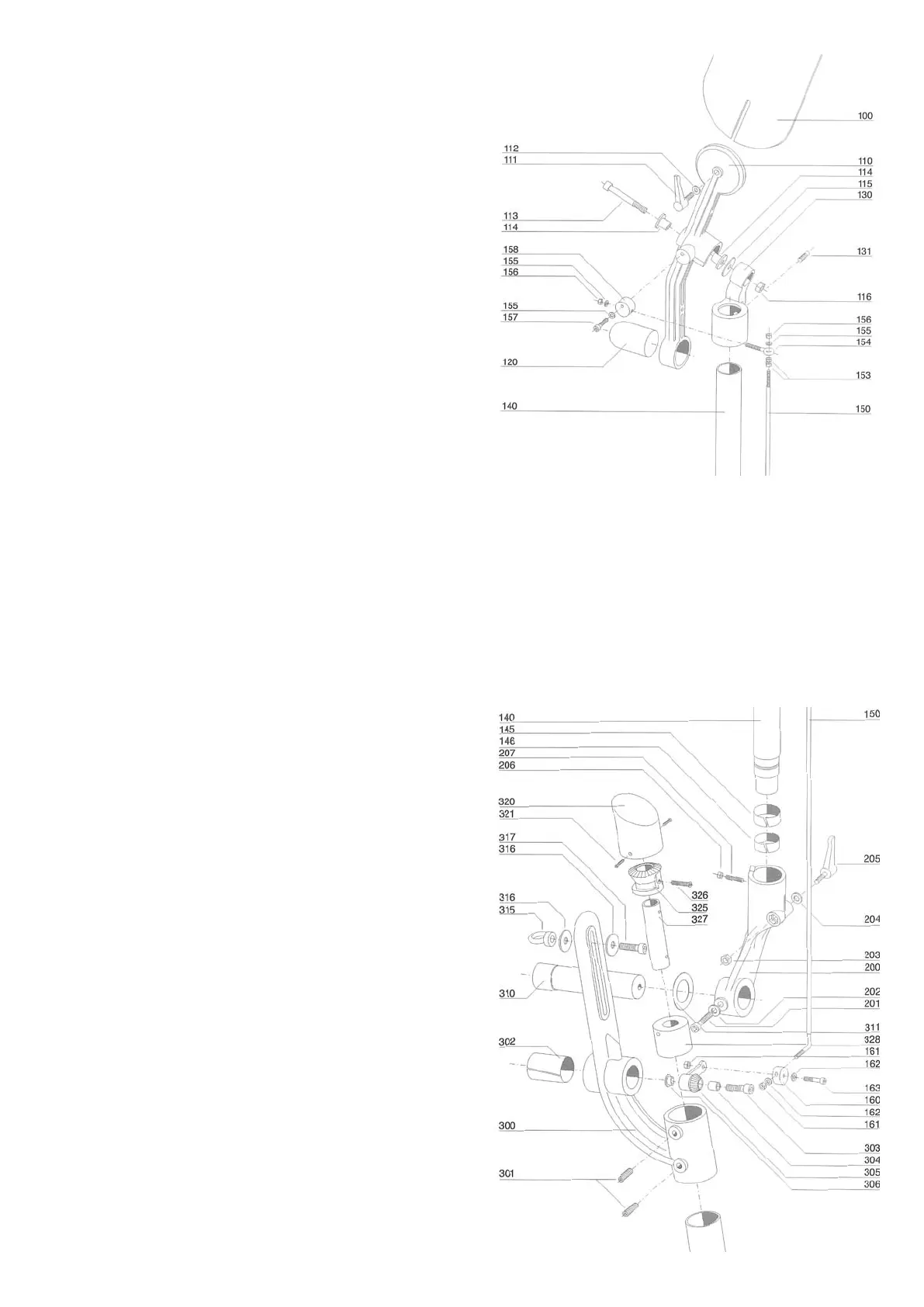

5.3.3 AT THE RUDDER AXLE

• Ifthereisfrictionattherudderaxle,thesystemwill

have to be disassembled and cleaned.

5.3.3.1 DISASSEMBLY PROCEDURE

• Removethesystemfromthetransom.

• Removeredcap320.

• Removescrew327.

• Pushshaft255downoutofbevelgear325.

• Marktherelativepositionsofthetwogearsinthe

bevel gear linkage.

• Cleanbearing328.

5.3.3.2 ASSEMBLY PROCEDURE

• Checkthepositionofthetwogears.Theleveron

thesmallgear305shouldbeinthe‘quarterpast

twelve’ position.

• Checkthatthependulumarmisvertical.

• Check that the pendulum rudder blade is in line

with the keel.

• Checkthattheholeinbevelgear325isflushwith

the hole in shaft axle 327.

5.3.4 AT THE STEERING LINES

• Dotheblocksmovefreely?

• Arethetransmissionpathstoolong?

• Isthewheeltoofarfromthetransom(centre

cockpit)?

• Arethemainrudderbearingsstiff?

• Isthewheelsteeringsystemstiff?

5.4 THE PUSH ROD IS BENT

• Checkthebalanceproportionofpendulumrudder

blade 440 (see 1.7 The Pendulum Rudder).

• Thepushrodcanbestraightenedeasily.

5.5 THE WINDVANE SHAFT IS LOOSE

• Tightenbolts205

Loading...

Loading...