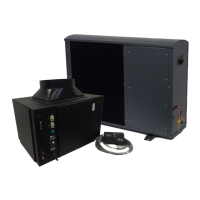

Ducted and Ducted Vertical

Wine Cellar Cooling Systems

Installation, Operation and Maintenance Manual

60Hz Models: D025, D050, D088, D0200, D050V, D088V

50Hz Models: WG40, WG75, WG100, WG175

Manufactured by:

Syracuse, NY

wineguardian.com airinnovations.com

Wine Guardian reserves the right, without notice, to make changes to this document at its sole discretion.

Please visit our web site for the most current version of the Wine Guardian manual and other literature.

Wine Guardian is a registered trademark (2,972,262) of Air Innovations, Inc.

Edition 02-2019 (Original Instructions)

© Air Innovations 2019

Part No. 15H0127-00