Commissioning

Coolingcoil

(cold water)

Before commissioning the air-handling unit, check the entire pipework for leaks.

- Vent the heat exchanger and the pipework.

- Ensure that condensate can drain off, to prevent the condensate tray from

overowing.

- If appropriate, before commissioning a chilled water cooling coil check whether the

antifreezeconcentrationinthechilledwaterisadequatefortheanticipatedtemperature

range.Whenantifreezeisaddedtothechilledwater,thecoolingcoil’spowerdecreases

inproportiontotheincreaseinantifreezeconcentration.

Theminimumairowvelocityovertheelectricheatingcoilis1.5m/s(otherwiseriskof

overheating).

If the motor is of the multi-speed or variable-speed type, irrespective of the heating power

oftheelectricheatingcoilitisimportanttoensurethattheairowvelocitydoesnotdrop

belowthespeciedminimumevenwhenthemotorisoperatingatitslowestspeed.

It is permissible to install an electric heating coil on the intake side (upstream of the drive

motor/fanasviewedinthedirectionofairow)onlyiftheheatingcoil’sairdischarge

temperaturedoesnotexceed40°C.

Always comply with the applicable safety regulations for electric heating appliances.

Always ensure that the electric heating register shuts down automatically if

the air ow stops. In addition, the electric heating register must be switched

by one or more switching devices (contactors) having a control circuit wired

through the series connected safety temperature limiter. Ensure that at least

one safety temperature limiter is installed at the top inside of the heating coil.

Ensure that the electric heating register is protected against humidity and water.

Note

Note

Electricheatingcoil Topreventoverheating,ensurethattheairowratescomplywiththeminimumvalue

speciedbelow(guresareinm³/h):

Appliance type AHU TE/AHUW TE 21/43 64/96 130/170 210/270 320/380 450

2200 3200 5700 9000 12500 22500

Heatingcoil

(warm water/hot water/steam)

Before starting the air-handling unit, check the entire pipework for leaks.

- Vent the heat exchanger and the pipework.

- Ensure that condensate can always drain freely from steam registers, to prevent

steam hammer from damaging the register.

- To prevent overheating due to inadequate heat transfer, ensure that the fan is running

before you switch on the heating water pump or open the water/steam valve.

- Check the air discharge temperature; max. air discharge temperature with heating

coilonintakesideis40°C;otherwiseriskofmotoroverheating.

Alwaysbearinmindthatsurfacesofheatexchangersandconnectingadaptors

become hot.

Riskofburnsandscalding.

Plate-typeheatexchanger

withdampers

The recirculating air damper must be open and the bypass damper must be closed if

a plate-type heat exchanger with bypass dampers (and extra recirculating air damper)

operates in recirculating air mode. This means that the fresh air induced into the system

is preheated. The outside air damper can be partially closed in recirculating air mode.

Closing the bypass damper means that the outside air is preheated. Opening the bypass

damper provides a means of defrosting the plate-type heat exchanger if ice forms in winter.

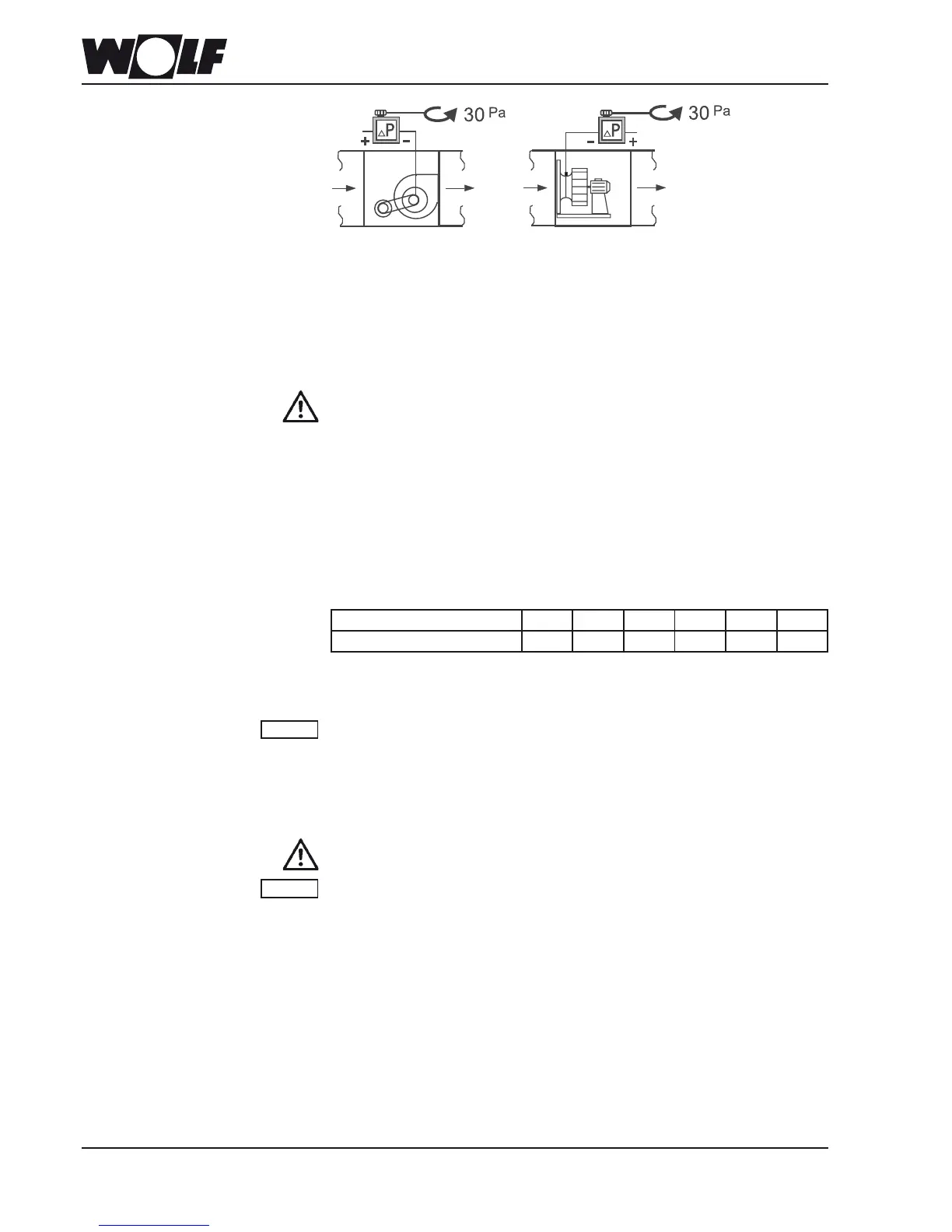

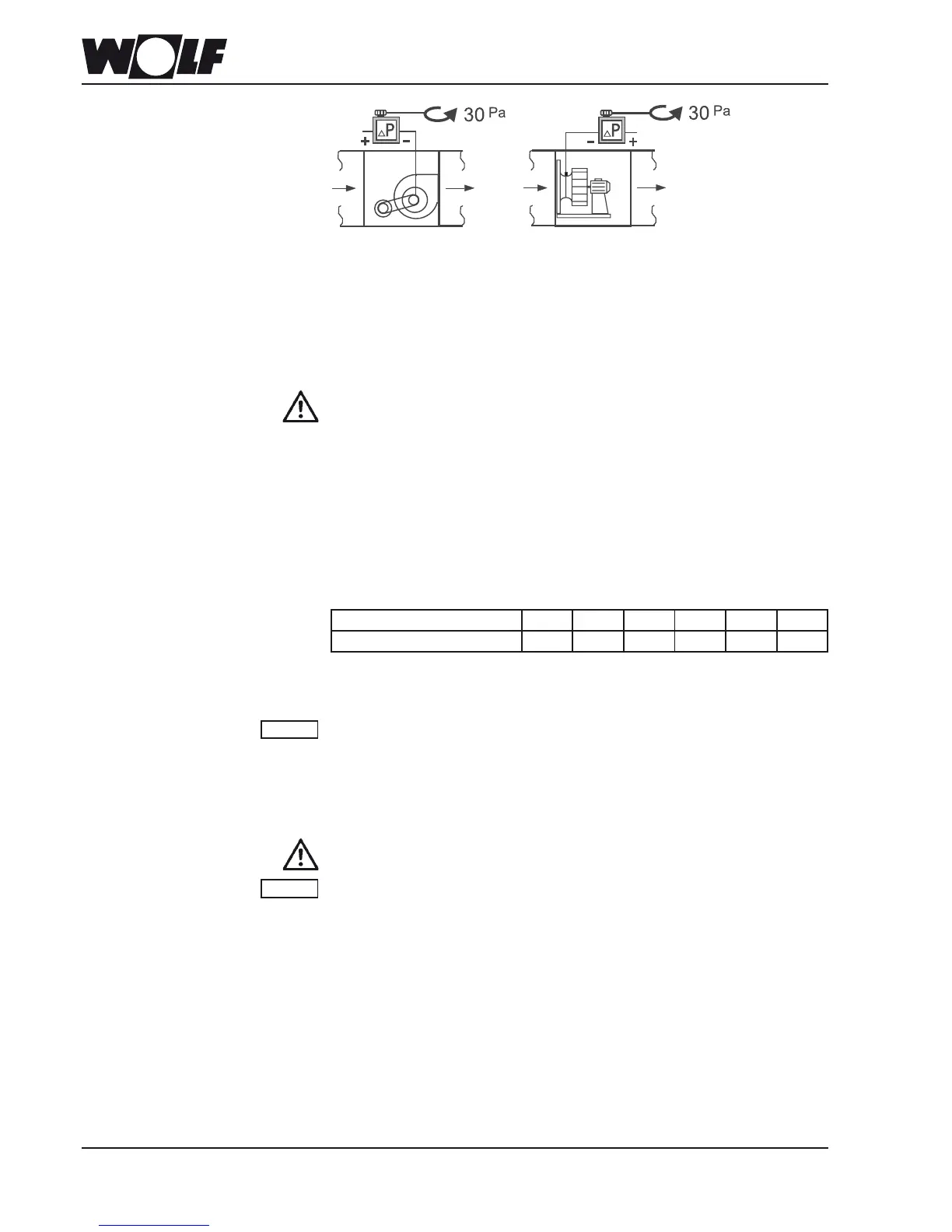

Flow rate monitor

Loading...

Loading...