19

3062049_201610

KG TopInstallationinstructions

Flexibleconnections

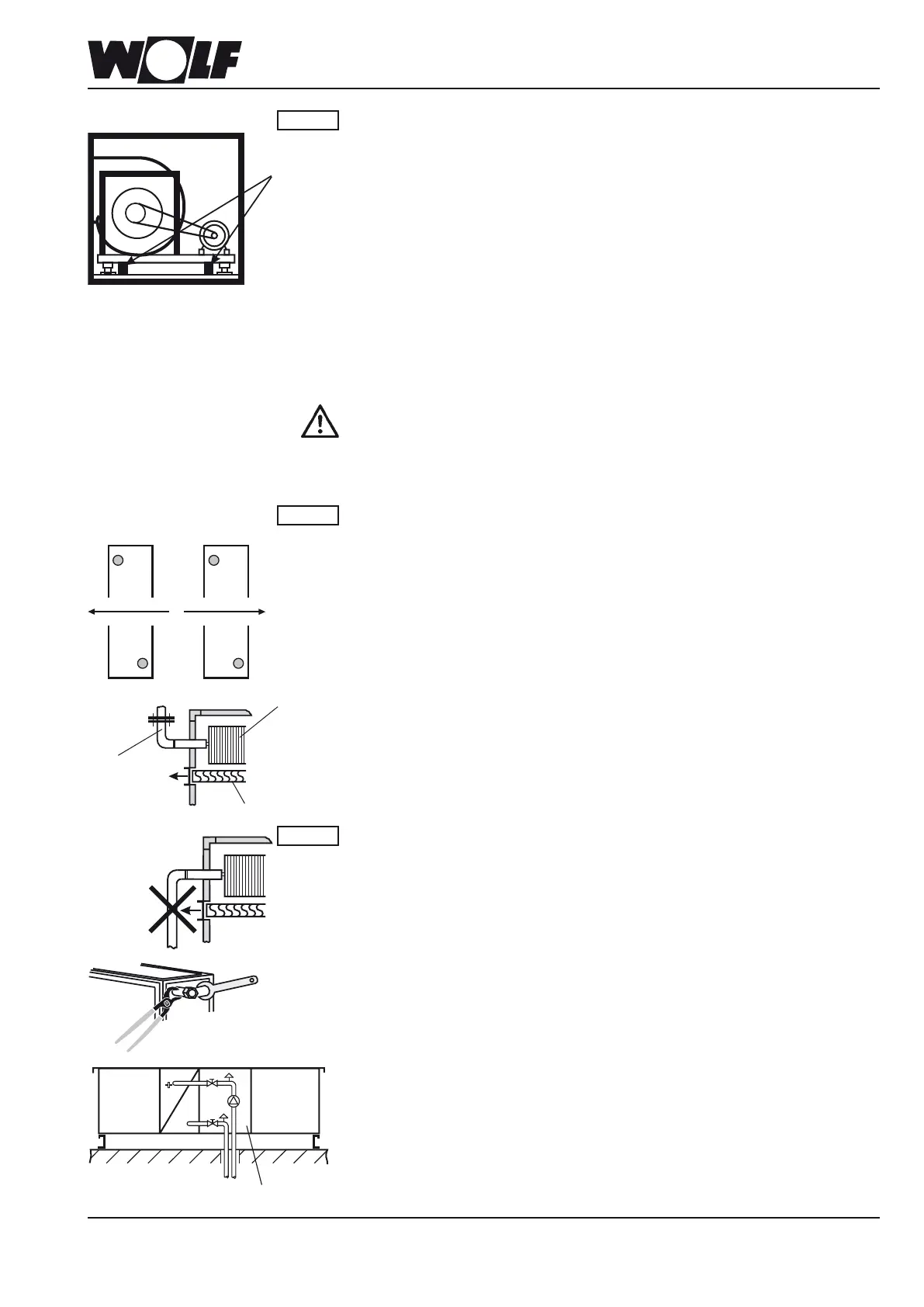

Remove the transportation locking devices.

Duringinstallationensurethattheconnectingangesarenomorethan100mmapart

toensurethattheexibleconnectionshavetheirfullrangeofmovement.

It may be necessary to fully insulate the exible connections on site against

acousticemissionsandcondensation.

Ensurethatthefanshaftishorizontalinitsbearings.Iftheshaftisnotperfectlyhorizontal

the ball bearing will suffer damage and service life will be substantially reduced.

Remove the transportation locking devices from fans mounted on spring-loaded vibration

dampers.

Note

Fansection

Transportation

locking devices

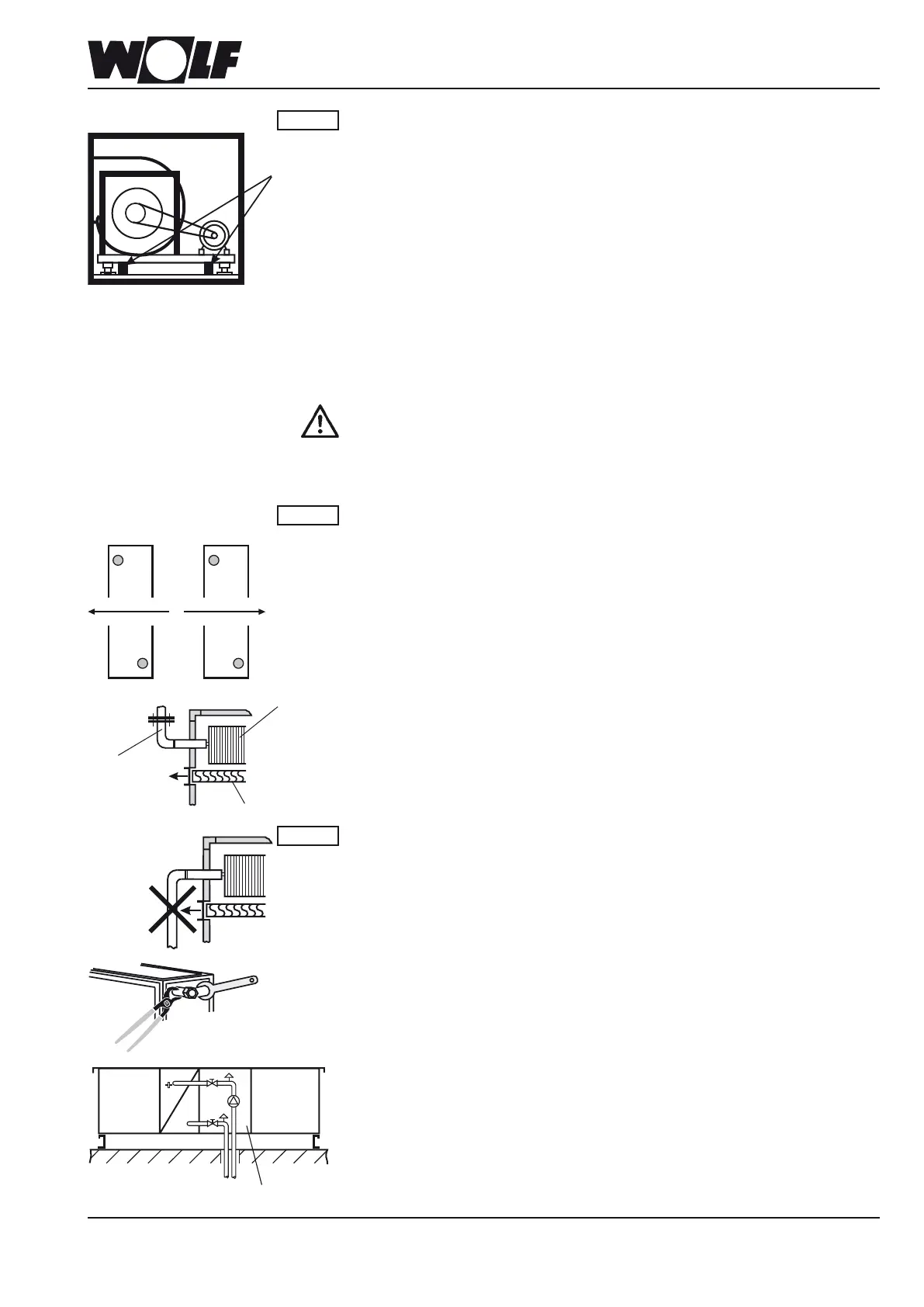

The heat exchangers (cooling coil, heating coil) operate on the countercurrent principle.

This means that the heat transfer medium or refrigerant moves in the opposite direction

totheairow.Consequently,theowconnectionforthemediumisalwaysontheair

discharge side of the heat exchanger.

Connect the heat exchangers so that no mechanical stresses and strains are transmitted

from the pipework to the heat exchangers.

It is also important to ensure that the transmission of vibrations and longitudinal expansion

and contraction between the air-handling unit and the pipework is effectively prevented.

Ensure that the connecting lines never obstruct access to the other parts of the unit

(fan,lter,scrubber,etc.).

For the heat exchanger(withange)it is recommended to use bends to make the

connections.Thiscongurationwillensurethattheheatexchangerandthemisteliminator

can be extracted to one side for subsequent cleaning.

Always install steam registers so that the steam inlet is always at the top (large diameter

connector) and the condensate drain is always at the bottom.

When connectingtheow and return lines, alwaysusea wrench of correct sizeto

counterhold the threaded connectors of the heat exchanger. Otherwise the mechanical

force could separate the header from the heat exchanger. Damage of this nature would

effectively ruin the heat exchanger.

It is important to ensure that facilities for venting and draining are installed on site.

Always connect a siphon to the condensate drain connector of the cooling coil drip tray

(see "Siphon").

KGW: If the heat exchanger connections are on the inside, run the pipework through

the empty section provided for the purpose downstream of the heat exchanger.

Make adequate provision for venting.

Make suitable apertures through the removable base to accommodate the pipes.

Seal these apertures by suitable means after insulating the pipework.

The weatherproof projection is not thermally insulated. Consequently,thepipes

andvalvesmustbeadequatelyinsulatedand,ifnecessary,heatedonsite.

Ifaninverterisusedforoperationitisadvisabletoprovideexternalventilation

insummertopreventoverheating(max.permissibletemperature45°C).

Providesuitableaperturesthroughtheremovablebaseoftheprojection

toaccommodatethepipes.

Note

Note

Heat exchanger

Removable heater exchanger

Flange

Removable mist eliminator

Empty section

Flow

FlowReturn

Return

Directionofairow

Directionofairow

+

Loading...

Loading...