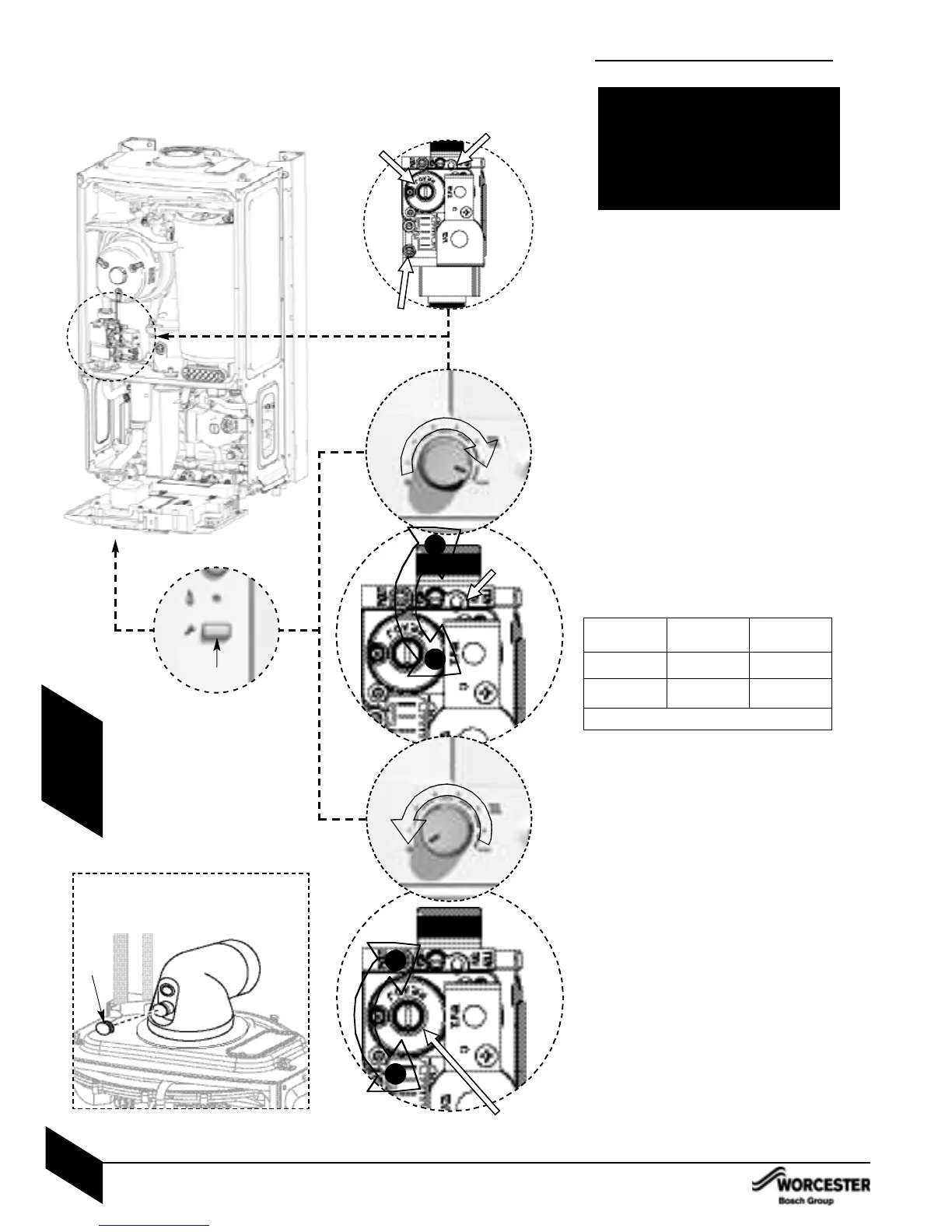

SETTING THE AIR / GAS RATIO

FOR THE SIT 848.093 SIGMA

THIS PAGE SHOWS THE SETTING PROCEDURE FOR THE SIT VALVE

FOR ALTERNATIVE VALVE SEE PAGE 55 DUNGS.

30. Setting the CO/CO

2

Note: When running in the service mode, the

boiler will operate both the central heating &

DHW circuits. This is to allow sufficient time for

the setting procedure. It will be necessary to run

sufficient water through the DHW circuit to

ensure that the boiler will not cycle on low

heating demands.

30.1 Connect manometer to inlet pressure point

on the gas valve.

To adjust the CO/CO

2

it will be necessary to

first operate the boiler at maximum output.

Press and hold down the service button (A) for

10 seconds until illuminated. The blue power

indicator will flash.

30.2 Turn central heating control to maximum;

the boiler will then go to maximum output.

NOTE: The control will resume normal operation

after 15 minutes or if the service button is pressed

for over a second.

30.3 Using a 2.5mm allen key set the CO/CO

2

via adjuster (B) using the table below.

Check CO is less than 200ppm.

Measure the inlet pressure; it should be no

less than 18.5mb NG or 37mb for LPG.

30.4 Set the central heating control to minimum.

The boiler will go to minimum power.

30.5 Measure the CO/CO

2

and check against the

table above. If required adjust (C) on the gas

valve until the correct measurement is set.

Remove brass dust cap with flat bladed

screw driver. Then using a 4mm allen key

adjust CO

2

. Replace dust cap.

Check that the CO is less than 200ppm.

Return to maximum and re-check the

CO/CO

2

. If correct press and hold down the

service button for 2 seconds; the button will

cease to be illuminated and the blue power

indicator will be permanently illuminated.

Remove manometer and re-seal inlet pressure

point on gas valve.

Re-assemble and refit boiler case.

30.1

30.3

30.5

30.4

Inlet Test Nipple

Min

‘C’

Max

‘B’

Min

‘C’

Max

‘B’

+

I

30.2

A

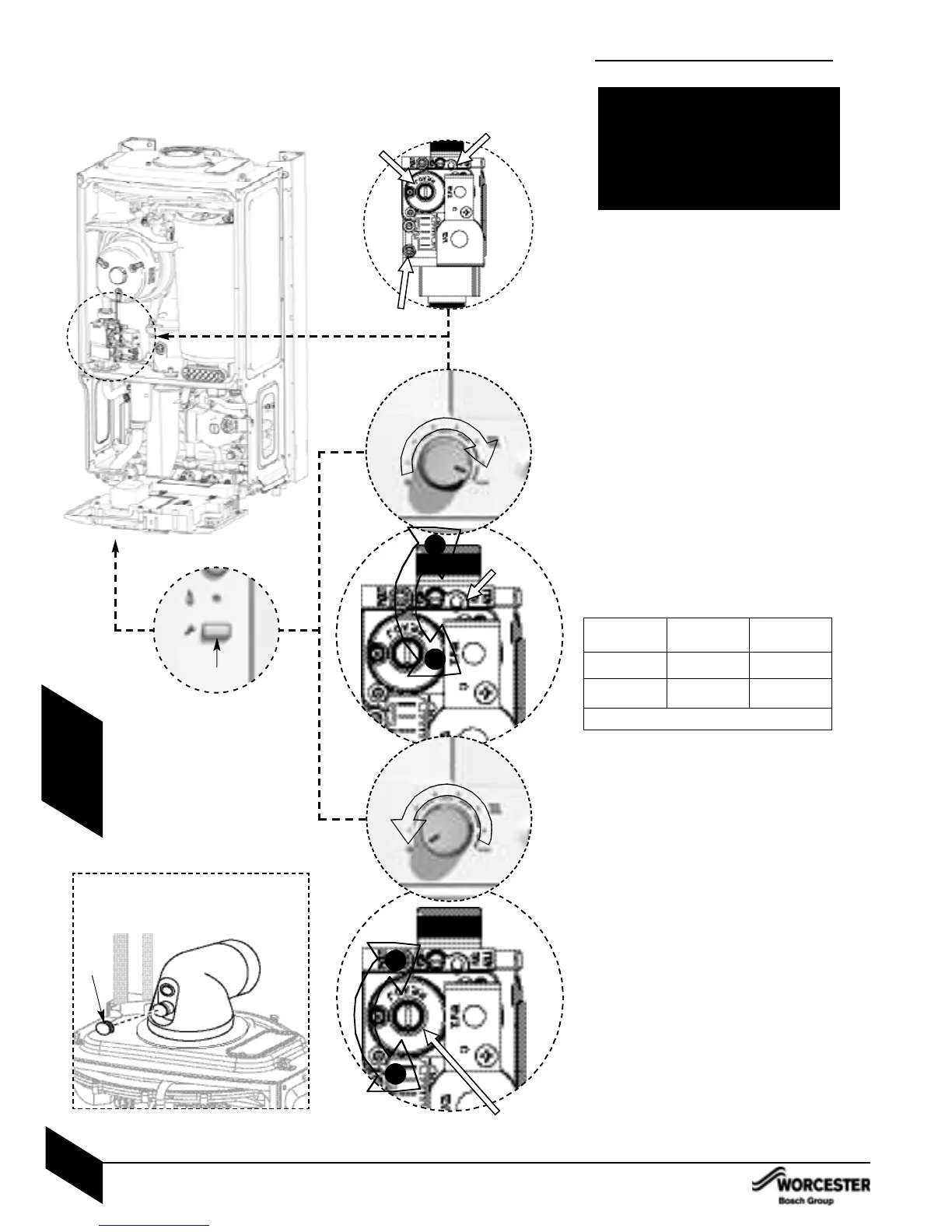

Please note: The flue gas test point can be

accessed on the appliance flue elbow by

removing cap D

D

+

I

Gas type

CO/CO

2

settings for Greenstar Si

NOTE. CO/CO

2

should be measured

after 10 minutes

Natural gas

LPG

9.8% ± 0.5%

11.0% ± 0.5%

9.2% ± 0.5%

10.5 % ± 0.5 %

CO

2

setting

maximum

CO

2

setting

minimum

CO - less than 200ppm (0.002 ratio)

REPLACEMENT OF PARTS

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR 25Si/30Si

8 716 115 165a (06/2008)

54

SERVICING

& SPARES

THE SETTING OF THE GAS RATIO MUST BE

CARRIED OUT BY A COMPETENT PERSON.

SETTING OF THE GAS RATIO MUST NOT BE

ATTEMPTED UNLESS THE PERSON

CARRYING OUT THE CONVERSION IS

EQUIPPED WITH A COMBUSTION ANALYSER

CONFORMING TO BS 7927 AND IS

COMPETENT IN ITS USE.

Loading...

Loading...