SERVICING

& SPARES

INSTALLATION & SERVICING INSTRUCTIONS

42

SETTING THE GAS/AIR RATIO

6-720-611-730b (12.05)

SETTING THE GAS/AIR RATIO

5 Measure the CO

2

level.

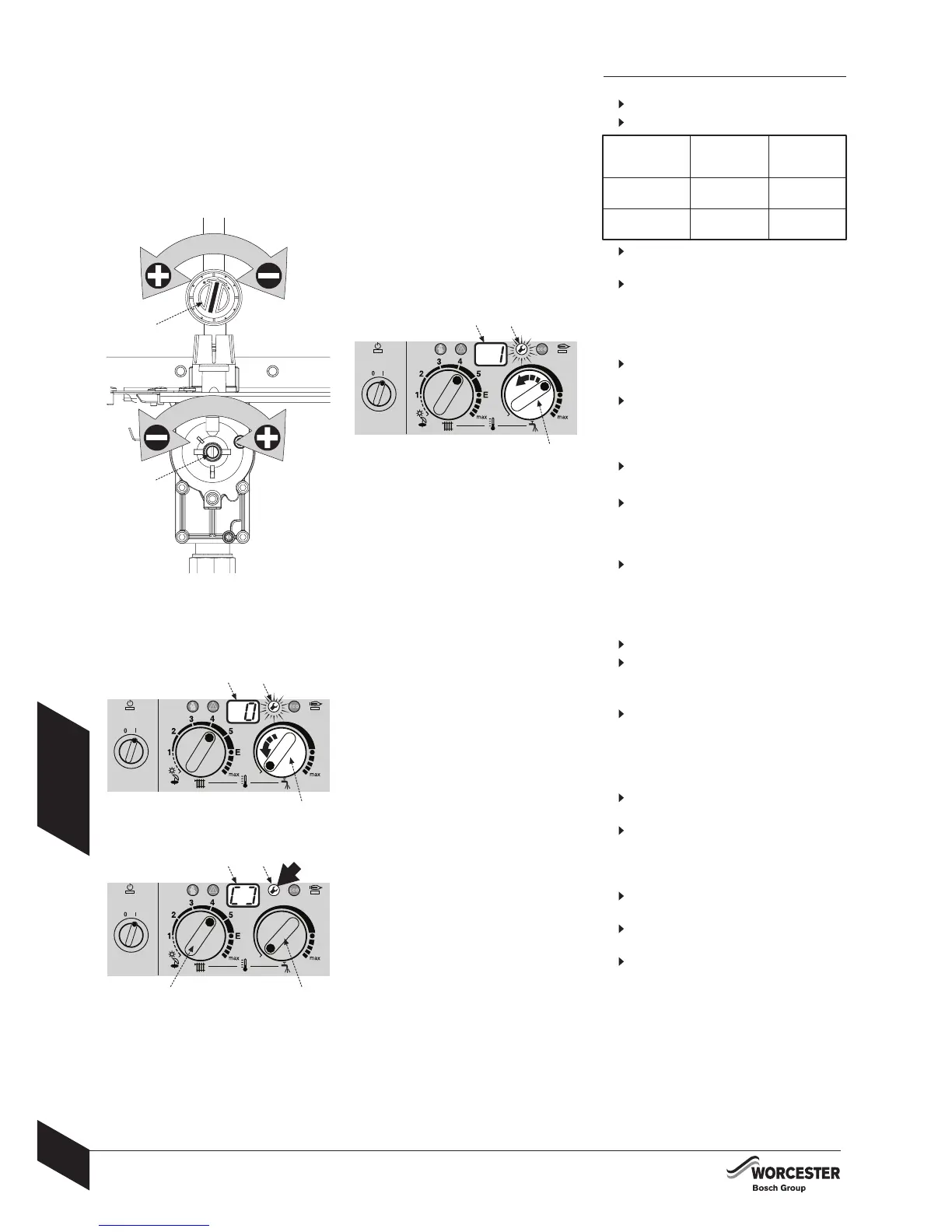

Prise off the seal on the gas flow restrictor.

Adjust the gas flow restrictor (F) to obtain the

CO

2

level given in the table above.

Measure the CO level.

If the CO level is over 200ppm, the gas

volumetric flow rate is too high. Reduce the gas

flow rate on the adjustable gas flow restrictor

until the CO level is below 100ppm.

Re-adjust the CO

2

level if necessary.

6

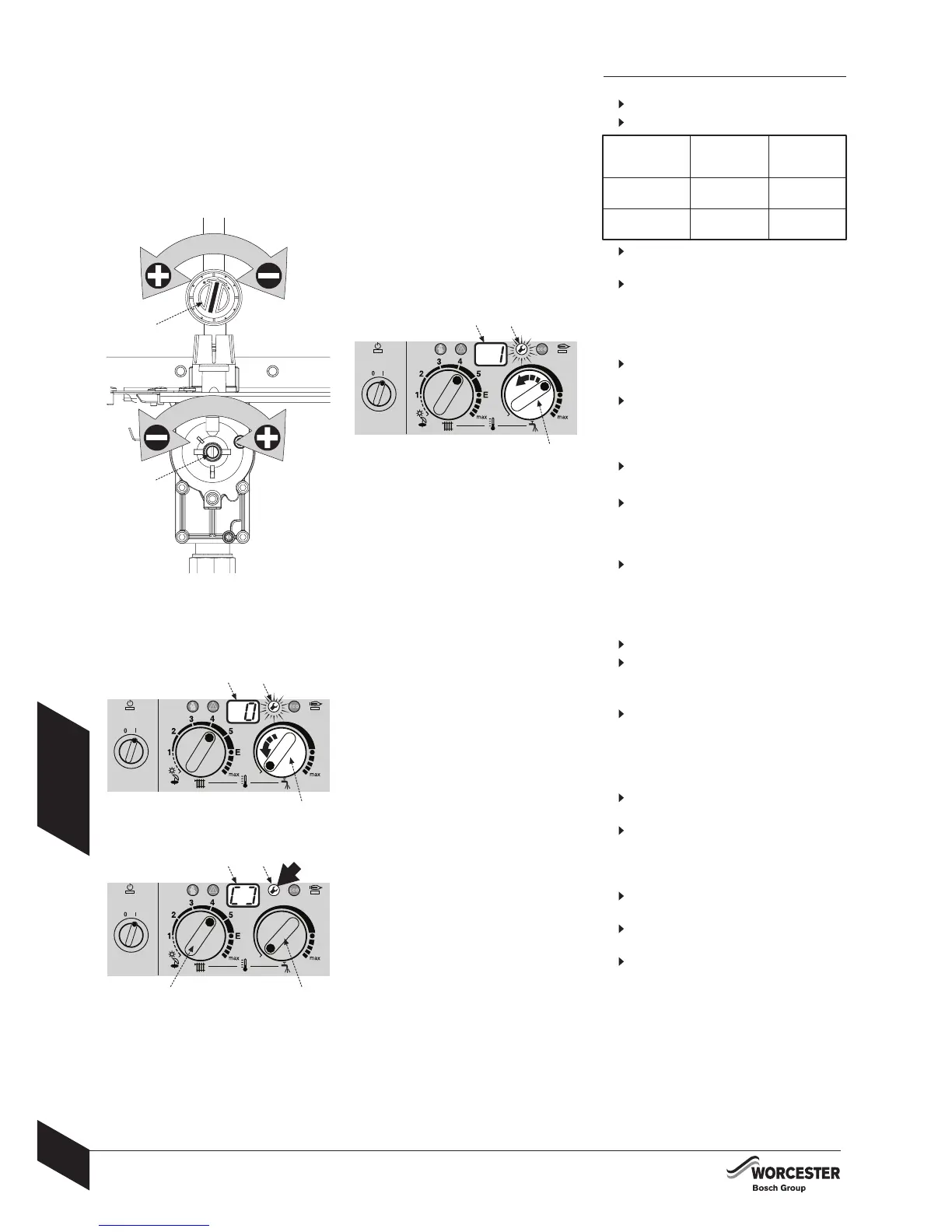

Turn the temperature control (E) anti-clockwise

until the display (C) shows 1 (= min. rated heat

output).

The display and the button (B) will flash.

Measure the CO2 level.

7 Remove the seal from the gas valve adjusting

screw (G) and adjust the CO

2 level to the figure

given in the table above for min. rated heat

output.

Measure the CO level.

If the CO level is over 200ppm, the gas

volumetric flow rate is too high. Reduce the gas

flow rate on the gas flow restrictor (F) until the

CO level is below 100ppm.

Re-adjust the CO

2

level if necessary.

Re-check the levels at min. and max. rated

heat output and re-adjust if necessary.

8

Turn the temperature control (E) anti-clockwise

as far as the stop so the display shows 0 (=

Normal operating mode).

The display (C) and the button (B) will flash.

9

Press and hold the button (B) until the display

(C) shows [ ].

Reset the temperature controls (D) and (E) to

their original positions.

The display (C) will revert to the CH flow

temperature.

Remove testing probe from the flue gas testing

point and refit sealing plug.

Re-seal gas valve adjusting screw and gas

flow restrictor.

Replace outer case and secure.

CB

9

7

C

8

B

E

5

F

GAS TYPE

CO

2

reading

at max. rated

heat output.

CO

2

reading

at min. rated

heat output.

Natural Gas

Type H (G20)

LPG (propane)

(G31)

9.2 ±0.2% 8.8 ±0.2%

10.8 ±0.2% 10.5 ±0.2%

G

C

B

E

6

ED

Loading...

Loading...