Which WORK SHARP™ Port Should I Use?

Chisels &

plane blades up

to 1

5

/

8

"

Carving tools,

screwdrivers,

detail

sharpening

Putty knives,

scrapers,

axes, hatchets

and other flat

blade tools

General

grinding

Sharpening Port

X

Edge-Vision

TM

Port

X X

Topside Freehand

X X

4

Selecting the Right Abrasive for the Job

Either solid or slotted abrasives can be

used for grinding and sharpening tasks.

• For damaged tools or heavy grinding:

Use the coarse solid abrasive for

fastest results.

• For light grinding tasks: Use the fine

solid abrasive.

• For Edge-Vision™ Grinding: Use the

coarse slotted abrasive.

• For Edge-Vision™ Sharpening: Use

the fine slotted abrasive.

About WORK SHARP™

Abrasive Technology

Finish

• Coated abrasive disks start flat and

stay flat. (Bonded abrasives used in

stones and most power systems re-

quire frequent dressing to keep the

wheel flat.)

• The grit size is engineered to provide

optimal sharpness and surface finish

at each stage of sharpening. (Users

who are interested in a “utility sharp”

edge will find exceptional edge perfor-

mance on the faster coarse grits.)

Speed

• The abrasive selection is integrated

with design of the WORK SHARP™

drive train and cooling system to pro-

vide the fastest material removal rate

while minimizing the risk of overheat-

ing tool steels.

• The sharpening port includes a dia-

mond lapping abrasive that provides

superior burr control and allows for

1-step re-sharpening.

Simplicity

• Accepts readily available standard

150 mm or 6" adhesive–backed abra-

sives with trimming. (No custom abra-

sives or expensive custom wheels

required. Coarse grits are available at

most hardware/woodworking stores.

Fine grits are readily available at any

automotive paint supply store.)

• Slotted abrasives are available through

a Work Sharp retail outlet or direct

from Work Sharp.

5

Sharpening Tips

Sharpening Port Tips

When sharpening chisels and plane

blades up to 1

5

/

8

"

wide

• Choose Coarse Grit for damaged or

chipped tools

• Choose Fine Grit for re-sharpening tools

• Chisels under ½" wide should be sharp-

ened on the left side of the sharpening

port.

• Chisels wider than ½" should be sharp-

ened on the right side of the sharpening

port.

• Leave fence loose enough against chis-

el so the chisel can slide between the

fence and guide rail.

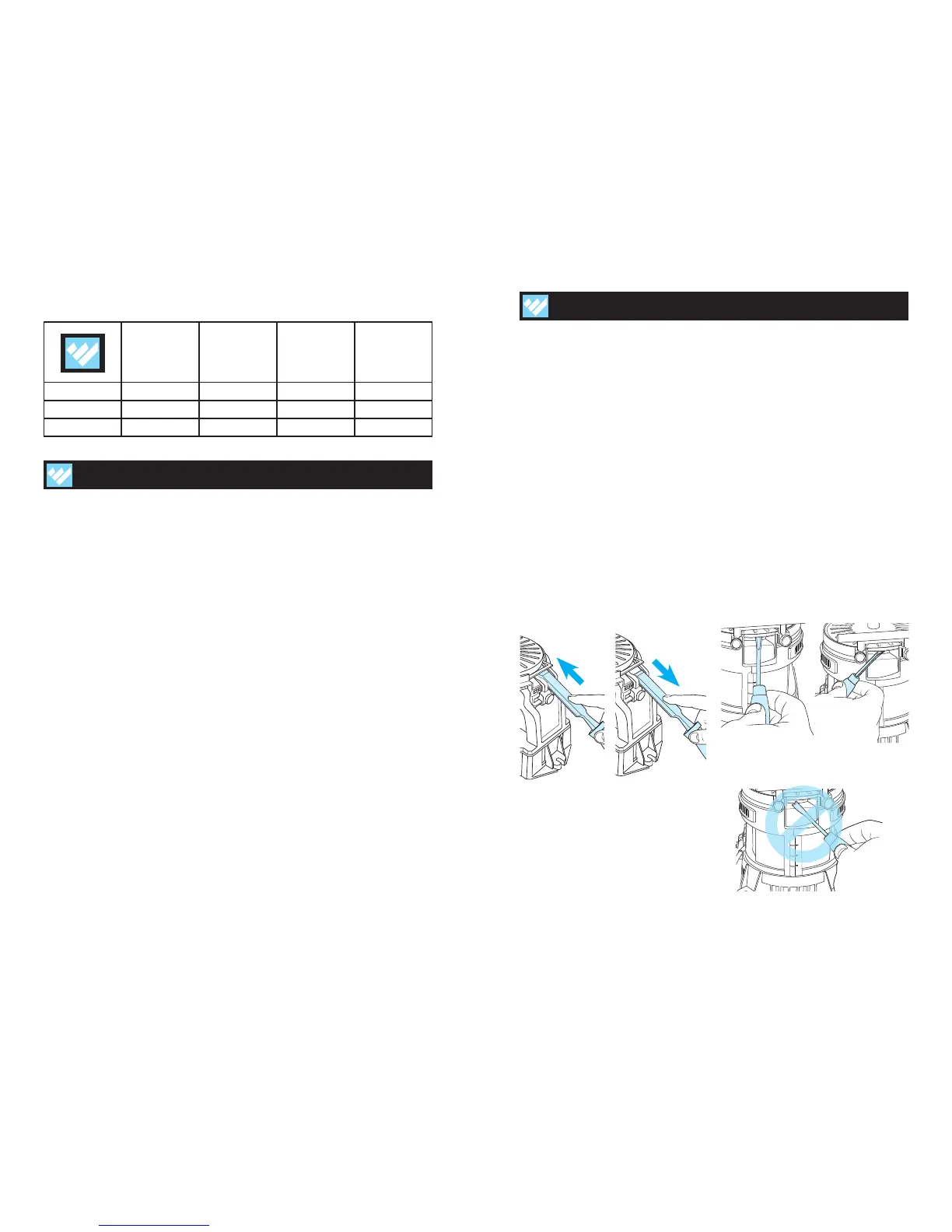

• “Plunge and pull” method in sharpen-

ing port will yield best results. Contact

wheel for only ½–1 second.

• Do not leave chisel against abrasive

wheel for longer than 1 second, or you

may risk overheating your tools.

• Keeping chisels flat on the sharpening

port diamond lapping plate will ensure

burr removal, optimum heat control and

proper bevel edge sharpening.

Edge-Vision

TM

Underside

Sharpening Port Tips

When using the Edge-Vision

TM

slotted wheel

• Use a permanent marker to color the

edge of your tool to be sharpened. This

will help you better see the edge you are

sharpening.

• Shine a shop light or drop light onto the

top of the unit to better see through the

slotted wheel.

• Sharpen tools with the cutting edge

at the 12:00 or 2:00 position, and not

10:00. This will ensure you are sharpen-

ing your tools edge with the wheel spin-

ning away from you for optimum safety

and control.

Plunge

Pull

Correct 2:00

position

Correct 12:00 position

Incorrect

10:00

position

Loading...

Loading...