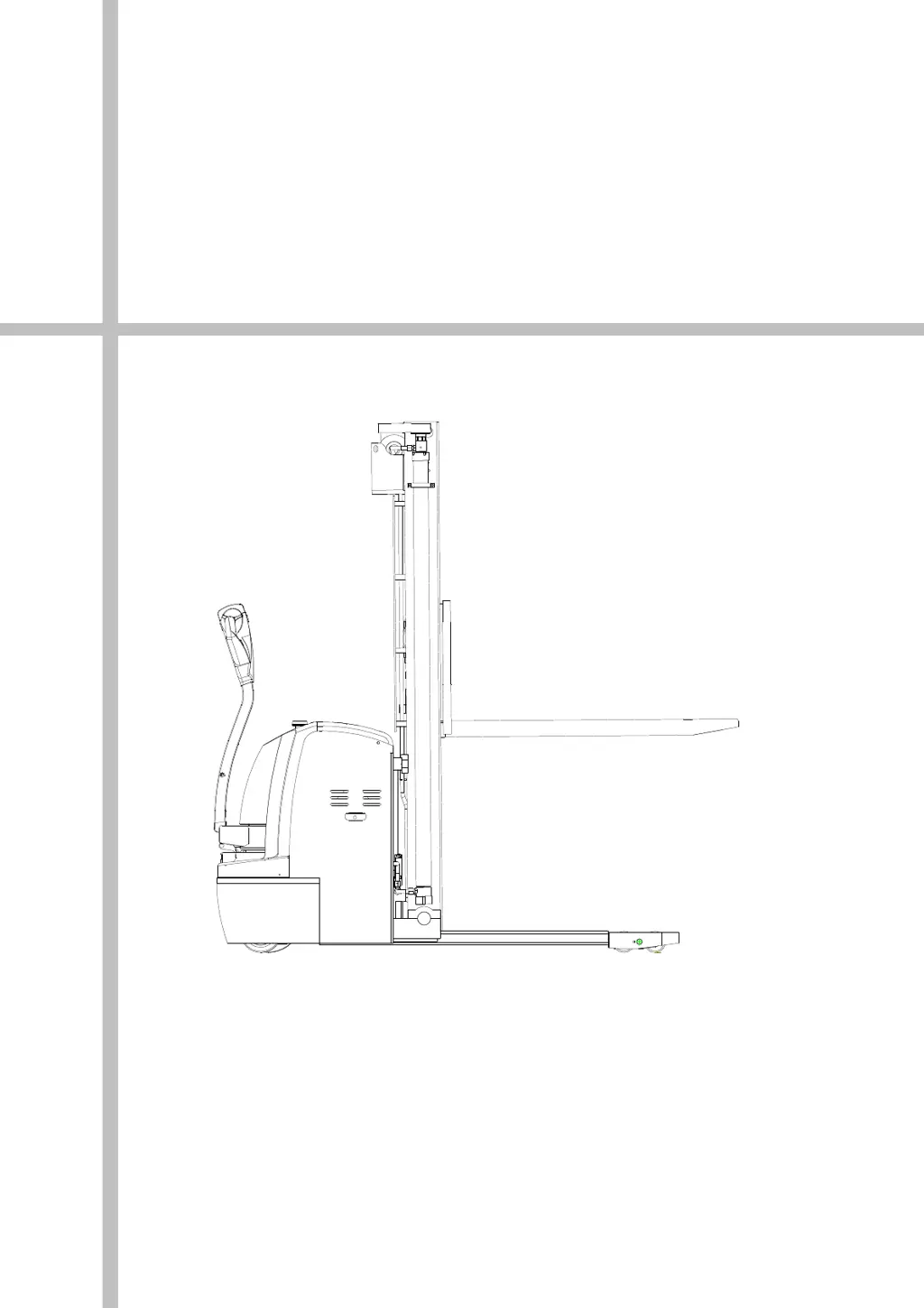

What to do if my Xilin Forklifts stacker can not stop during traveling?

- JJohn FloydAug 10, 2025

If your Xilin Forklifts stacker doesn't stop while moving, immediately cut off the power and replace the contact due to a broken contact preventing reset.