2

Focusing on Laser Imaging and Decorating

smooth cuts. e square dot shape is superior to other lasers,

such as the Ortur Laser Master 2 Pro, which is rectangular.

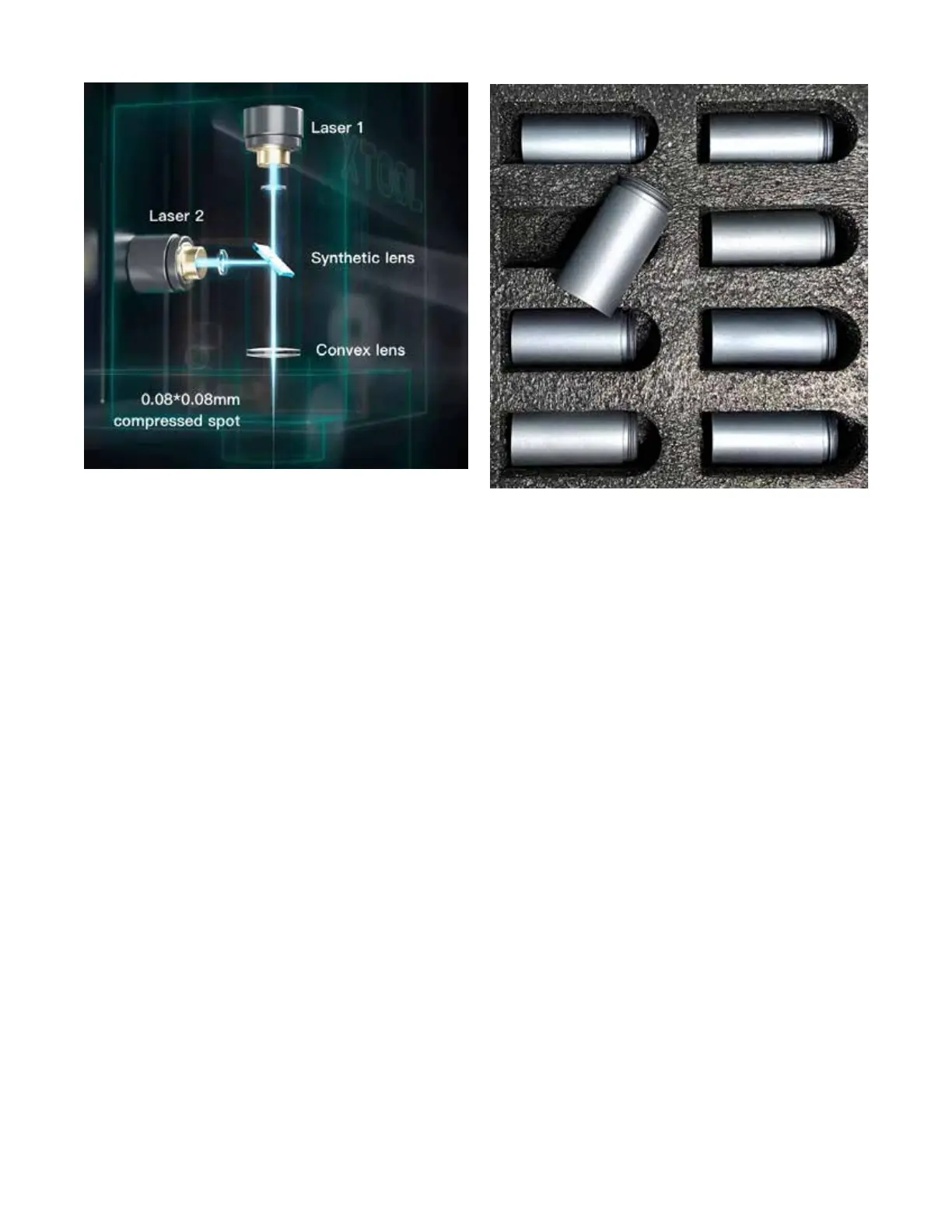

FIG. 3. xTool rates the power of the two 5W laser beams combined

to be equivalent to a single 15W laser cutter. Credit: xTool

e work area of the D1 is about 17” x 16” which is more than

sufficient for accommodating most of the projects that would

be appropriate for such a device. Despite its size it weighs only

about 5kg (about 11 pounds), meaning that it can be moved and

repositioned easily by one person.

e D1 is provided with legs that raise it off of the worksurface

to accommodate a range of workpiece thicknesses. e space on

all four sides of the frame allows the user to slide materials into

the active work area. Additional-cost legs can be purchased to ex-

tend that height to allow for the additional space as required for

a rotary device. ese optional legs screw easily into the attached

base legs and match their size and color (FIG. 4).

Another unique element of the laser head is a built-in red cross-

hair light that indicates where the laser will fire. is indicator

is safe to view without safety goggles, and despite the fact that it

is offset from the actual laser lens, the software accounts for this

discrepancy and properly positions the laser when firing. Users

should not underestimate the importance of accurately aligning

the laser head in relation to the workpiece.

Safety. e D1 was designed to provide an effective, efficient

work experience with safety considerations built-in. e bottom

of the laser head, closest to the workpiece, is surrounded with

a light shield. e shield, a custom-fit piece of orange acrylic,

allows the user to easily see that the laser is functioning, and pro-

tect others in the vicinity who may not be wearing safety goggles.

Of course, proper eye protection should be worn by everyone

within the work environment. e operation of the laser will

stop automatically when the machine senses movement or a tilt,

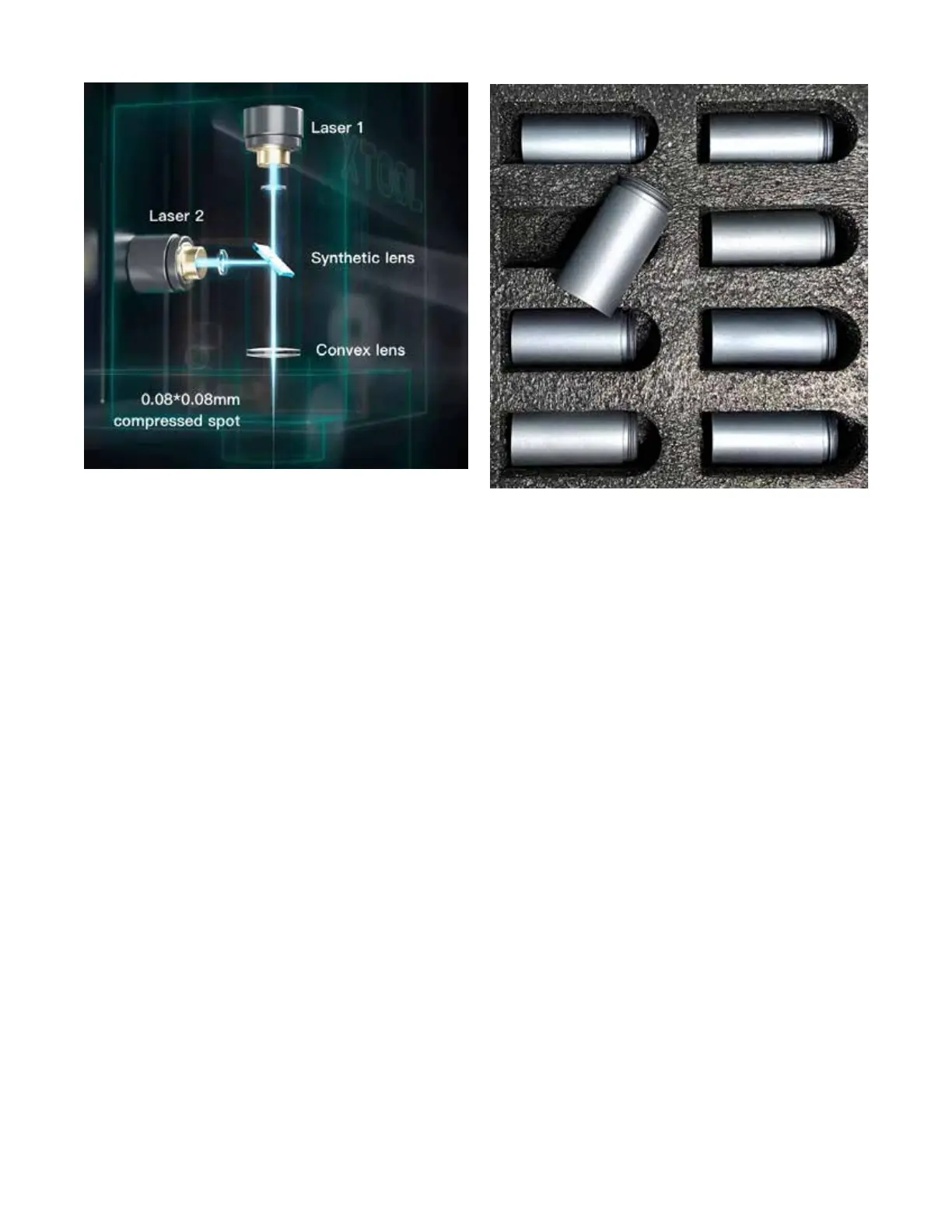

FIG. 4. e purchase of the xTool Rotary attachment includes this

set of extension legs that easily screw into the device’s built-in legs to

raise the unit.

as well as when USB or WiFi communication is interrupted.

During operation, the heat of the laser, reacting to the surface of

the workpiece, will produce, to varying degrees, noxious smoke,

soot, and other odors. Adequate ventilation, with the use of an

enclosure and exhaust fan, repositioning the laser device near a

window, or using fans to direct the airborne contaminants out

of the environment, should solve this issue.

Workflows. e xTool D1 is unique in that the user is provided

with three connection options: e standard USB cable con-

nection, WiFi, and offline, with the use of the provided TF

card. e TF card can contain only one job at a time. When a

new job is sent, it overwrites the current job. A job on a TF card

is processed by pressing the device button on the right front of

the machine frame. ese options mean the connection is not

limited to the length of an available USB cable.

e D1 has one of the most direct and simple workflows, as-

suming that the connection has already been made:

1. Position the workpiece

2. Adjust the focus.

3. In the software…

a. Select the connection mode

b. Select Engrave, Cut or both

c. Select the workpiece type

d. Position the laser head relative to the work-

piece

e. Press Start

Loading...

Loading...