© Copyright. Not to be reproduced without the permission of Xtrac Ltd.

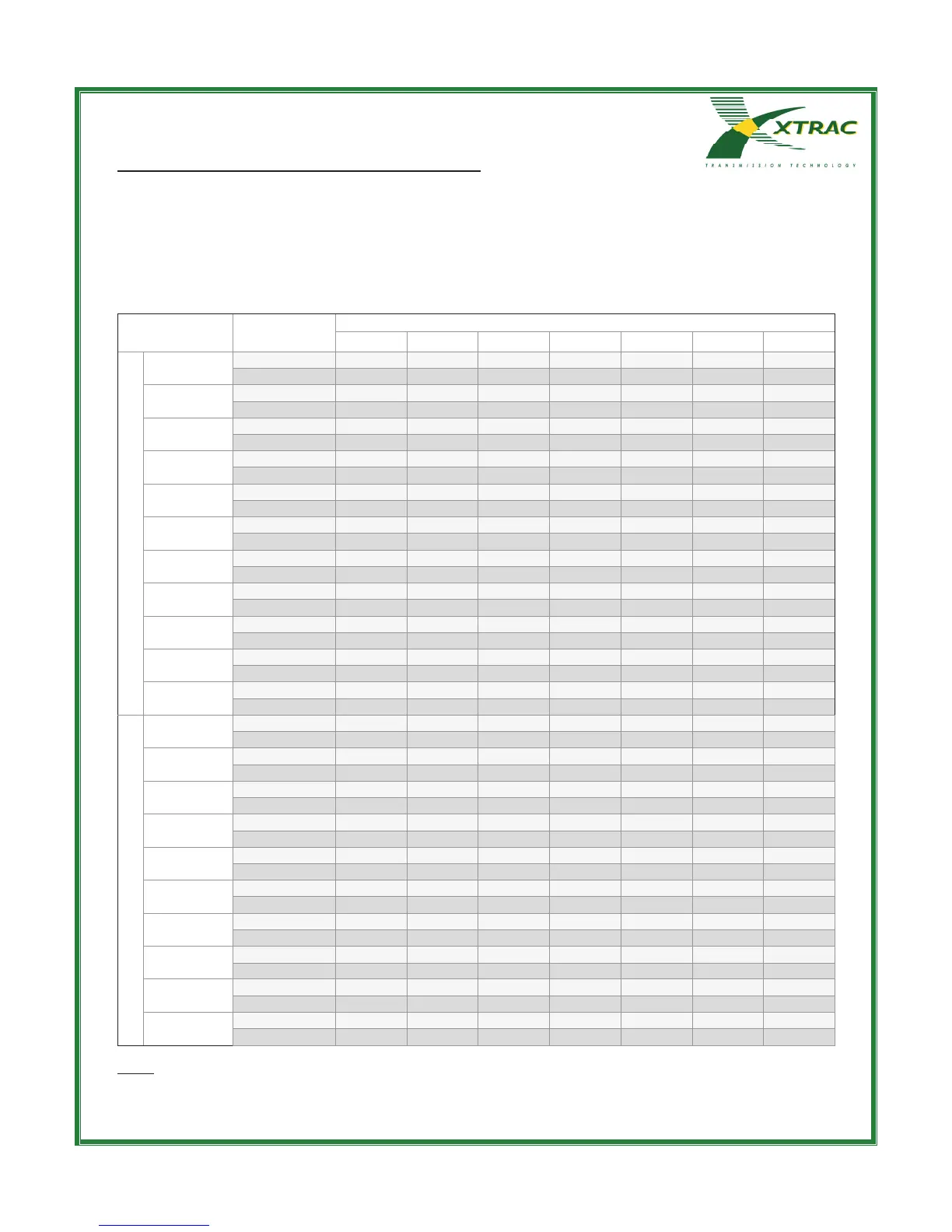

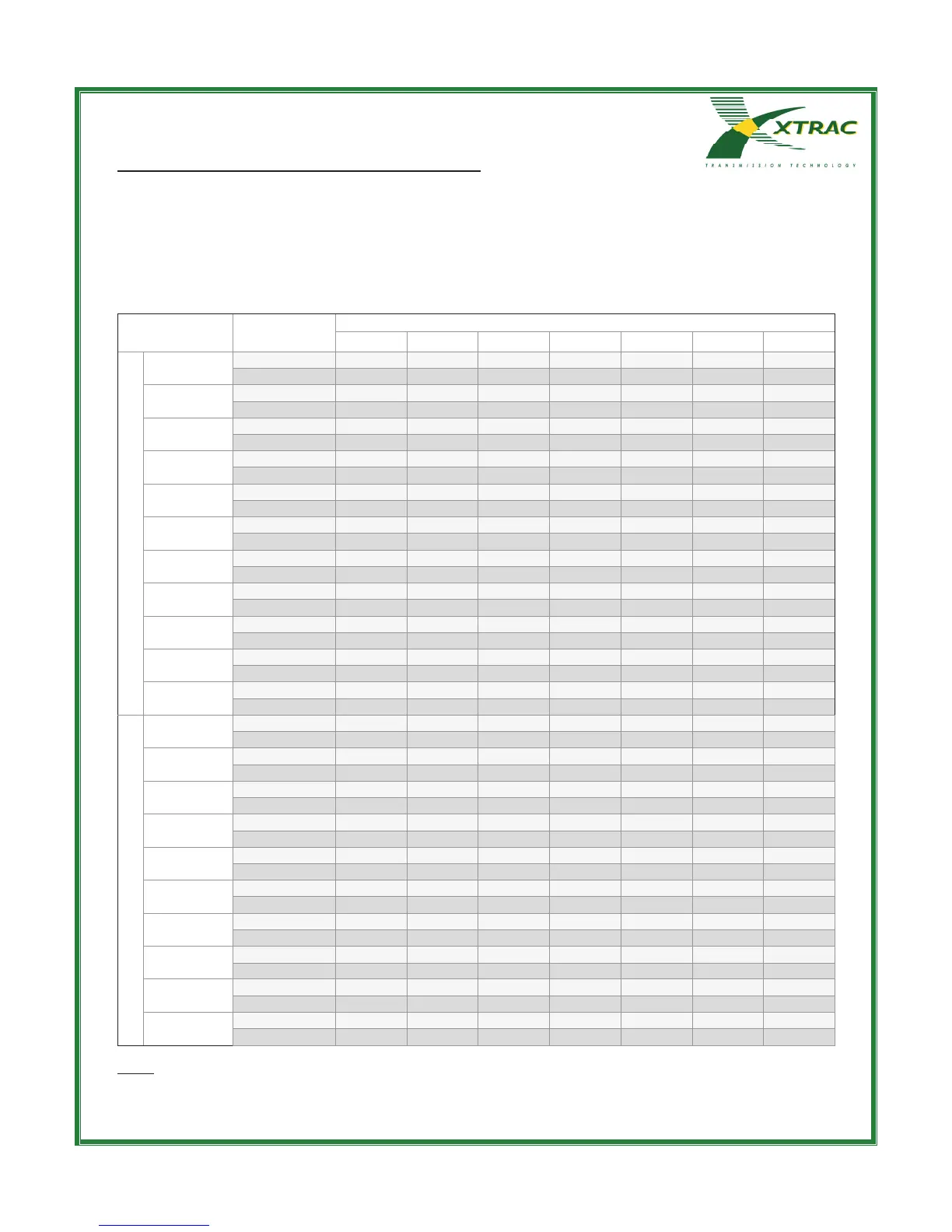

3. Length of engagement for mating threads

If failure of a threaded assembly should occur, it is preferable for the screw to break rather than have either the

external or internal thread strip. In other words, the length of engagement of mating threads should be sufficient to

carry the full load necessary to break the screw without the threads stripping.

Internal thread length in casings shall be as per XS008 (Imperial) and XS009 (Metric). The minimum length of

engagement for mating threads quoted in the table below are in mm. They were calculated based on the

Machinery's Handbook 26, page 1490 and 1491.

STUD

MATERIAL

INTERNAL THREAD MATERIAL

RZ5 L169 3.2384.6 2014T6 7075T6 Ti64 17-4PH

METRIC

M3x0.5

3S.145D 7.5 5.5 5.0 3.5 3.0 2.0 2.0

Ti64 6.0 4.0 4.0 2.5 2.5 2.0 2.0

M4x0.7

3S.145D 10.0 7.0 6.5 4.5 4.0 2.5 2.5

Ti64 7.5 5.5 5.0 3.5 3.0 2.5 2.5

M5x0.8

3S.145D 12.5 9.5 8.5 5.5 5.0 3.0 3.0

Ti64 9.5 7.0 6.5 4.5 3.5 3.0 3.0

M6x1.0

3S.145D 15.0 11.0 10.0 6.5 5.5 3.5 3.5

Ti64 11.5 8.5 7.5 5.0 4.5 3.5 3.5

M7x1.0

3S.145D 18.5 13.5 12.5 8.0 7.0 4.5 4.5

Ti64 14.0 10.0 9.5 6.0 5.5 4.5 4.5

M8x1.25

3S.145D 20.5 15.0 13.5 9.0 7.5 5.0 5.0

Ti64 15.5 11.0 10.5 7.0 6.0 5.0 5.0

M10x1.25

3S.145D 27.0 19.5 18.5 12.0 10.0 6.0 6.0

Ti64 20.5 15.0 14.0 9.0 7.5 6.0 6.0

M10x1.5

3S.145D 25.5 18.5 17.5 11.5 9.5 6.0 6.0

Ti64 19.5 14.0 13.0 8.5 7.5 6.0 6.0

M12x1.5

3S.145D 32.5 23.5 22.0 14.0 12.0 7.5 7.5

Ti64 24.5 18.0 16.5 10.5 9.0 7.5 7.5

M12x1.75

3S.145D 31.0 22.5 21.0 13.5 11.5 7.5 7.5

Ti64 23.5 17.0 16.0 10.5 9.0 7.5 7.5

M14x2.0

3S.145D 36.5 26.5 24.5 16.0 13.5 8.5 8.5

Ti64 27.5 20.0 18.5 12.0 10.0 8.5 8.5

IMPERIAL

1/4" UNF

3S.145D 16.5 12.0 11.0 7.5 6.0 4.0 4.0

Ti64 12.5 9.0 8.5 5.5 4.5 4.0 4.0

1/4" UNC

3S.145D 14.55 10.5 9.5 6.5 5.5 3.5 3.5

Ti64 11.0 8.0 7.5 5.0 4.0 3.5 3.5

5/16" UNF

3S.145D 21.0 15.5 14.0 9.0 8.0 5.0 5.0

Ti64 16.0 11.5 10.5 7.0 6.0 5.0 5.0

5/16" UNC

3S.145D 19.0 14.0 13.0 8.5 7.0 4.5 4.5

Ti64 14.5 10.5 9.5 6.5 5.5 4.5 4.5

3/8" UNF

3S.145D 26.5 19.0 18.0 11.5 10.0 6.0 6.0

Ti64 20.0 14.5 13.5 8.5 7.5 6.0 6.0

3/8" UNC

3S.145D 23.5 17.0 15.6 10.0 8.5 5.5 5.5

Ti64 17.5 13.0 12.0 7.5 6.5 5.5 5.5

7/16" UNF

3S.145D 30.5 22.0 20.5 13.5 11.5 7.0 7.0

Ti64 23.0 16.5 15.5 10.0 8.5 7.0 7.0

7/16" UNC

3S.145D 27.5 20.0 18.5 12.0 10.0 6.5 6.5

Ti64 20.5 15.0 14.0 9.0 7.5 6.5 6.5

1/2" UNF

3S.145D 36.0 26.0 24.5 15.5 13.5 8.0 8.0

Ti64 27.0 19.5 18.5 12.0 10.0 8.0 8.0

1/2" UNC

3S.145D 32.0 23.0 21.5 14.0 12.0 7. 5 7.5

Ti64 24.0 17.5 16.5 10.5 9.0 7.5 7.5

Note: If the length of thread engagement is less than that specified in the table above, then a reduced tightening

torque should be determined using Xtrac Program AE-5148, available from the intranet in Reference Document /

Verification Tools.

Loading...

Loading...