1-8

MOUNTING THE OUTBOARD

MOTOR

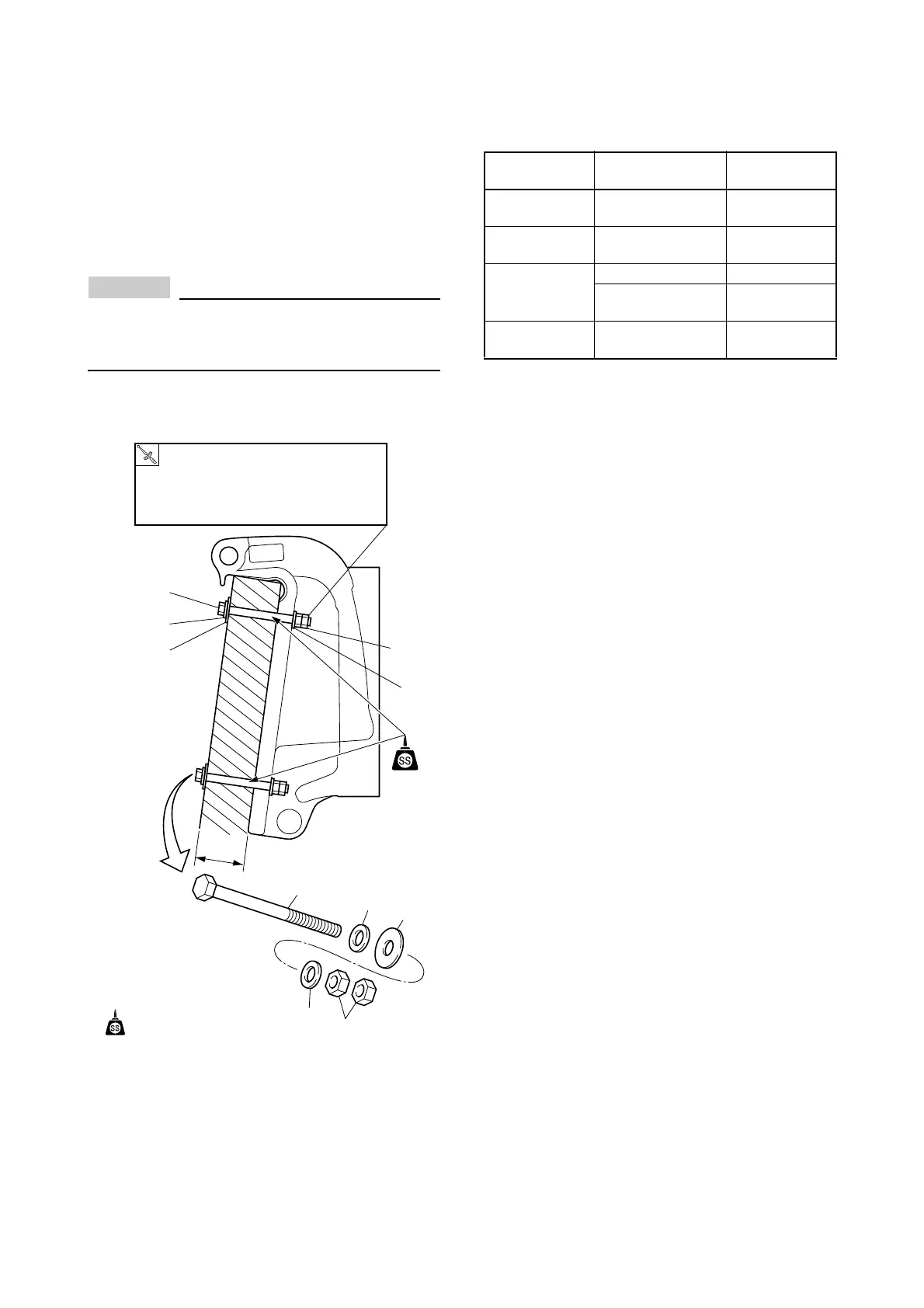

4. Apply sealant to the mount holes, and se-

cure the motor with supplied mount hard-

ware.

For tightening procedure, first tighten the in-

side nut, then the double nuts each other.

Make sure there is no clearance between

boat transom and motor clamp bracket.

Otherwise, the clamp bracket could break.

* The upper mount bolt is usually installed to

the 2nd hole from top.

* Tighten the mounting bolts/nuts to suitable torque

depending on the boat transom structure, mate-

rial, design, etc.

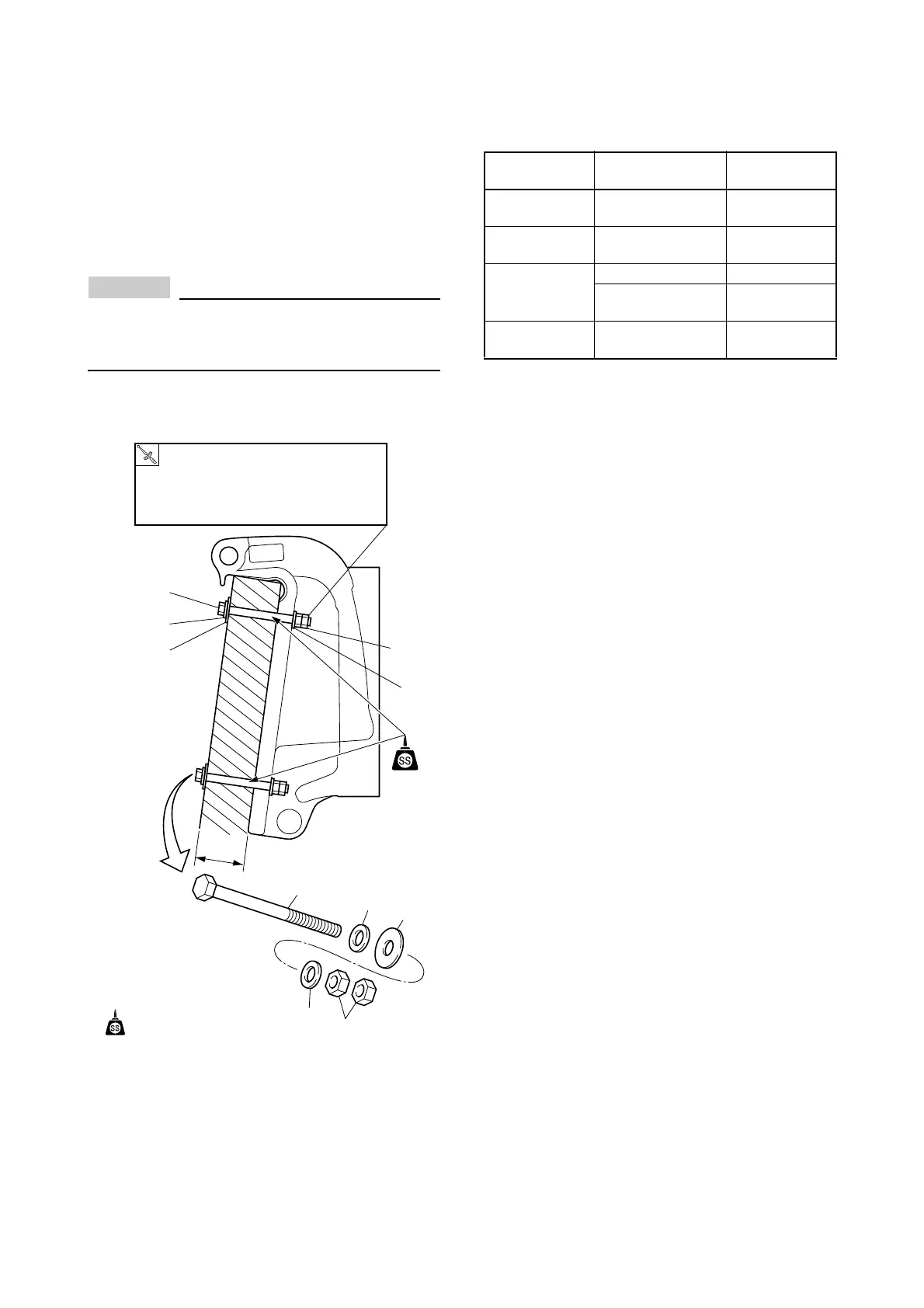

For above 115 (V4) and F75, select the tran-

som mount bolt depending on the boat tran-

som thickness.

* High tension bolt is recommended for F350.

(a)

For reference:

(a)

(b)

(b)

(d)

(d)

(b)

(b)

(c)

(c)

(a) Mounting bolt

(b) Small washer

(c) Large washer

(d) Nut

: Sealant

T

M8: 18 Nm, 1.8 kgf•m, 13 lb•ft

M10: 36 Nm, 3.6 kgf•m, 27 lb•ft

M12: 52 Nm, 5.2 kgf•m, 38 lb•ft

Boat transom

thickness (T)

Mount bolt size Bolt P/N

55 – 65 mm

(2.17 – 2.56 in.)

M12 ×115 mm 90101-12M03

65 – 75 mm

(2.56 – 2.95 in.)

M12 ×130 mm 90101-12M05

75 – 95 mm

(2.95 – 3.74 in.)

M12 ×150 mm 90101-12M77

M12 ×150 mm

[High tension bolt]

90101-12031

95 – 115 mm

(3.74 – 4.53 in.)

M12 ×170 mm

[High tension bolt]

90101-12036

Loading...

Loading...