8

DX200

■ DISASSEMBLY PROCEDURE

1.

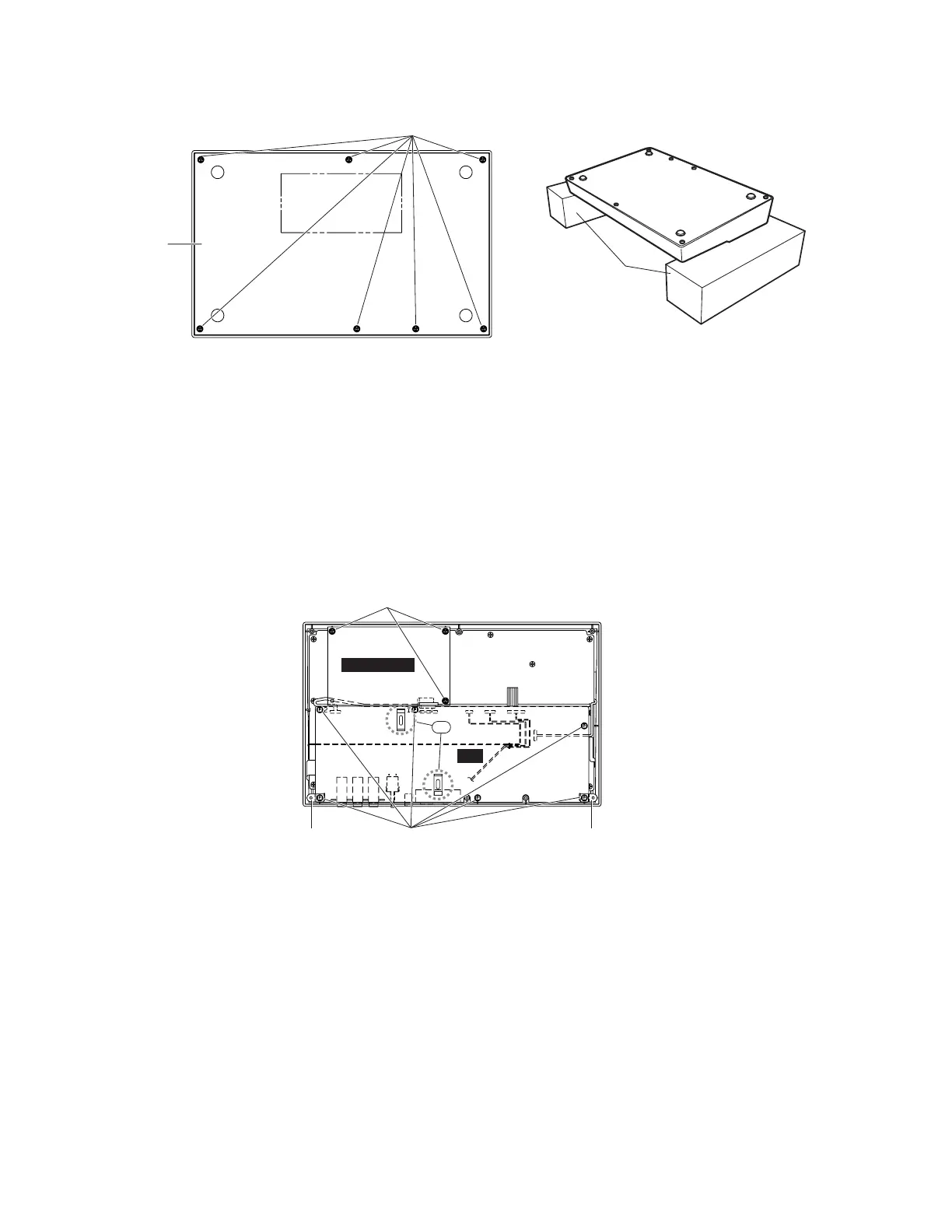

Bottom Assembly (time required: about 1 min)

1-1 Remove the seven (7) screws marked [180]. The

bottom assembly can then be removed. (Fig. 1)

* If you turn the mixer upside down for

disaasembling and assembling, put 2 wooden

bolsters underneath the unit at its both side ends to

protect PN sheet from being damaged. (Fig. 1-1)

[180]

Bottom Assembly

PLG150-DX

DM

[160]

[120][130] [140]

*1

*1

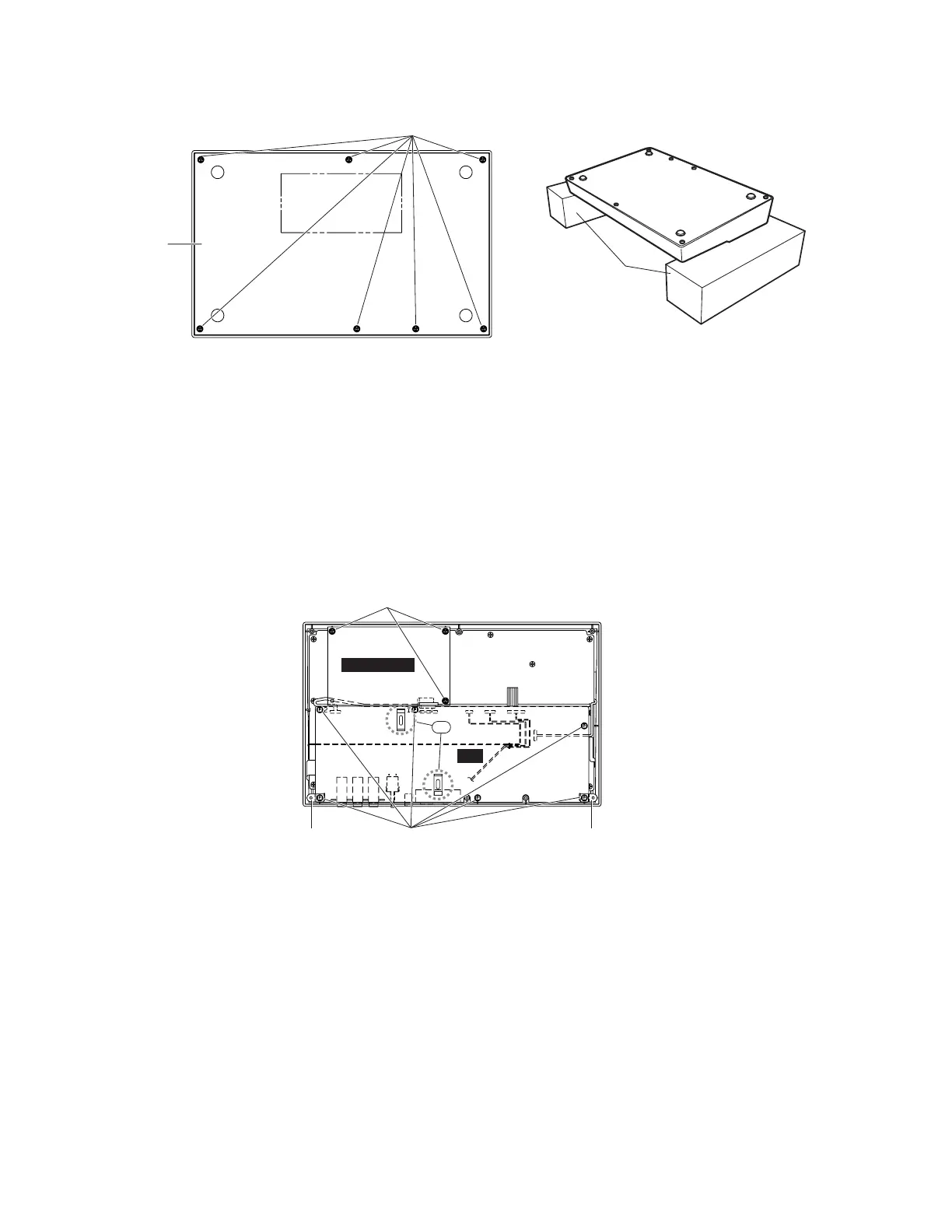

2. PLG150-DX Circuit Board

(time required: about 1 min)

2-1 Remove the bottom assembly. (See Procedure 1.)

2-1

Remove the tree (3) screws marked [160]. The PLG150-

DX circuit board can then be removed. (Fig. 2)

* Attachment consideration of the PLG150-DX

circuit board.

When installing the PLG150-DX circuit board, do

with connector assembly as shown in the fig 2-1.

Fit the PLG150-DX circuit board caring not to let

the connector assembly in it.

[180]: Bind Head Tapping Screw-B 3.0X6 MFZN2Y (EP600130)

[120]: Bind Head Tapping Screw-P 2.6X8 MFZN2Y (EP620100)

[130]: Angle, L (V655450)

[140]: Angle, R (V655460)

[160]: Bind Head Tapping Screw-B 3.0X86 MFZN2Y (EP620130)

(Fig. 1)

(Fig. 2)

(Fig. 1-1)

Wooden bolster

DX200

Bottom side

Loading...

Loading...