NOTES:

(I)

Check to see that there is .no looseness between the inner and outer laces of the

ball bearings and needle bearings. If this is

the case, or if they

emir

abnormal noises

when turned, or do not

turn smoothly, replace.

Particular care should be taken in

the case of needle bearings

ro

see rhar the rollers are

nor cracked or chipped.

11

12

13

14

P.

(2)

As for the gears, if there is any uneven wear, galling, or scoring, they should be

repaired to replaced.

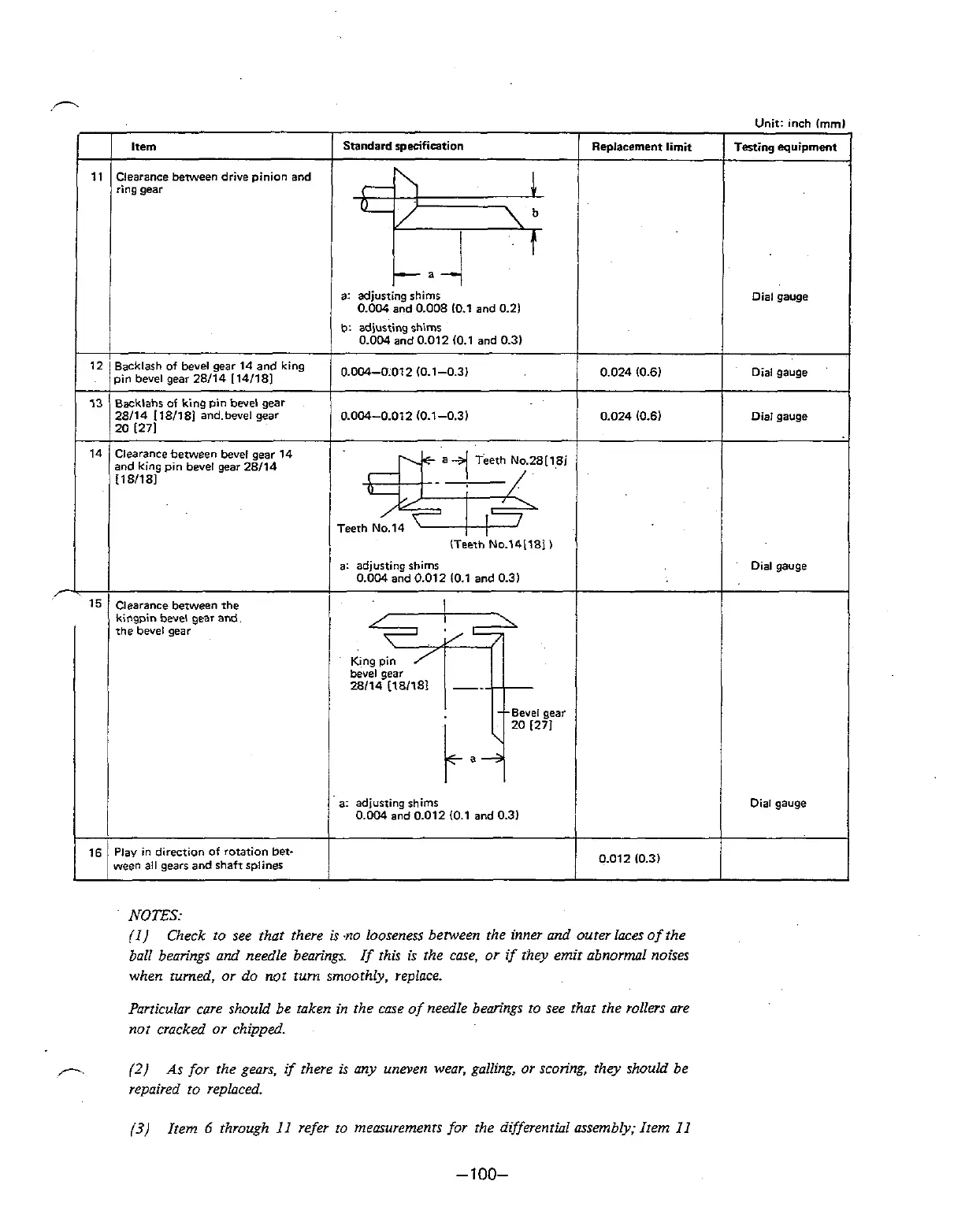

Item

Clearance between drive pinion and

ring gear

Backlash of bevel gear

14

and

king

pin bevel gear

28/14 114/18]

Backlahr

of

kingpin

bevel

gear

28/14 [18/181

andbevel gear

20 1271

Clearance between bevel gear

14

and king pin bevel

gear

28/14

Standard

specification

a: adjusting shims

0.004

and

0.008 10.1

and

0.21

b:

adjusting shims

0.004

and

0.012 (0.1

and

0.3)

0,004-0~012

(0.1-0.3)

0.004-0.012 10.1-0.3)

(3)

Irem

6

through

11

refer to measurements for the differential assembly; Irem

11

/--

Replacement limit

0.024 10.61

0.024 10.61

15

Unit: inch

(mml

Testing equipment

Dial gauge

Dial gauge

Dial gauge

16

I

.

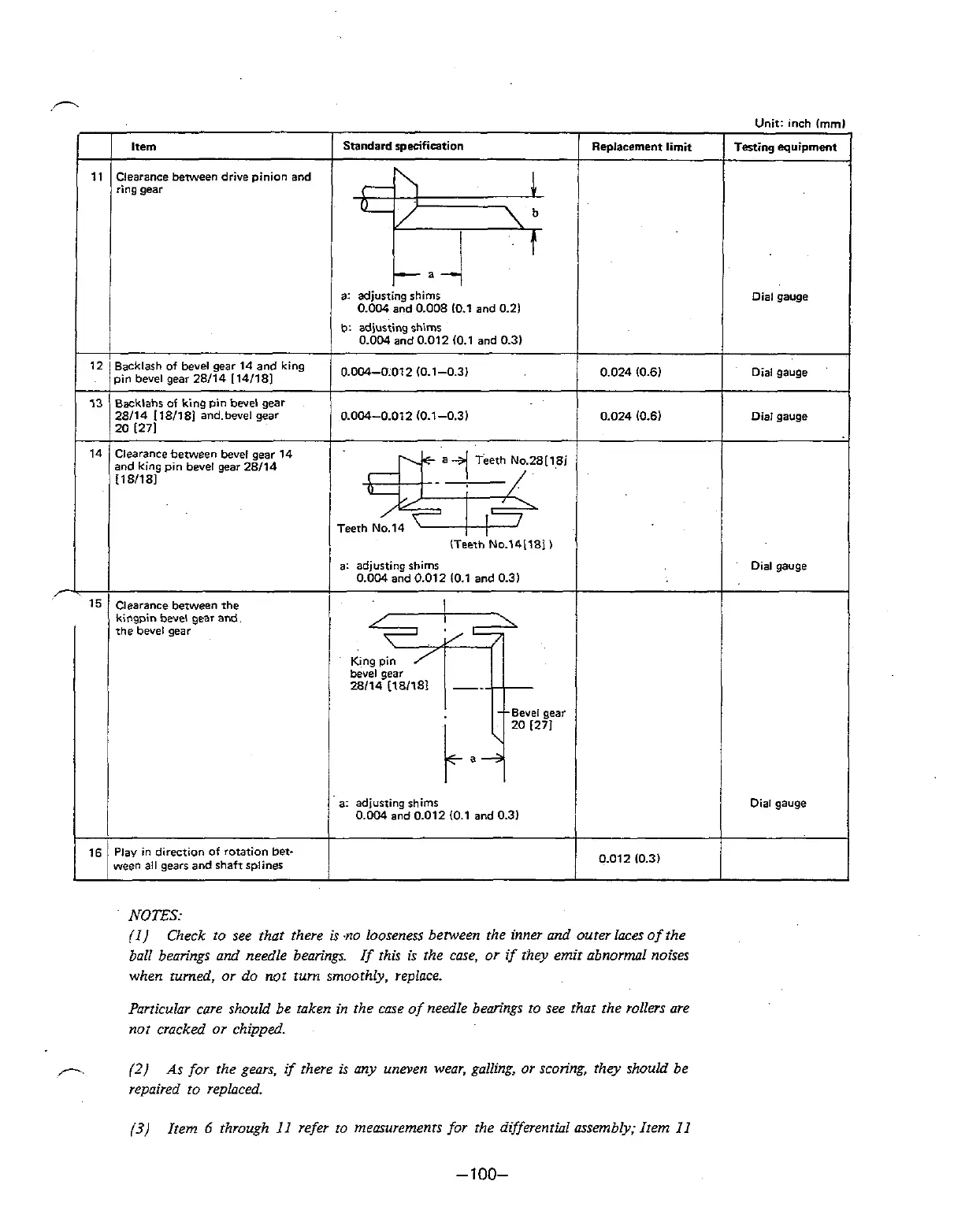

i;7[18j

118/181

Teerh

No.14

I

(Teeth

No.141181)

a:

adjusting shims

0.004

and

0.012 10.1

and

0.31

Clearance between the

Dial gauge

kingpin bevel gear

and

the bevel gear

Play in direction of rotation bet-

ween all gears and

shaft splines

0.012 10.3)

bevel gear

Bevel

gear

20 [271

a:

adjusting shims

0.004

and

0.012 (0.1

and

0.3)

Dial gauge

Loading...

Loading...