b) Brushes

-

..

.

Put the brushes in their respective brush

holder and measure the spring tension with

a spring balancer. Tension should be more

than 3.52 lbs (1.6 kg).

2) Length of Brushes

Standard brush length .is 0.630 in. (16

mm).

If any of them are worn out by more than

0.157 in. (4 mm), it should be replaced with

a

new one.

After replacing, check that the new brush

moves smoothly in the brush holder, and

that the end of the brush makes even con-

tact with the commutator surface. If the

contact is uneven, correct

it.

3) Brush Holder Continuity Test

,--.

Carry out

a

continuitytest between the in-

sulated brush holder and the ground.

There should be no continuity.

c) Armature

1)

Measuring Shaft Straightness

Place the shaft upon an end supporting

stand, and measure the straightness of the

shaft.

If

it

is

distorted by more than 0.0031 in.

(0.08 mm),

it

should be corrected.

2)

Commutator

If the surface

is

burnt or pitted,

it

should

be polished using

#500-+600 sandpaper.

If

it

is out-of-round by more than 0.0078 in.

(0.2 mm),

it

should be turned down on

a

lathe.

/-.

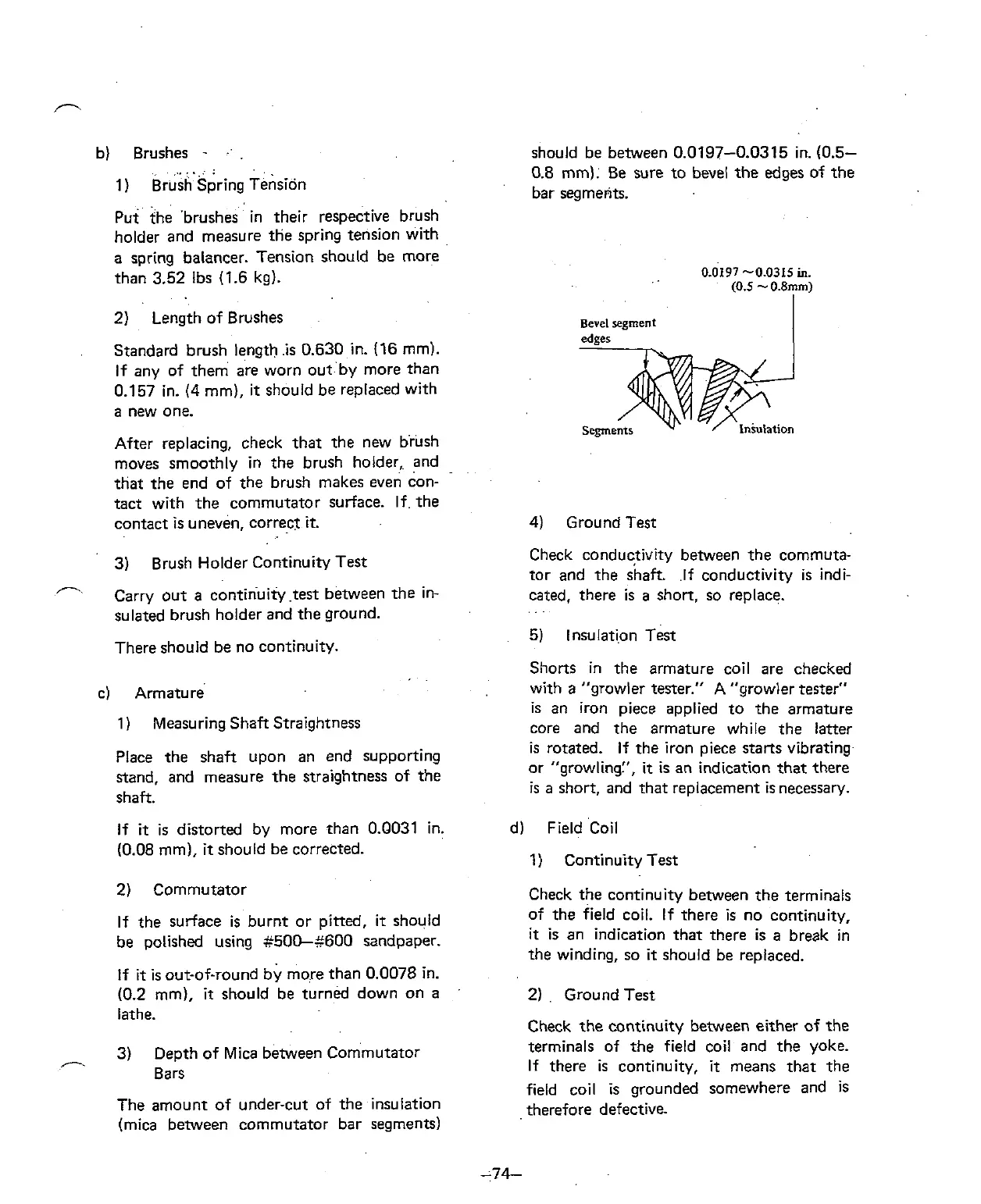

3)

Depth of Mica between Commutator

Bars

The amount of under-cut of the insulation

(mica between commutator bar segments)

should be between 0.0197-0.0315 in.

(0.5-

0.8 mm). Be sure to bevel the edges of the

bar segments.

0.0197 -0.0315

in.

(0.5

-

0.8mm)

I

Bevel

wment

I

4) Ground Test

Check conductivity between the commuta-

tor and the

&aft

If conductivity

is

indi-

cated, there

is

a

short, so replace.

. .

5)

Insulation Test

Shorts in the armature coil are checked

with

a

"growler tester." A "growler tester"

is

an iron piece applied to the armature

core and the armature while the latter

is

rotated. If the iron piece starts vibrating

or "growling!',

it

is

an indication that there

is

a

short, and that replacement

is

necessary.

d) Field Coil

1)

Continuity Test

Check the continuity between the terminals

of the field coil. If there

is

no continuity,

it

is

an indication that there

is

a

break in

the winding, so

it

should be replaced.

2)

.

Ground Test

Check the continuity between either of the

terminals of the field coil and the yoke.

If there

is

continuity,

it

means that the

field coil

is

grounded somewhere and

is

therefore defective.

Loading...

Loading...