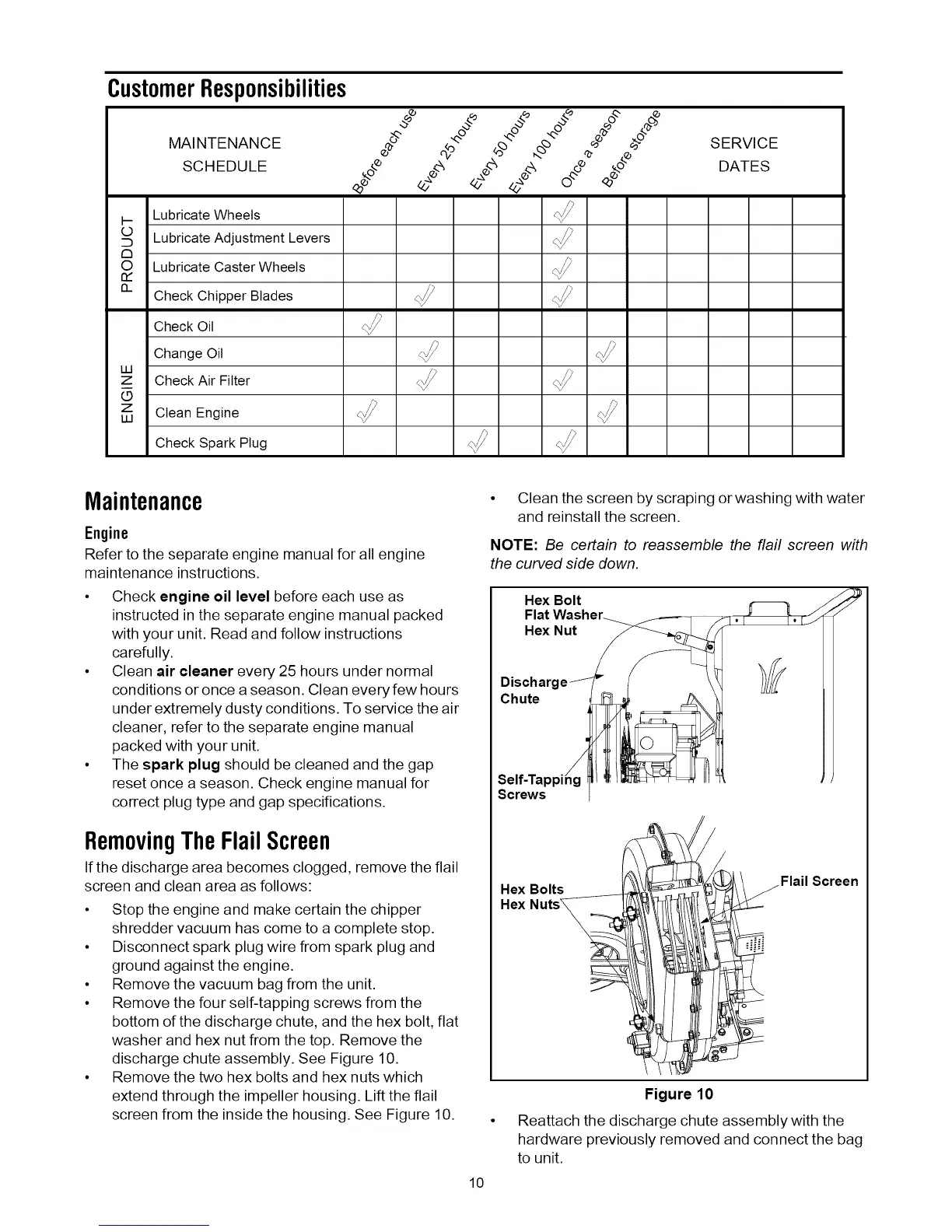

CustomerResponsibilities

MAINTENANCE

SCHEDULE

SERVICE

DATES

I-- Lubricate Wheels

Lubricate Adjustment Levers

n

O Lubricate Caster Wheels

Q_

CheckChipper Blades

CheckOil

ChangeOil

LU

z Check Air Filter

©

_ Clean Engine

Check Spark Plug

Maintenance

Engine

Refer to the separate engine manual for all engine

maintenance instructions.

• Check engine oil level before each use as

instructed in the separate engine manual packed

with your unit. Read and follow instructions

carefully.

• Clean air cleaner every 25 hours under normal

conditions or once a season. Clean every few hours

under extremely dusty conditions. To service the air

cleaner, refer to the separate engine manual

packed with your unit.

• The spark plugshould be cleaned and the gap

reset once a season. Check engine manual for

correct plug type and gap specifications.

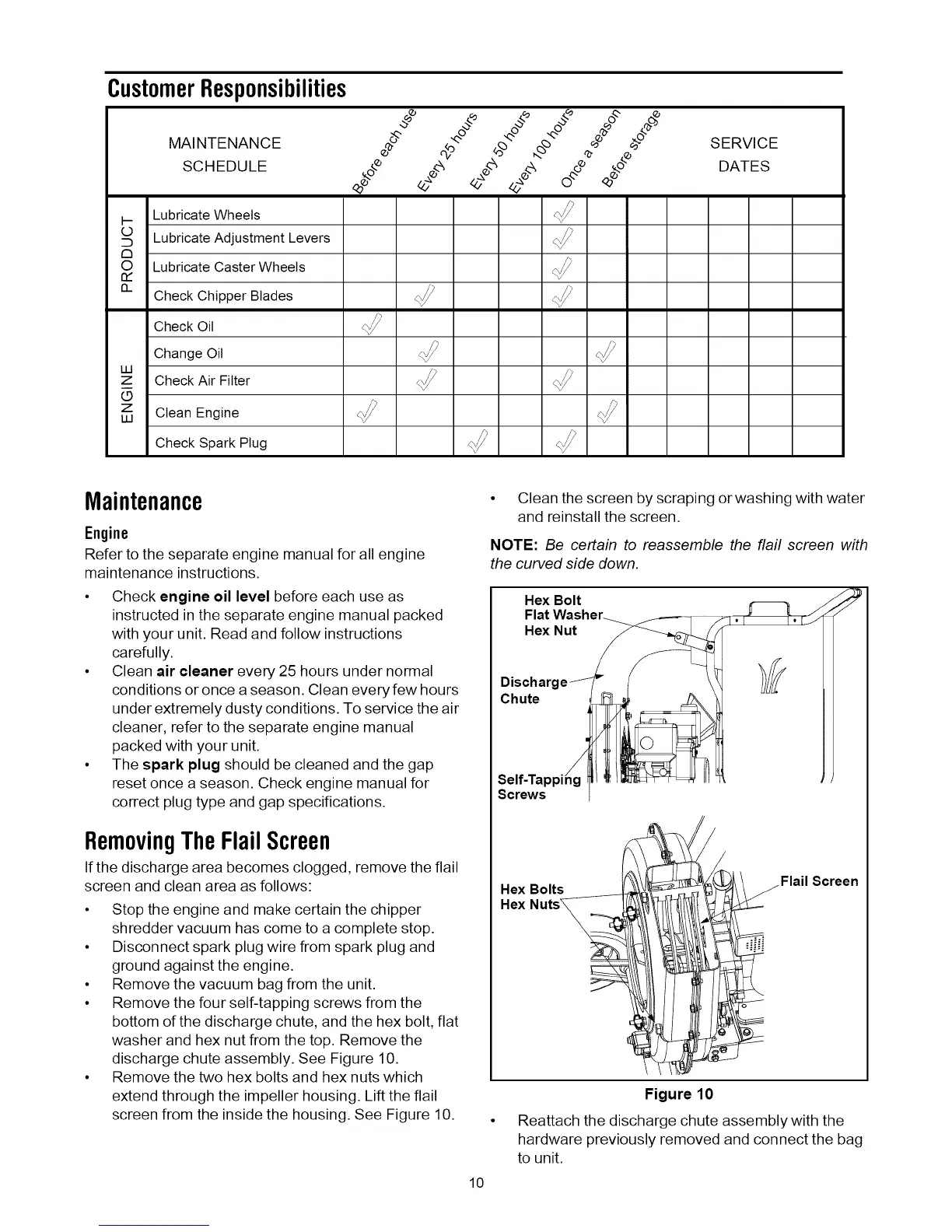

RemovingTheFlailScreen

If the discharge area becomes clogged, remove the flail

screen and clean area as follows:

• Stop the engine and make certain the chipper

shredder vacuum has come to a complete stop.

• Disconnect spark plug wire from spark plug and

ground against the engine.

• Remove the vacuum bag from the unit.

• Remove the four self-tapping screws from the

bottom of the discharge chute, and the hex bolt, flat

washer and hex nut from the top. Remove the

discharge chute assembly. See Figure 10.

• Remove the two hex bolts and hex nuts which

extend through the impeller housing. Lift the flail

screen from the inside the housing. See Figure 10.

10

• Clean the screen by scraping or washing with water

and reinstall the screen.

NOTE: Be certain to reassemble the flail screen with

the curved side down.

Hex Bolt

Flat

Hex Nut

Chute

Screws

Hex Bolts

Hex

Flail Screen

Figure 10

Reattach the discharge chute assembly with the

hardware previously removed and connect the bag

to unit.

Loading...

Loading...