MAINTENANCE

35

• Maintain the depth gauge at a clearance of .025" (.6 mm). Use a depth gauge tool for

checking the depth gauge clearances.

• Every time the chain is filed, check the depth gauge clearance.

• Use a flat file and a depth gauge jointer to lower all gauges uniformly. Use a .025" (.6 mm)

depth gauge jointer. After lowering each depth gauge, restore original shape by rounding the

front. Be careful not to damage adjoining drive links with the edge of the file.

• Depth gauges must be adjusted with the flat file in the same direction the adjoining cutter

was filed with the round file. Use care not to contact cutter face with flat file when adjusting

depth gauges.

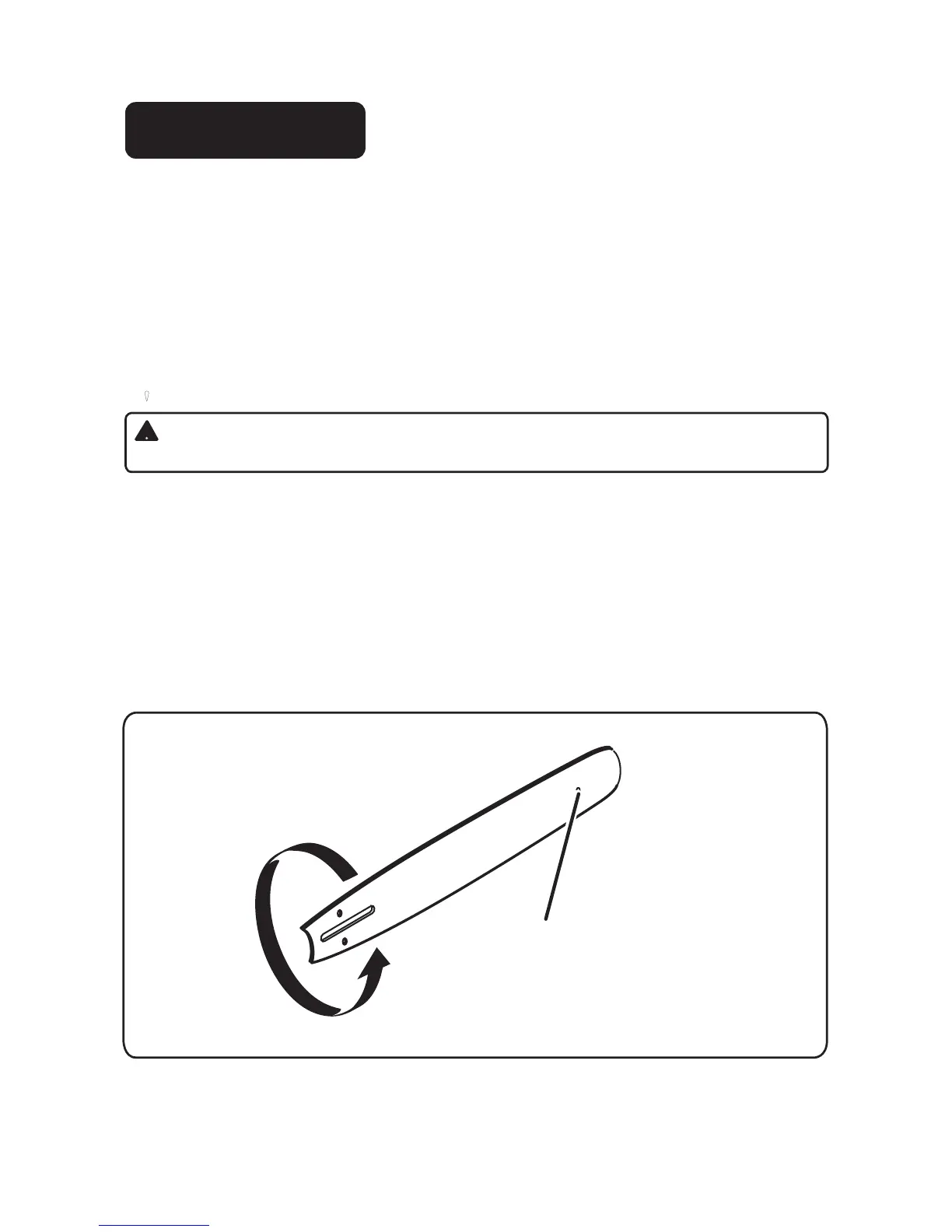

Every week of use, reverse the guide bar on the saw to distribute the wear for maximum bar

life. The bar should be cleaned every day of use, and checked for wear and damage.

Feathering or burring of the bar rails is a normal process of bar wear. Such faults should be

smoothed with a file as soon as they occur.A bar with any of the following faults should be

replaced:

• Wear inside the bar rails that permits the chain to lay over sideways

• Bent guide bar

• Cracked or broken rails

• Spread rails Lubricate guide bars weekly with a sprocket at their tip. Using a grease syringe,

lubricate weekly in the lubricating hole. Turn the guide bar and check that the lubrication holes

and chain groove are free of impurities.

MAINTAINING THE GUIDE BAR (See Figure 36)

MAINTAINING DEPTH GAUGE CLEARANCE

CAUTION:

Make sure the chain has stopped before you do any work on the saw.

Fig. 36

LUBRICATING HOLE

Loading...

Loading...