21

IM 12B06J03-02EN-P

3. INSTALLATION OF FU20

For optimum measurement results, the

FU20 should be installed in a location that

offers an acceptable representation of the

process composition and DOES NOT

exceed the specifications of the sensor.

threaded connections on both ends of the

sensor to allow installation in a wide

variety of applications.

3.1 Typical installation

The FU20 sensor is designed for versatile

in-line, immersion or off-line installation.

For best results the FU20 should be

mounted with the process flow coming

towards the sensor.

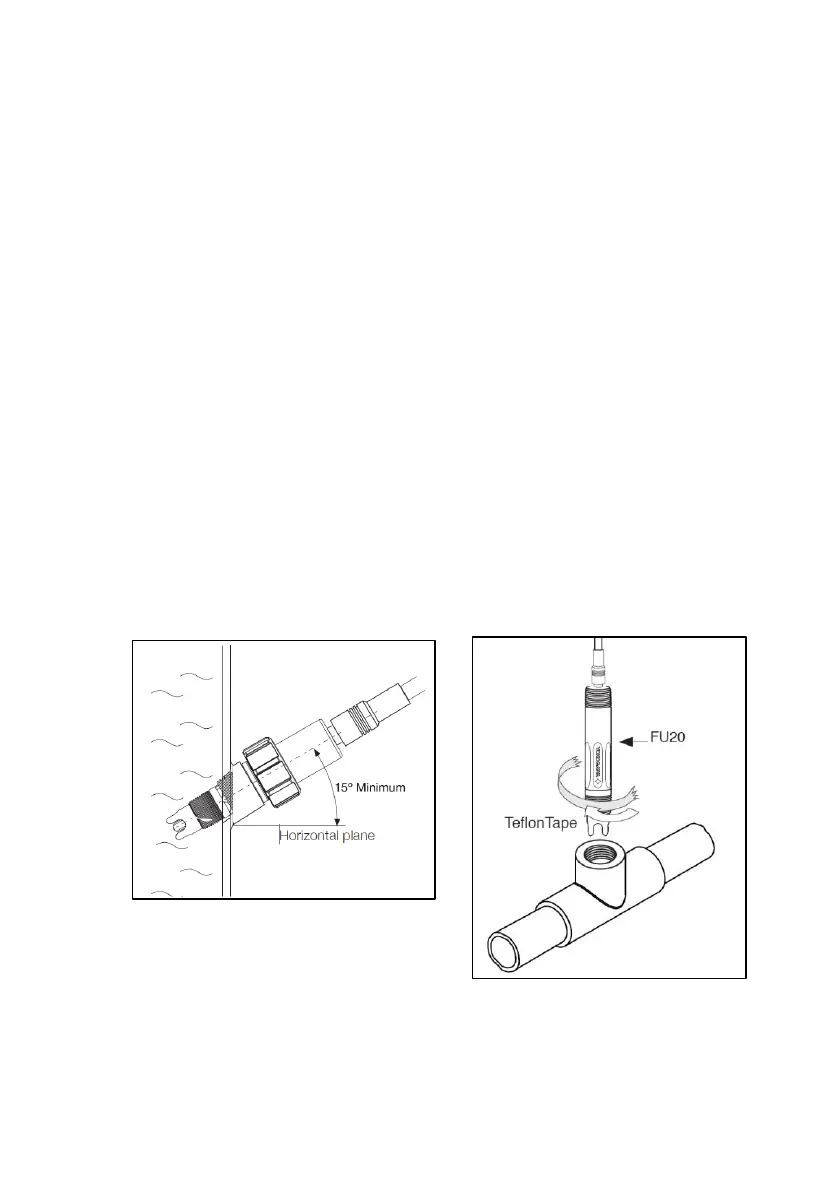

For the Fixed cable versions requires

installation of the sensor positioned at

least 15° above the horizontal plane to

eliminate air bubbles in the pH glass bulb

(see Figure 3).

The models type VP and VS can be

mounted in all angles with respect to the

horizontal plane including Upside Down.

Figure 3: Sensor installation

3.2 Preparing the sensor for use

Remove the sensor from its shipping box

and slide of the so-

tube filled with solution to prevent drying

out of the measuring elements during

shipment or storage. Although on the

Quality Inspection Certificate (QIC) all

factory calibration data is stored, it is

recommended to calibrate the sensor

before first use. A general calibration

procedure is described in Section 6 of this

Instruction Manual.

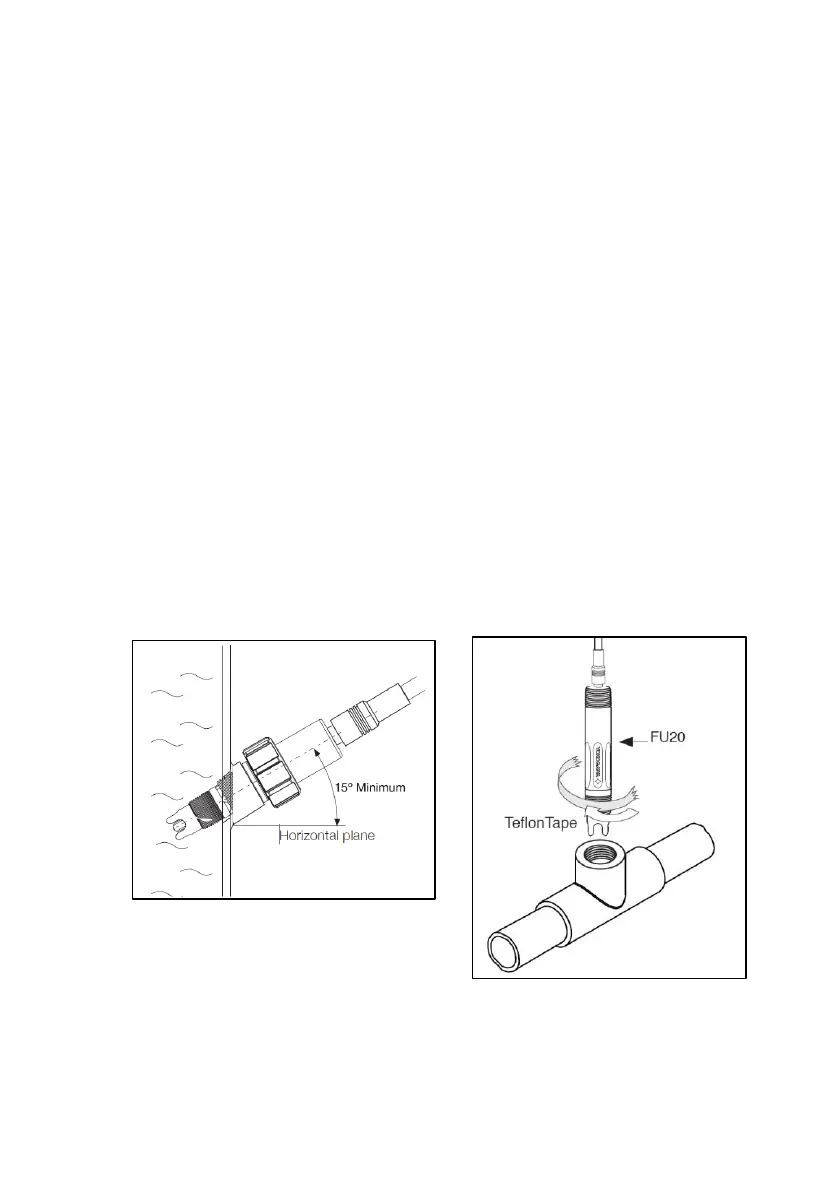

3.3 Mounting the sensor

The simplest mounting is to use one of

sensor. Apply Teflon tape to the

appropriate threaded end, then install the

sensor in the process Tighten the sensor

using a wrench on the sensor flats. (see

Figure 4).

Note: Do not overtighten the sensor

body. Max. torque applicable in paragraph

2.9

Figure 4: Simple mounting of sensor

Loading...

Loading...