16

P01432Q-rev.1

6. RefrigerantPipingWork

Table 6.1 Piping Size

inch (mm)

Model Gas Piping Liquid Piping

(H,Y)IDH072B21S 3/4 (19.05)

3/8 (9.52)

(H,Y)IDH096B21S 7/8 (22.2)

(3) Prepare eld-supplied copper pipes.

(4) Select clean copper pipes. Make sure there is no dust and moisture inside.

(5) The refrigerant oil for the refrigerant R410A is susceptible to moisture, an oxide lm, and fatty oil. Take

special care during the installation so that moisture, contaminations or old refrigerant oil will not enter

the refrigerant cycle. Otherwise, impurities may adhere to the expansion valve and it may prevent

proper operation.

(6) When cutting the pipes, use a pipe cutter to avoid grind swarf generation for the pipe cutting work. Blow

the inside of pipes with nitrogen or dry air to remove any dust or foreign materials before connecting

pipes. Do not use any tools which produce a lot of swarf such as a saw or a grinder.

6.1 Piping Materials

(1) The tolerance of refrigerant piping length differs depending on the combination with the outdoor unit.

Refer to “Installation and Maintenance Manual” of the outdoor unit for details.

(2) Select the piping size from the following table.

For details on refrigerant piping work, vacuum pump, and refrigerant charge, refer to the "Installation and

Maintenance Manual" for the outdoor unit.

Usethespeciednon-ammablerefrigerant(R410A)totheoutdoorunitintherefrigerantcycle.

DonotchargetheunitwithmaterialsotherthanR410A,suchashydrocarbonrefrigerants(propane

andisobutan),oxygen,ammablegases(acetylene,ammonia,etc.)orpoisonousgaseswhen

installing,maintainingandmovingtheunit.Theseammablesareextremelydangerousandmay

causeexplosion,are,orinjury.

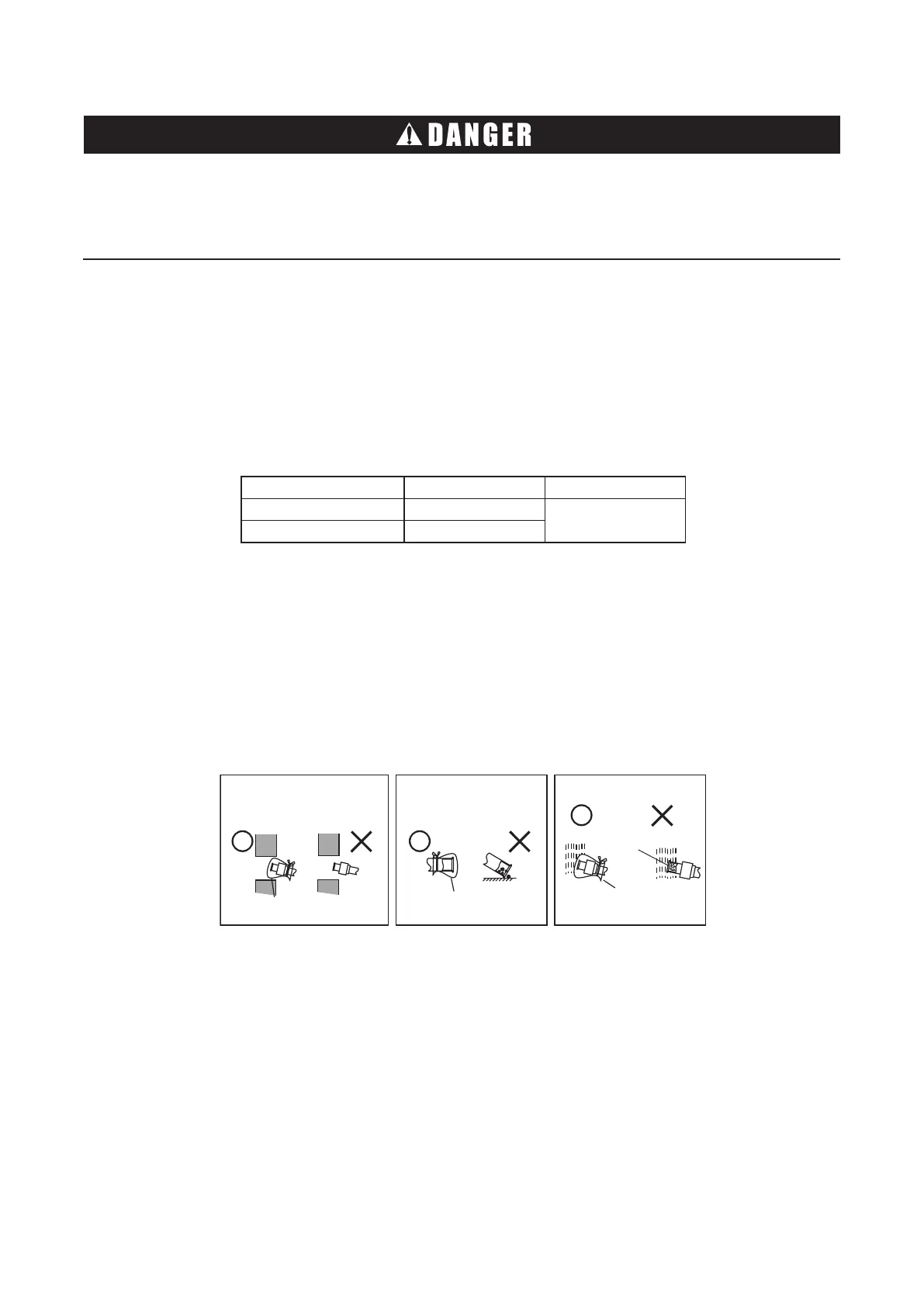

In Case of Getting the Pipe

Through a Hole in the Wall

Correct

CorrectIncorrect Incorrect

Correct Incorrect

HoleHole

Attach a cap or put a plastic bag

over the pipe end.

Attach a cap or put a plastic

bag over the pipe end.

Attach a cap or put a plastic

bag over the pipe end.

Rubber Band

Do not lay the pipe

directly on the ground.

Rain water

can come in.

Loading...

Loading...