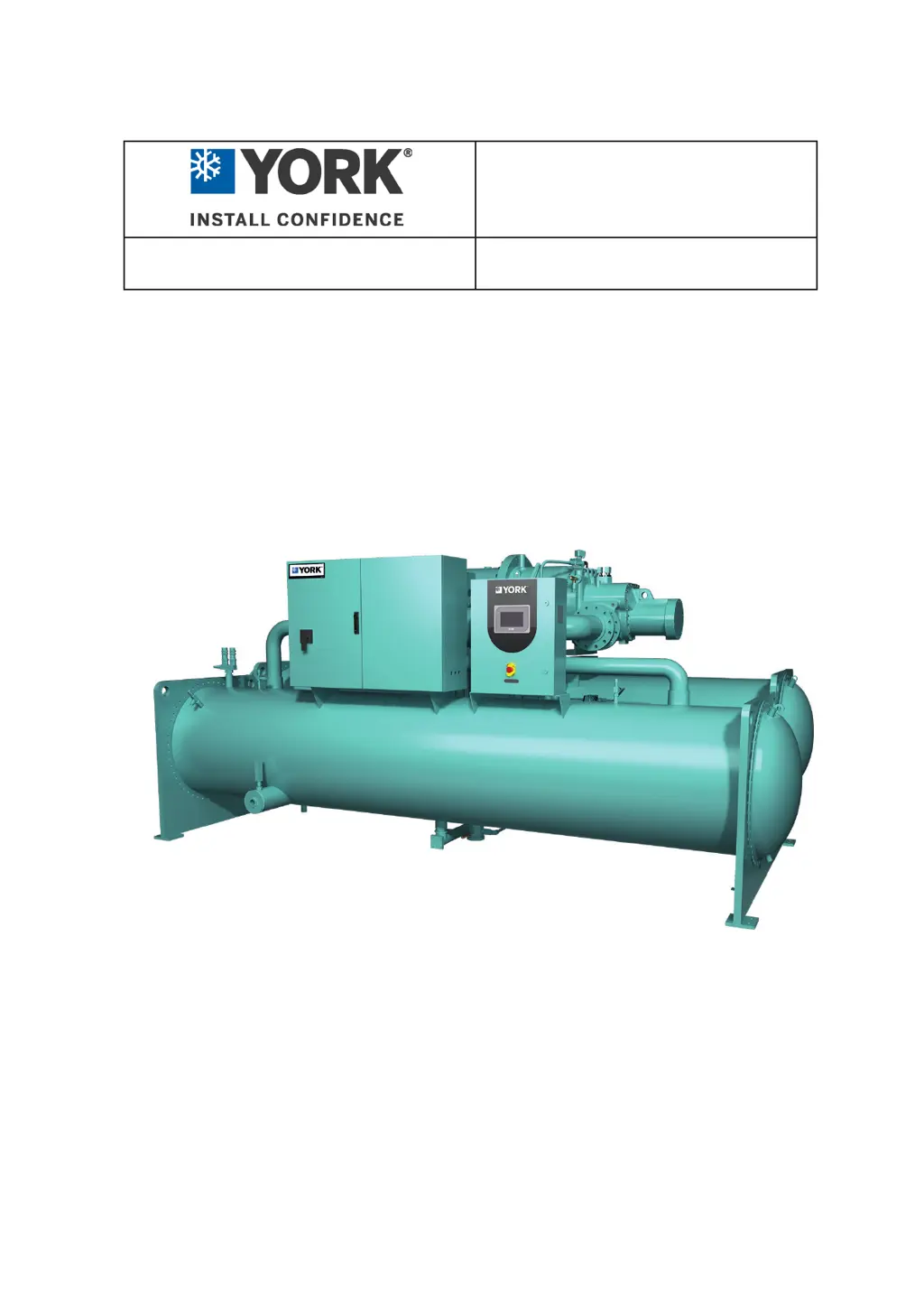

How to troubleshoot low evaporator pressure in a York YGWH 115?

- CctateAug 5, 2025

Low evaporator pressure in a York Chiller can be caused by several factors. The transducer might be reading incorrectly, so check it against a gauge. A defective chilled water temperature sensor, insufficient refrigerant charge (check for leaks and charge refrigerant into system), or low evaporator water flow (check flow) could also be responsible. Other potential causes include a liquid line filter clog (check liquid line filter), a defective feed or flow valve (repair or replace valve or control), dirty or restricted evaporator tubes (clean evaporator tubes), EEV failure or failure to open (check EEV or EEV drive), or insufficient load for system capacity (check low water temperature cutout setting and low evaporator pressure cutout setting).