Charter two Main installing requirements

Installation of the crankshaft

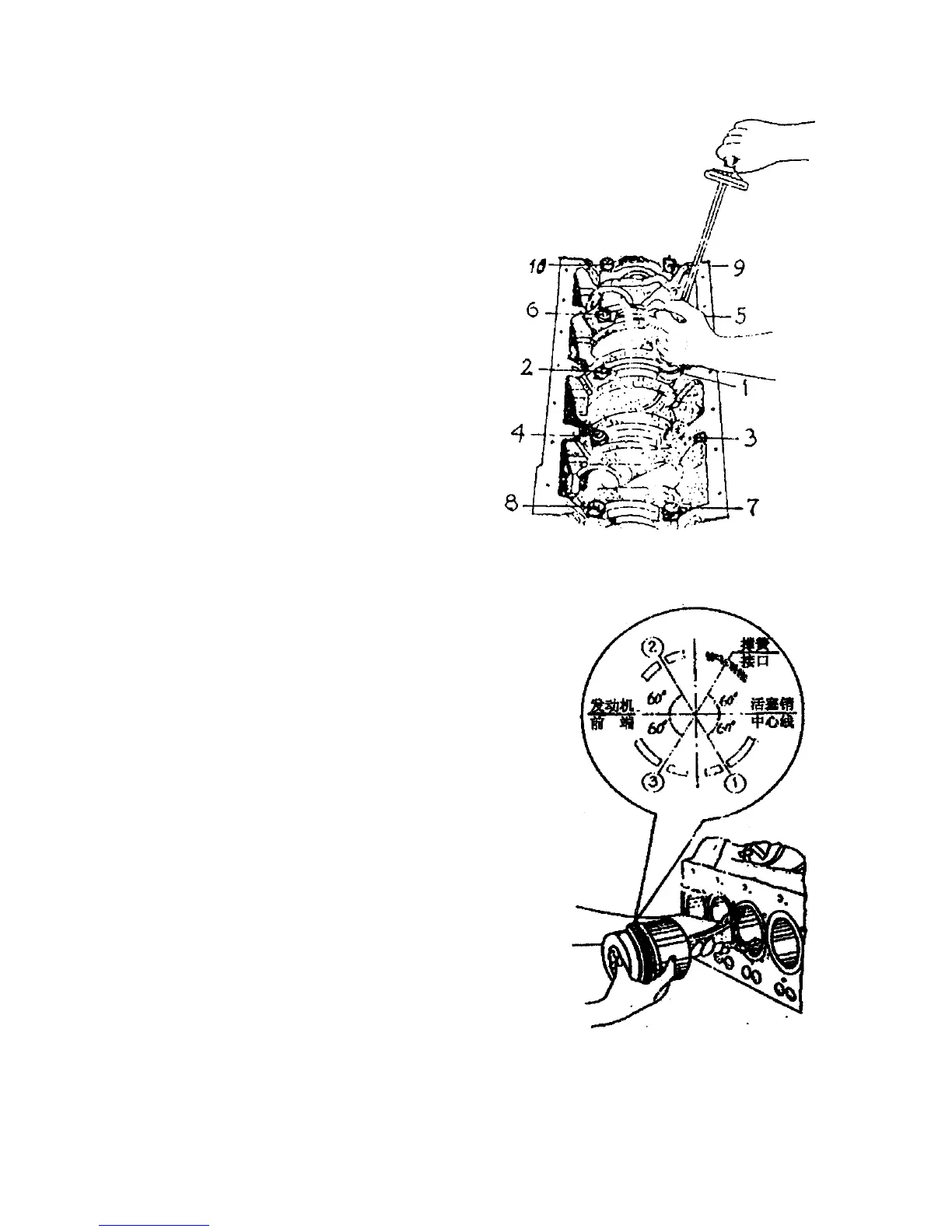

Figure 1 Tightening order of the main bearings

During crankshaft installation, the main

bearing bolts should be tightened from thrust

gear (the third gear) to both ends in order, and

in three steps: First, tighten to 60~80N.m;

Then, tighten to 160~180N.m;

Finally, tighten to 220~260N.m.

During every time, the crankshaft should be

rotated to check the mobility. It should be able

to rotate freely after the final tightening. The

axial clearance should be between 0.1 and

0.27mm.

Installations of the piston and the connecting rod

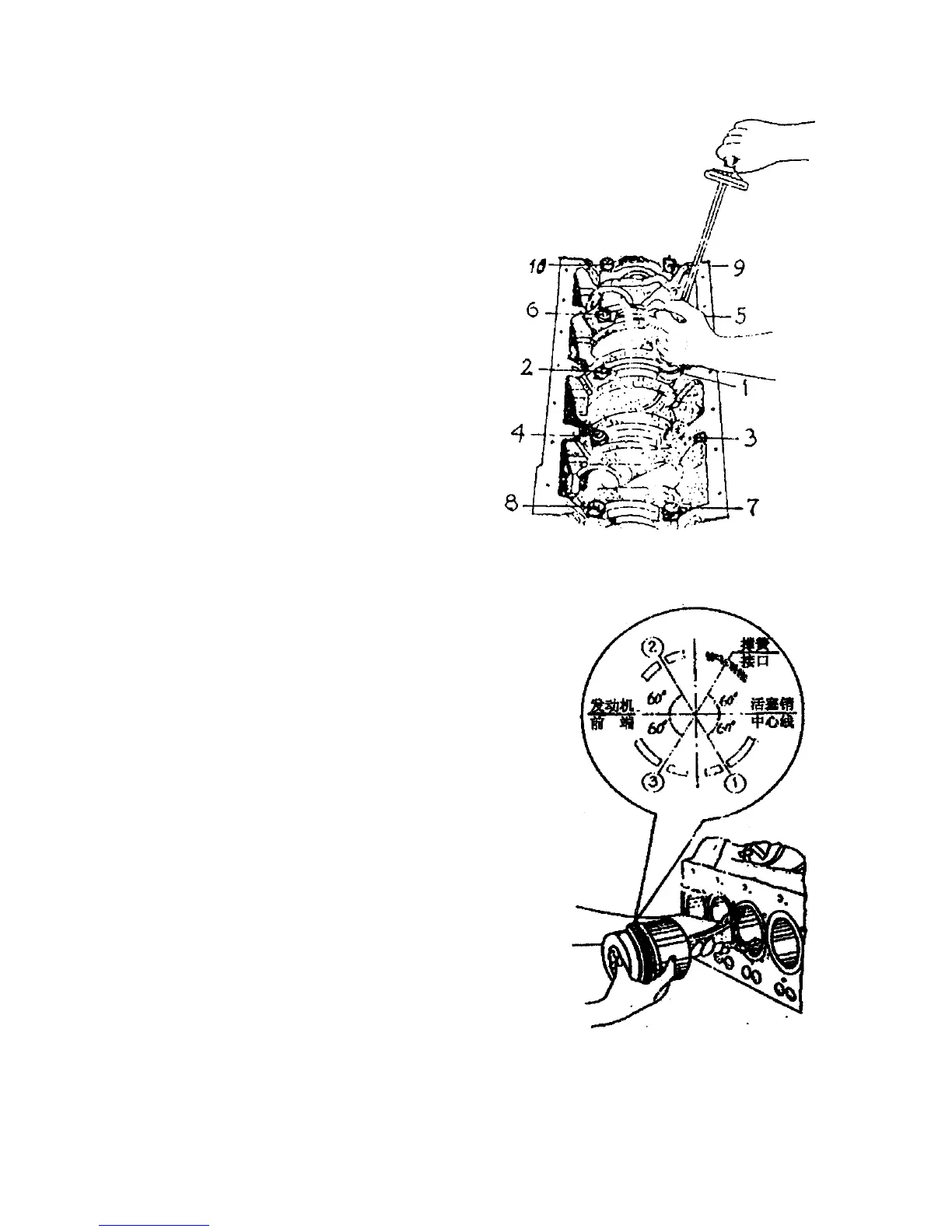

Figure 2 Orientation of the gap of piston rings

When installing the piston rings, put the surfaces

marked upward (the second positive twist ring inner

fillet upward). During positioning the piston-connecting

rod assembly into the cylinder bore, stagger the joints

in turn as shown in Figure 2, and put the arrow marked

on the top surface of piston towards the front end of

the engine. Remember spreading some clean oil before

tightening connecting-rod bolts. The tightening torque

should be between 160~200N.m, and completed in

three steps:

First, tighten to 50~70N.m;

Then, tighten to 100~120N.m;

Finally, tighten to 160~200N.m.

Loading...

Loading...