Page 8 Function-Decoders MX681, MX685, MX686, MX687, MX688

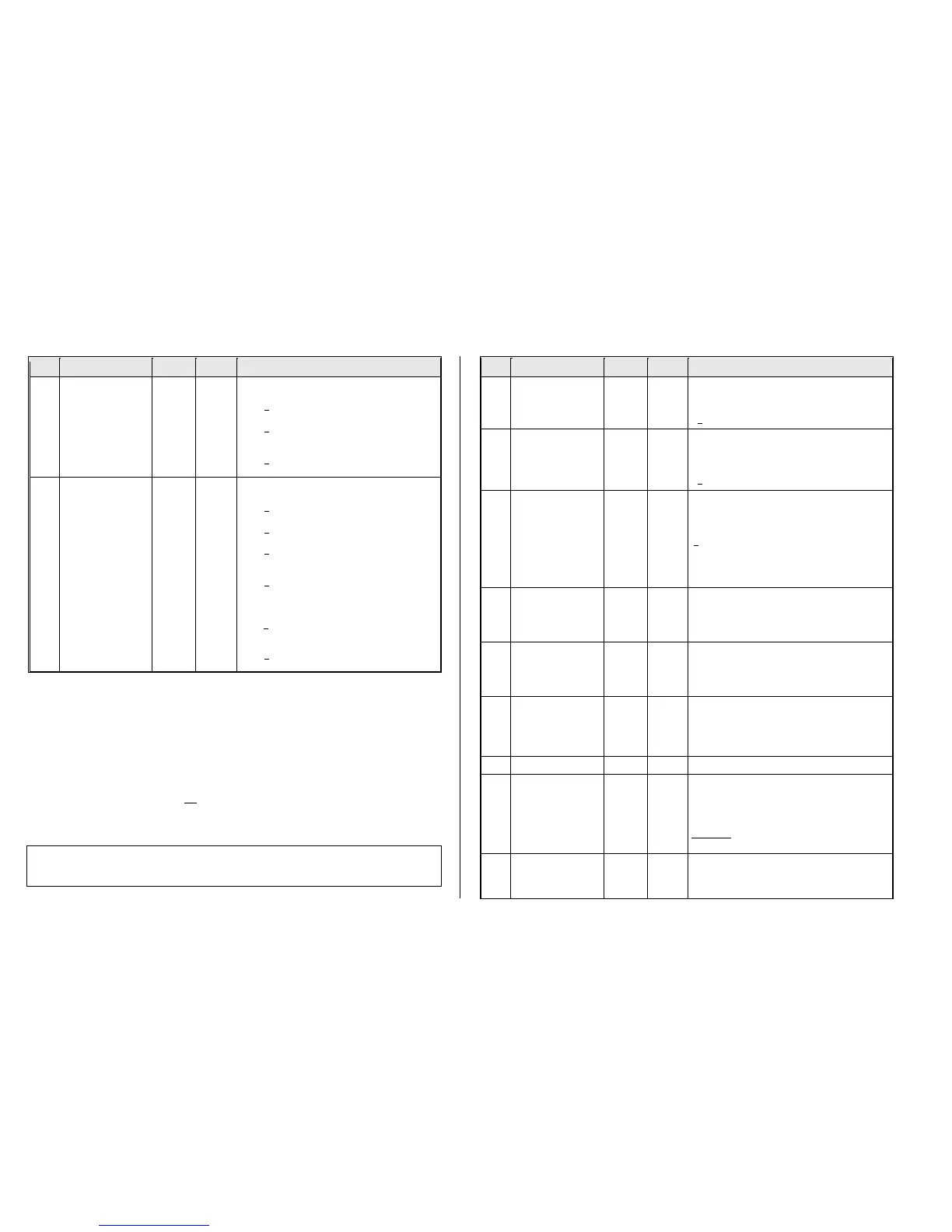

Alternate Mode

Function Status

F1- F8

Select the functions that should be ON during analog

operation.

Bit 0 = 0: F1 OFF in analog mode

= 1: …ON…

Bit 1 = 0: F2 OFF in analog mode

= 1: …ON…

………. F3, F4, F5, F6, F7

Bit 7 = 0: F8 OFF in analog mode

= 1: …ON…

Alternate Mode

Function. Status

F0, F9-F12

and

acceleration,

deceleration and motor

control in analog

67,

that is

Bit

0, 1, 6 = 1

Select the functions that should be ON during analog

operation.

Bit 0 = 0: F0 (forward) OFF in analog mode

= 1: …ON…

Bit 1 = 0: F0 (reverse) OFF in analog mode

= 1: …ON…

Bit 2 = 0: F9 OFF in analog mode

= 1: …ON…

………. F10, F11

Bit 5 = 0: F12 OFF in analog mode

= 1: …ON…

Bit 6 = 0: Analog operation with momentum as per

CVs #3 + 4; often needed for sound

= 1: Analog operation without momentum from

CVs #3 + 4; immediate response to track

voltage similar to classic analog control.

Bit 7 = 0: Analog operation without motor regulation.

= 1: Analog operation with motor regulation.

3.7 “Virtual” motor control and momentum

Even though function decoders don’t have an actual motor output, they can still be programmed with pa-

rameters for “virtual motor control”, in order to synchronize the actions of the function decoder with the

loco decoder, provided the first or second address of the function decoder is identical with the loco de-

coders. This is especially important during acceleration or deceleration, for example, when activating the

direction key without first stopping the train. It makes sense to use the same settings in these CV's as are

used in the locomotive decoder.

However, the 28-speed point curve is not available, only the three-point curve, because the relevant CV

numbers are used for the second address. For this reason, Bit 4 in CV #29 is also not available. And of

course, CV settings that relate to motor feedback are unnecessary.

For many applications though, the motor control CVs are not important

in function decoders. Setting CV #3 and #4 to match the CVs

of the loco decoder is sufficient.

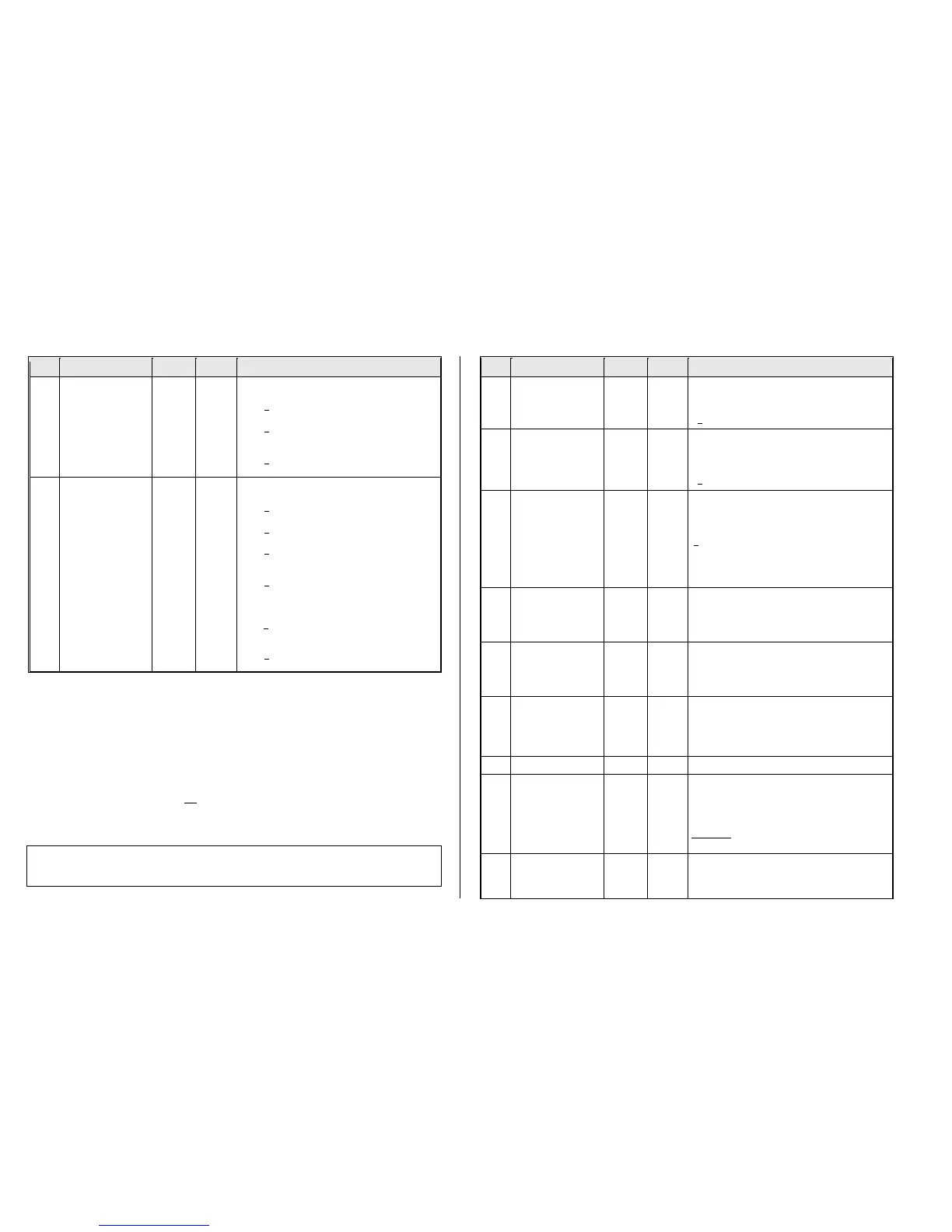

Internal speed step (1 … 255) applied as

lowest external speed step (= speed step 1)

(applies to 14, 28, or 128 speed step modes)

= 1: lowest possible speed

Internal speed step (1 … 255) applied as

highest external speed step

(14, 25 or 128, depending on the speed step mode

selected in CV # 29, Bit 1)

= 1 (same as 255): fastest speed possible.

1,

¼ to ½

of the

value in

CV #5

Internal speed step (1 … 255) applied as

medium external speed step (that is, speed step 7,

14 or 63 depending on the speed step mode selected

in CV #29, Bit 1)

”1" = default curve (Medium speed is set to one third of

top speed, i.e., if CV #5 = 255 the curve is the same as

if CV #6 would be programmed to 85)

The speed curve resulting from CV #2, 5 and 6 is auto-

matically smoothed out to prevent kinks.

The value multiplied by 0.9 equals acceleration time in

seconds from stop to full speed.

The effective default value for sound decoders is usual-

ly not the value given here, but is determined by the

loaded sound project.

The value multiplied by 0.9 equals deceleration time in

seconds from full speed to a complete stop.

The effective default value for sound decoders is usual-

ly not the value given here, but is determined by the

loaded sound project.

To temporarily increases the acceleration rate to a new

load or when used in a consist.

Bit 0-6: entered value increases or decreases

acceleration time in CV #3.

Bit 7 = 0: adds above value to CV #3.

= 1: subtracts above value from CV #3.

As above, but for deceleration and therefore CV #4.

Acceleration time (momentum) can be stretched in the

lower speed range:

Tens digit: Percentage of speed range to be

included (0 to 90%).

Ones digit: Exponential curve (0 to 9).

EXAMPLE:

CV #121 = 11, 23 or 25 are typical initial test values.

Deceleration time (momentum) can be stretched in the

lower speed range:

Tens digit: Percentage of speed range to be

included (0 to 90%).

Loading...

Loading...