15/ 63

4. The engine is started electrically, and the crankshaft rotates without cylinder pressure or with very little

cylinder pressure

·The valve spring is broken.

·The valve is broken.

·Cylinder head gasket gas blowing.

·The spark plug is loose and leaks air.

· Excessive motorcycle carbon deposits on the valves cause the valves to not close tightly.

4. Cylinder compression test

1. Preheat the engine to the normal operating temperature, stop the engine, pull out the spark plug cap and remove the

spark plug (refer to ZT1P77MP maintenance manual for disassembly - 2. Maintenance - spark plug).

2. Install the cylinder pressure gauge connector into the spark plug hole.

3. Fully open the throttle, press the start switch, and use the starter motor to drive the crankshaft and piston to run until

the cylinder pressure gauge reading stops rising (starter motor running time ≤ 15s).

Engine speed: 480-525r/min

Compression pressure: 750-1050KPa (7.65-10.71 Kgf/cm

2

, 108.8-152.3 psi)

① If the measured cylinder pressure is larger than the normal value, it means that there is motorcycle carbon deposit

on the top of the piston or the wall of the cylinder.

②If the measured cylinder pressure is lower than the normal value , pour a small amount of clean engine oil from the

spark plug, turn the crankshaft a few times, so that the piston ring and cylinder wall are evenly covered with oil film, and

retest the cylinder pressure. If the cylinder pressure measured after pouring oil is greater than the last cylinder pressure

value, please dismantle the machine and check the piston and piston ring.

Failure analysis:

a. Piston ring wear.

b. Cylinder wear.

③If the cylinder pressure measured by pouring in the engine oil is the same as the last time (the cylinder pressure is

too small), first measure whether there is any abnormality in the valve clearance of the intake and exhaust valves, and

then disassemble the machine to check whether there is leakage of the intake and exhaust valves, the cylinder block

and cylinder pressure. Check whether the coating of the head gasket is damaged or blown by gas.

5. Cylinder head cover

Cylinder head cover removal

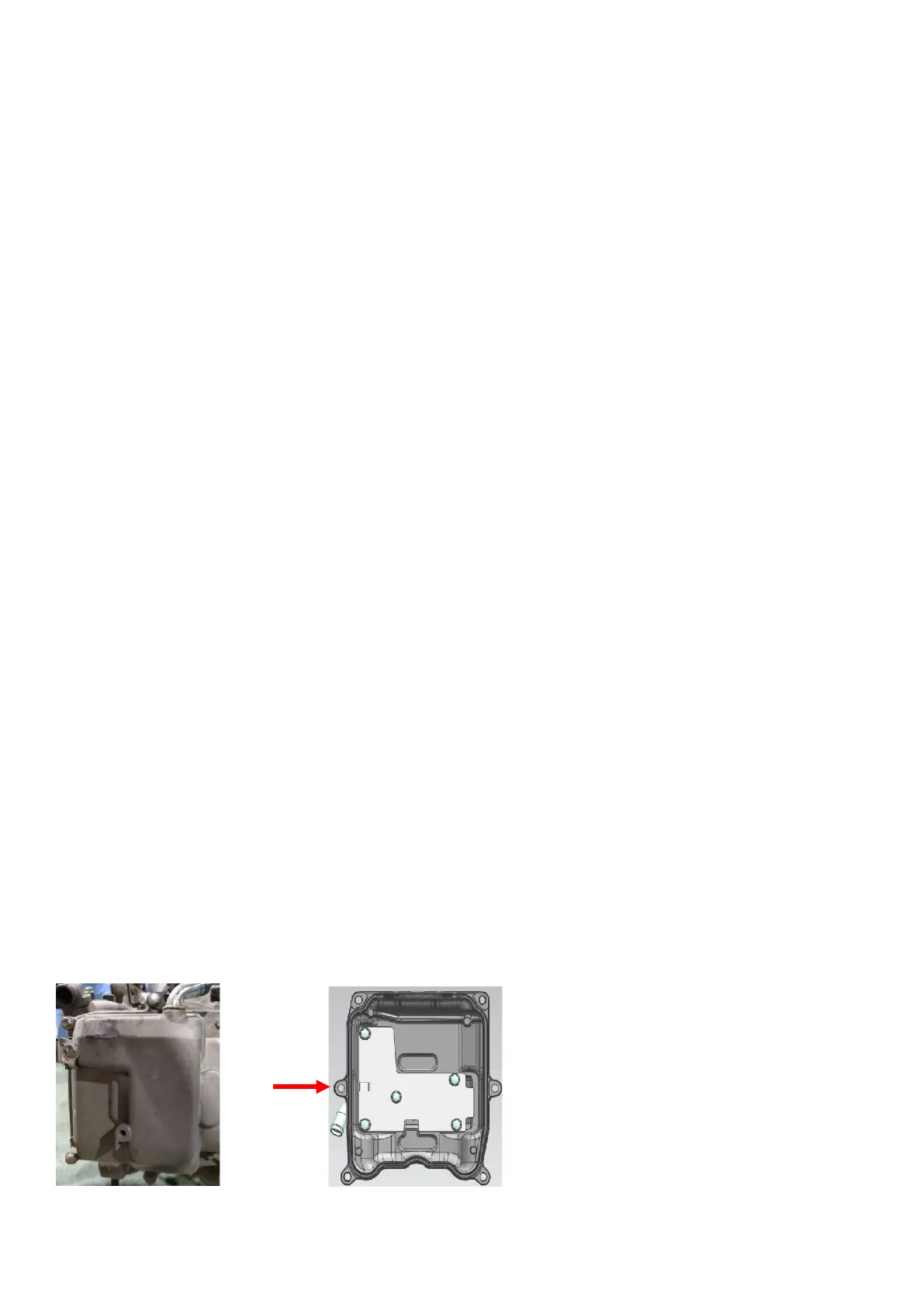

1. As shown in the figure, use the T rod -8# to remove the cylinder head cover locking bolt, and remove the cylinder

head cover wiring harness support, cylinder head cover, and cylinder head cover sealing ring.

Loading...

Loading...