14

3.3 RUNG SUPPORT: Rung supports can be used to reinforce hollow rungs to reduce crushing or collapsing of the rung due

length extending on either side of the Side Rails to install Rung Support fasteners. Install rung support at each LAD-SAF

™

for the system are met.

with the inside dimensions of the rung. See Figure 20 for examples of rung supports.

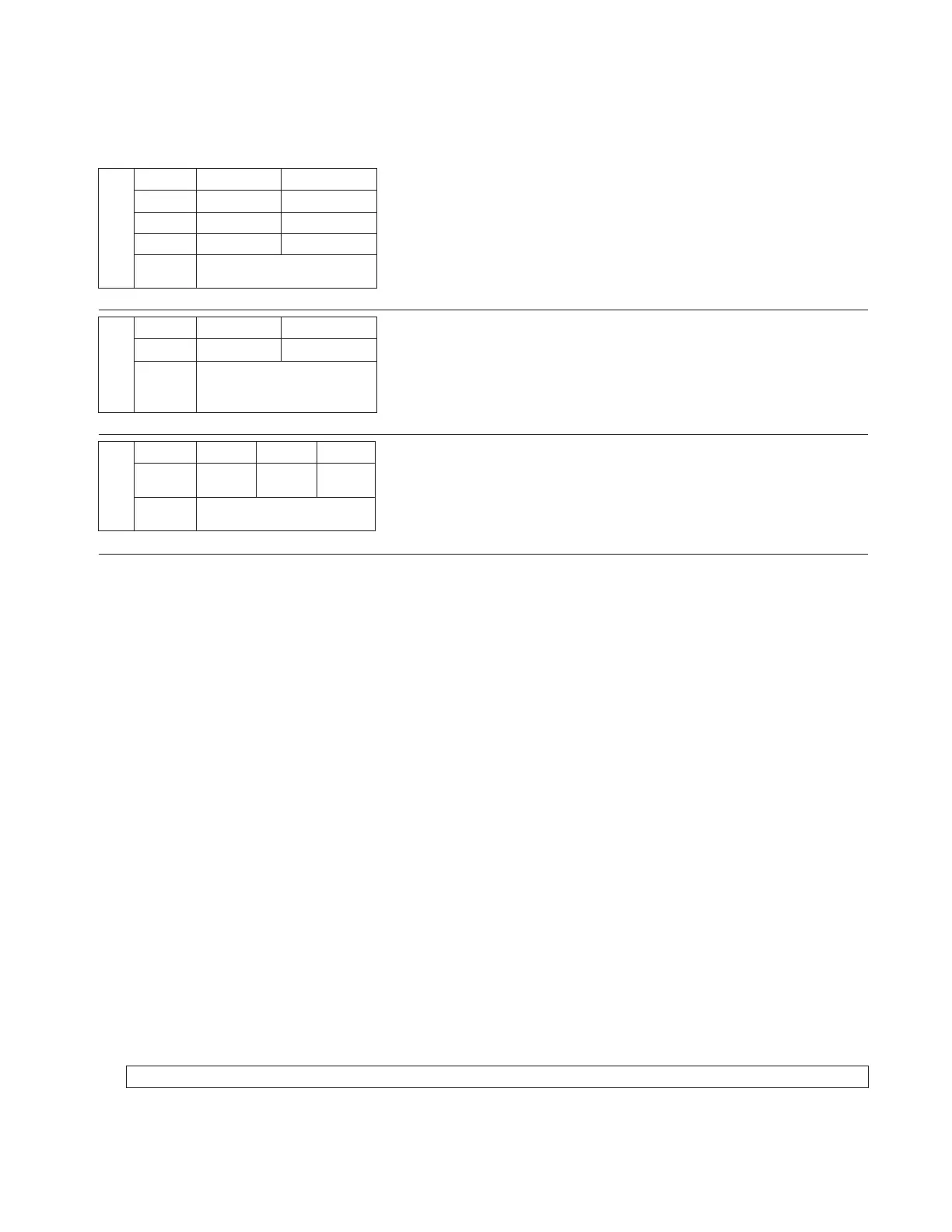

A, Figure 20

Model Ø R

Install at each point indicated below:

6100187 1 in (2.5 cm) 22 in (56 cm)

1. Slide the Rung Support through the open rung.

2. Slide Washers over each end of the Rung Support and secure with Nuts. Tighten

3. Insert Cotter Pins through the holes in each end of the Rung Support. Cotter Pins

should inserted from the top of the Rung Support to prevent them from dropping

out of the holes.

4. Separate and bend the Cotter Pin Legs to ensure Cotter Pins stay in the holes and

the Rung Supports can not slide out of the Rung.

6100188 1 in (2.5 cm) 26 in (66 cm)

6100189 1 in (2.5 cm) 30 in (76 cm)

Materials Aluminum Bar, Stainless Steel

Fasteners

Model Ø R

Install at each point indicated below:

6100151 1 in (2.5 cm) 17 in (43 cm)

1. Slide the Rung Support through the open rung.

2. Insert Cotter Pins through the holes in each end of the Rung Support. Cotter Pins

should inserted from the top of the Rung Support to prevent them from dropping

out of the holes.

3. Separate and bend the Cotter Pin Legs to ensure Cotter Pins stay in the holes and

the Rung Supports can not slide out of the Rung.

Materials Aluminum Bar, Stainless Steel

Fasteners

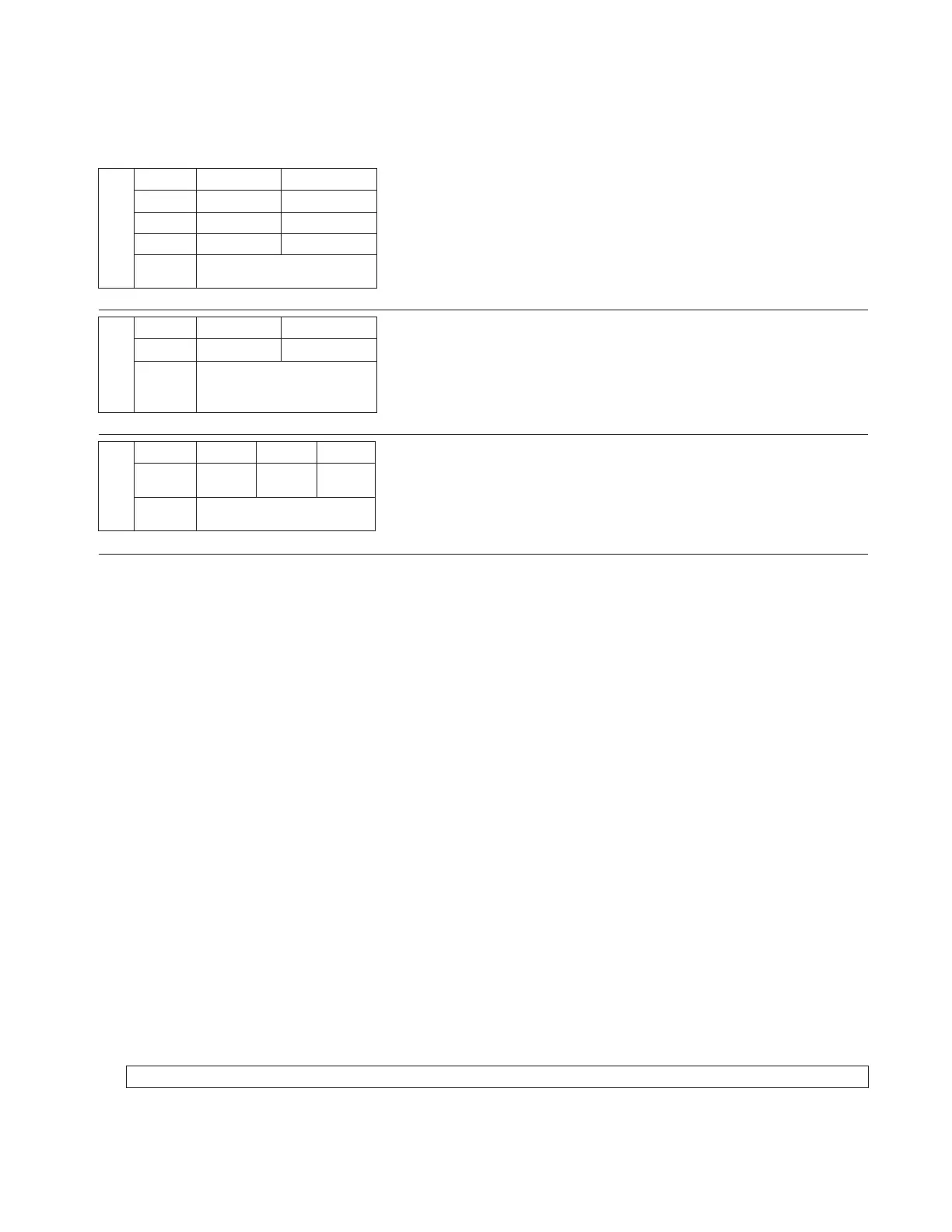

C, Figure 20

Model H W R

Install at each point indicated below:

6100186 .63 in

(1.6 cm)

1 in

(2.5 cm)

19 in

(48 cm)

1. Slide the Rung Support through the open rung.

2. Insert Cotter Pins through the holes in each end of the Rung Support. Cotter Pins

should inserted from the top of the Rung Support to prevent them from dropping

out of the holes.

3. Separate and bend the Cotter Pin Legs to ensure Cotter Pins stay in the holes and

the Rung Supports can not slide out of the Rung.

Materials Aluminum Bar, Stainless Steel

Fasteners

3.4 TOP BRACKET INSTALLATION: Before installing the top bracket it is recommended that the climbing structure be

be positioned to allow users safe access when connecting or disconnecting from the system. The top bracket is typically

mounted in the center of the climbing surface for ease of climbing, but may be located towards the side if required.

A. INSTALLATION OF L1 AND L2 SYSTEMS:

See Figure 2 for a typical installation of the L1 and L2 Systems. The top bracket should be positioned to allow users

safe access when connecting or disconnecting from the system. Do not substitute other fasteners.

Installation procedure:

1. Top Bracket:

2. Bottom Bracket

B. INSTALLATION OF L3 SYSTEM:

See Figure 3 for a typical installation of the L3 System. The top bracket should be positioned to allow users safe

access when connecting or disconnecting from the system. Do not substitute other fasteners.

Installation procedure:

1. Top Bracket:

2. Bottom Bracket

C. INSTALLATION OF M1 AND M2 SYSTEMS:

See Figure 4 for a typical installation of the M1 and M2 System onto a monopole. The top bracket should be

positioned to allow users safe access when connecting or disconnecting from the system. The top brackets are to be

™

system.

Angle Leg and Round Leg Stand-o Installation:

the hardware provided. Do not substitute other fasteners. Torque 3/8-inch fasteners to 20-25 ft-lbs (27-34 N-m).

40-45 ft-lbs (54-61 N-m).

Weld-on Stand-o Installation:

must be perpendicular to the pole surface and in-line with the carrier cable.

; Installations that use the angle leg or round leg stand-o support brackets are limited to one user on the system at a time.

M1 and M2 System Installation:

See Figure 4. Installation procedure:

1. Top Bracket: Install top plate (A), hardware (B) and Single Point Anchor assembly (C) as shown in Figure 4.

2. Bottom Bracket

DISTRIBUTED BY CAI SAFETY SYSTEMS | Phone: (888) 246 6999 | Web: caisafety.com | Email: info@caisafety.com

Loading...

Loading...