SETUP

LEREF "Verzeichnis Ueberschrift" \* MERGEFORMAT Index

Fehler! Verwenden Sie die Registerkarte 'Start', um Verzeichnis Ueberschrift

dem Text zuzuweisen, der hier angezeigt werden soll.Contents

You may need to contact the manufacturer.

The time constant for the winding is the time that would elapse until the hot spot reaches

the steady-state final value divided by five.

Example:

With a time constant of 3000 seconds, it is assumed that after 5 x 3000 s = 15,000 s, mean-

ing about 4 hours, the steady-state final value of the hot-spot temperature will be reached.

The number of submenus is determined in proportion to the number of predefined cooling

stages. 'Cooling stage 0' means that there is no cooling at all. 'Cooling stage 0 (oil pump)'

only appears when one of the two cooling types is configured ON/OF or ON/OD. The pa-

rameters for each of the cooling stages (fan group) are set for the transformer in the

'Cooling stage 1,2,...' menus.

5.1.1.3 Hot-spot temperature increase Hg

r

The hot-spot temperature increase (Hot-Spot Incr.) is a transformer-specific parameter and

can generally be taken from the transformer's data sheet.

You may need to contact the manufacturer.

If manufacturer data is not available for 'Hg

r

', use the values specified in the IEC standard.

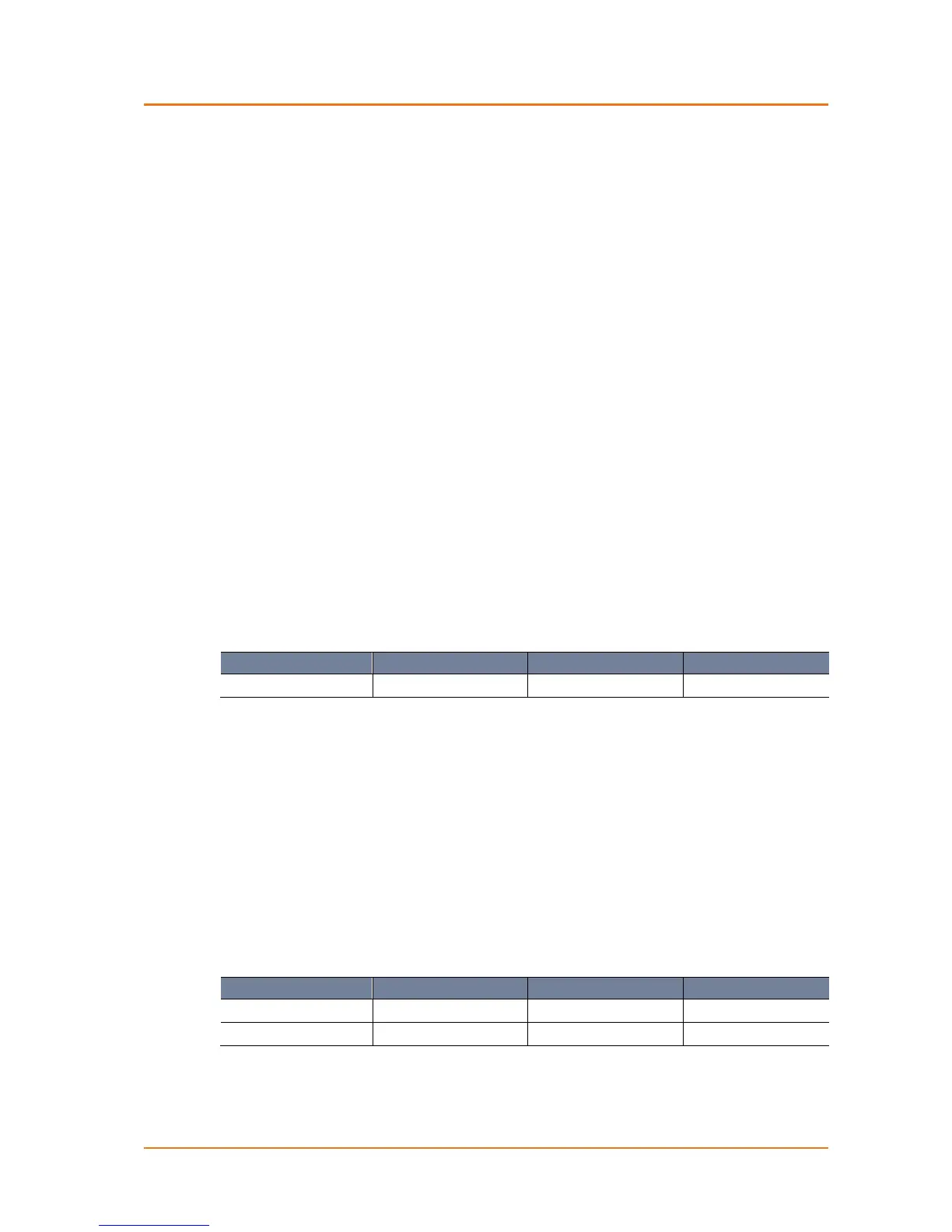

The standard indicates that different values should be used for the hot-spot temperature

'Hg

r

' based on the type of cooling used for medium and large power transformers.

A value of 23 K is suggested for distribution transformers with cooling type ONAN.

5.1.1.4 Winding exponent y

Winding exponent 'y' is a transformer-specific parameter and can generally be taken from

the transformer's data sheet.

You may need to contact the manufacturer.

If no manufacturer data is available for 'y', it is recommended to use the values specified in

the IEC standard.

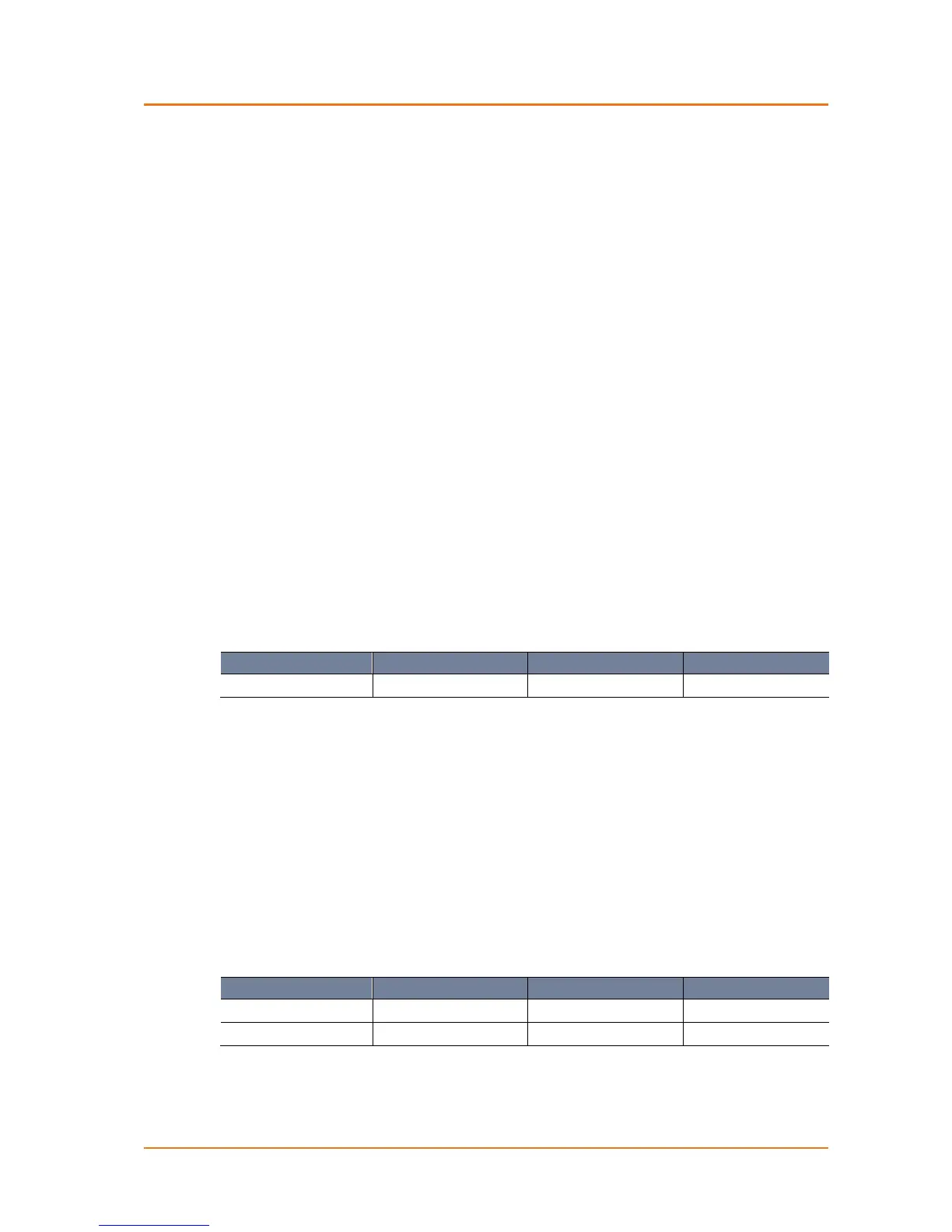

The standard indicates that different values should be used for winding exponent 'y' based

on the type of cooling used for medium and large power transformers.

Loading...

Loading...