28

TEMPERATURE & PRESSURE RELIEF VALVE

At least once a year, the temperature and pressure relief valve,

Figure 1, must be checked to ensure that it is in operating condi-

tion. Lift the lever at the top of the valve several times until the

valve seats properly and operates freely.

If water does not fl ow, remove the valve and inspect for obstruc-

tions or corrosion. Have a qualifi ed service agent replace with

a new valve of the recommended size as necessary. Do not

attempt to repair the valve, as this could result in improper opera-

tion and a tank explosion. In areas with poor water conditions, it

may be necessary to inspect the T&P valve more frequently.

THE WATER PASSING OUT OF THE VALVE DURING THIS

CHECKING OPERATION MAY BE EXTREMELY HOT. AVOID

CONTACT AND DISCHARGE SAFELY TO PREVENT WATER

DAMAGE.

DRAINING

It is recommended that the tank be drained and fl ushed every

6 months to remove sediment which may build up during op-

eration. The water heater should be drained if being shut down

during freezing temperatures. To drain the tank, perform the

following steps:

Turn off the gas to the water heater at the manual gas shut-

off valve.

Open a nearby hot water faucet until the water is no longer

hot.

Close the cold water inlet valve.

Connect a hose to the drain valve and terminate it to an ad-

equate drain or external to the building.

Open the water heater drain valve and allow all of the water

to drain from the tank. Flush the tank with water as needed

to remove sediment.

Close the drain valve, refi ll the tank, and restart the heater as

directed in this manual.

If the water heater is going to be shut down for an extended

period, the drain valve should be left open.

IMPORTANT: Condensation may occur when refi lling the tank

and should not be confused with a tank leak.

I

1.

2.

3.

4.

5.

6.

CATHODIC PROTECTION - ANODE

The anode rod within the tank is designed to be slowly consumed

cathodically, minimizing corrosion in the glass-lined tank. A hy-

drogen sulfi de (rotten egg) odor may result if water contains high

sulfate and/or minerals. Chlorinating the water supply should

minimize the problem. (See EXTENDED NON-USE PERIODS).

NOTE: Anode must remain installed (except for inspection) to

avoid shortening tank life. See LIMITED WARRANTY. Replace

as necessary.

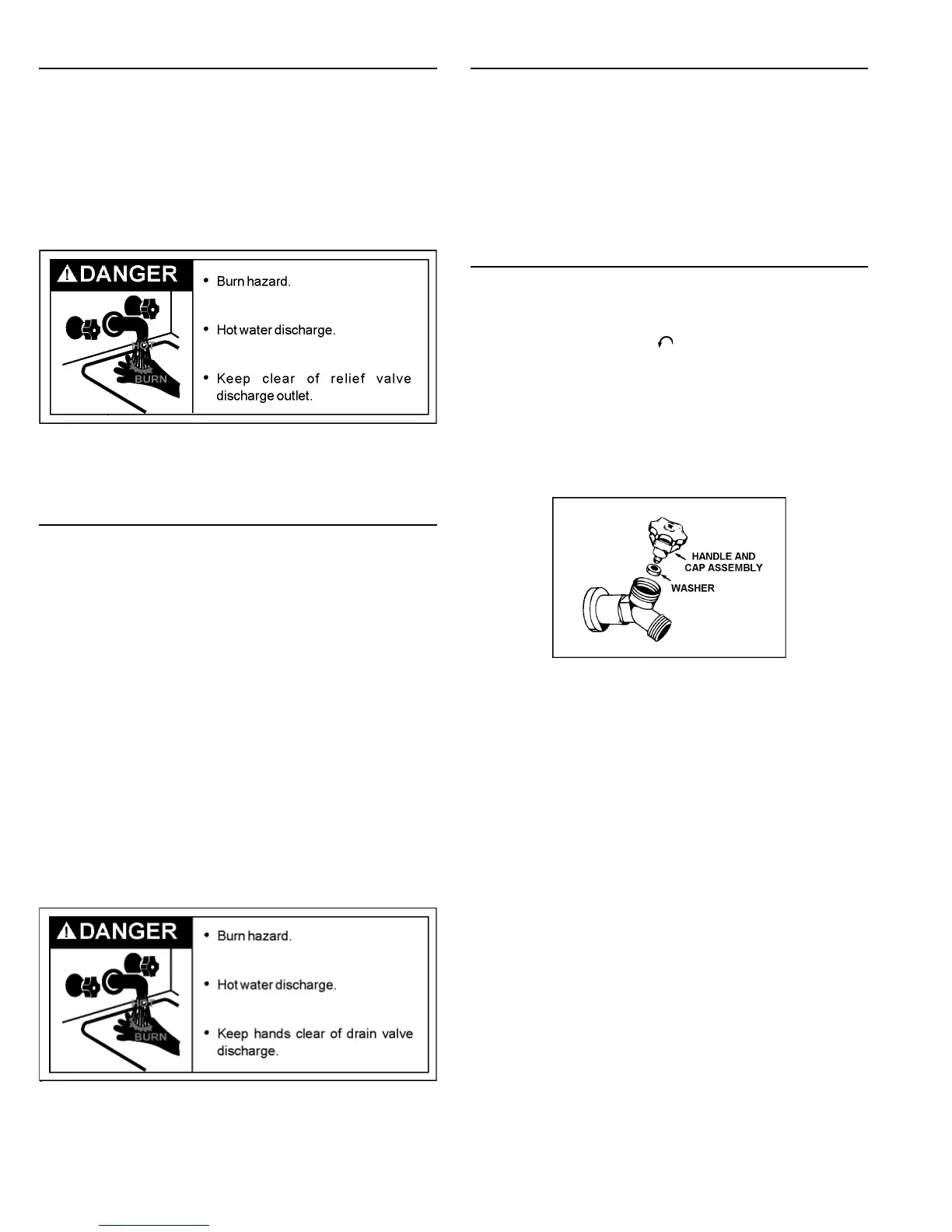

DRAIN VALVE WASHER REPLACEMENT

(See Figure 28)

1. Turn “OFF” gas supply to water heater.

2. Follow “Draining” instructions.

3. Turning counterclockwise (

), remove the hex cap below

the screw handle.

4. Remove the washer and put the new one in place.

5. Screw the handle and cap assembly back into the drain

valve and retighten using a wrench. DO NOT OVER TIGHT-

EN.

6. Follow instructions in the “Filling The Water Heater” section.

7. Check for leaks.

8. Follow the lighting instructions in the “Lighting” section to

restart the water heater.

FIGURE 28

Loading...

Loading...