How to fix weighing pan error on A&D Scales?

- MMr. Justin RaySep 10, 2025

If the A&D Scales show a weighing pan error because the weight value is too light, confirm that the weighing pan is properly installed and calibrate the balance.

How to fix weighing pan error on A&D Scales?

If the A&D Scales show a weighing pan error because the weight value is too light, confirm that the weighing pan is properly installed and calibrate the balance.

What does sample mass error mean on A&D Scales?

If the A&D Scales display a sample mass error, it means the balance can't store the sample for counting or percent mode because it's too light. Use a heavier sample.

How to resolve unit mass error on A&D Scales?

If the A&D Scales display a unit mass error, it means the sample unit mass for the counting mode is too light. Add samples to reach the specified number and then press the PRINT key.

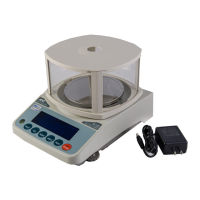

| Capacity | 200 g |

|---|---|

| Readability | 0.001 g |

| Repeatability (σ) | 0.001 g |

| Linearity | ±0.002 g |

| Stabilization Time | 2 seconds |

| Display | LCD |

| Interface | RS-232C |

| Calibration | Internal |

| Power Supply | AC adapter |

| Operating Temperature | 5°C to 40°C |

| Power Source | AC adapter |

| Units of Measure | g, oz, lb, ozt, ct, mom, dwt, GN |

Provides an overview of the manual's structure and purpose.

Highlights the key capabilities and design aspects of the FZ-i/FX-i series balance.

Instructions for safely removing the balance and its components from the packaging.

Essential guidelines for proper installation and initial setup to ensure accurate weighing.

Safety and operational advice for using the balance during and after measurements.

Explanation of balance indicators, symbols, and the function of each key.

Description of available units of weight and different weighing modes.

Step-by-step guide for standard weighing in gram mode.

Instructions for using the counting (PCS) and percent (%) weighing modes.

How to perform statistical analysis on weight data.

Adjusts the balance sensitivity to environmental conditions for stable readings.

Overview of available calibration procedures: internal and external weights.

Procedure for calibrating the balance using its built-in mass.

Procedure to correct internal mass using an external weight and calculation.

Alternative method to correct internal mass using external weight calibration.

Step-by-step guide for calibrating the balance with an external weight.

Configuration of switches to protect parameters from unintentional changes.

Restores balance parameters to factory default settings.

Introduction to the structure and navigation of the balance's function table.

Configuration of environmental parameters and display behavior.

Settings for controlling data transmission via RS-232C interface.

Explanation of different data output formats (A&D, DP, KF, MT, NU, CSV).

Illustrations of data output for various formats and conditions.

Description of capacity indicator and statistical calculation modes.

Setting and using the built-in clock and calendar.

Configuration and use of the comparator for limit checking.

Setting the balance ID and understanding GLP report output.

Formats and examples of GLP reports for calibration and weight data.

Using the balance's underhook for specific measurements like density.

Converting weight data using a programmable coefficient.

Technical details and pin assignments for serial communication.

Instructions for connecting printers and computers.

Connecting to PCs and using Windows Communication Tools.

List of commands for controlling the balance via RS-232C.

Procedures for cleaning, care, and verifying balance performance.

List of error displays and their descriptions and solutions.

Guidance on when and how to contact a dealer for service.

USB connectivity for data transfer to PC.

LAN connectivity for networking the balance.

Battery option for portable use.

Detailed technical data including weighing capacity, display, and environmental specs.

Physical dimensions of the balance models.

Glossary of terms and an index for quick reference.