48 Guidelines for planning the cabinet installation

Note 1: The power cable shields can also be grounded to the drive module grounding

terminals.

Note 2: See also section Required free space, page 55.

Arranging the grounding inside the cabinet

Arrange the grounding of the drive module by leaving the contact surfaces of the fastening

points unpainted (bare metal-to-metal contact). The module frame will be grounded to the

PE busbar of the cabinet via the fastening surfaces, screws and the cabinet frame.

Alternatively, use a separate grounding conductor between the PE terminal of the drive

module and the PE busbar of the cabinet.

Ground also the other components in the cabinet according to the principle above.

Selecting the busbar material and preparation of the

joints

Note the following when you use busbars:

• Tin-plated copper is recommended but aluminum can also be used.

• The oxide layer from aluminum busbar joints must be removed and suitable anti-

oxidant joint compound applied.

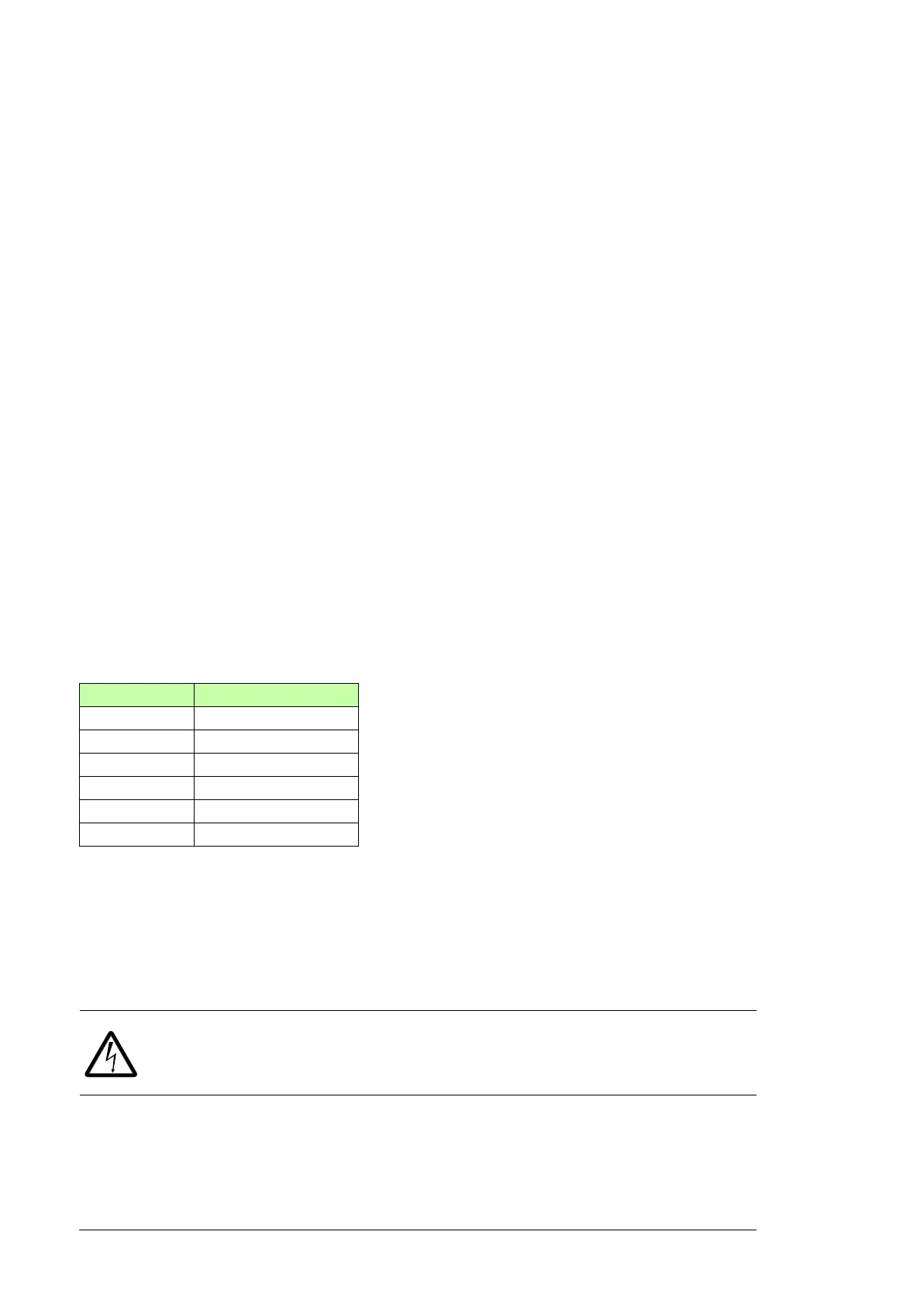

Tightening torques

Apply the following torques to grade 8.8 screws (with or without joint compound) that

tighten electric contacts.

Planning the fastening of the cabinet

Note the following when you plan the fastening of the cabinet:

• Fasten the cabinet to the floor from the front and to the floor or wall from the back.

• Always fasten the drive module from its fastening points to the cabinet. For details,

see the module installation instructions.

WARNING! Do not fasten the cabinet by electric welding. ABB does not assume

any liability for damages caused by electric welding as the welding circuit can

damage electronic circuits in the cabinet.

Screw size Torque

M5 3.5 N·m (2.6 lbf·ft)

M6 9 N·m (6.6 lbf·ft)

M8 20 N·m (14.8 lbf·ft)

M10 40 N·m (29.5 lbf·ft)

M12 70 N·m (52 lbf·ft)

M16 180 N·m (133 lbf·ft)

Loading...

Loading...