2-8MN1240

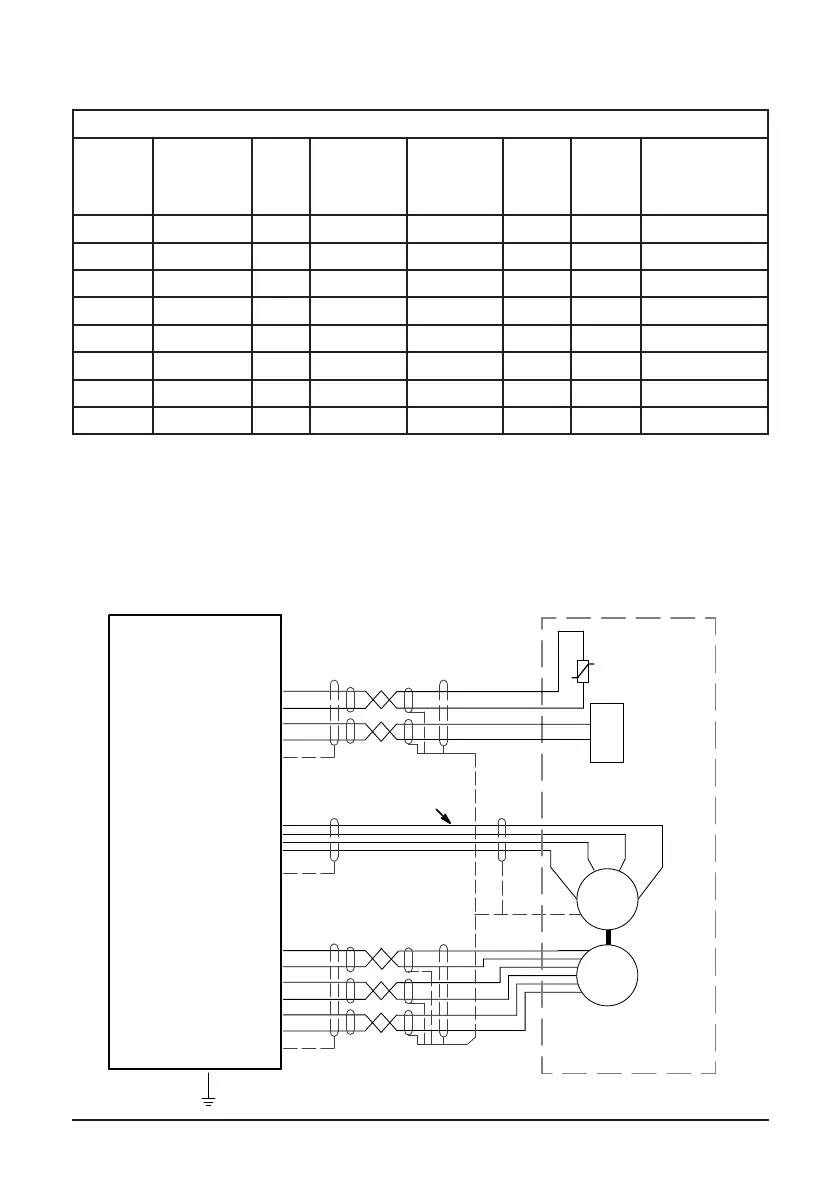

Table 2-1 Brake Specifications

Brake data for BSM and SSBSM

Motor

Code

Brake

Holding

Torque Nm

(lb-in)

Watts Brake

voltage

(Vdc)

Brake

current

(amps)

Set

Time

(ms)

Release

Time

(ms)

Brake inertia

Kg-cm²

(lb-in-s²)

BSM50N 1.1 (10) 12.4 24 0.52 3 20 0.019 (0.000017)

BSM63N 2 (18) 17 24 0.71 16 43 0.018 (0.000016)

BSM80 4.5 (40) 17 24 0.71 9 48 0.125 (0.000111)

BSM90 15.8 (140) 22 24 0.92 14 110 0.181 (0.00016)

BSM100 39.5 (350) 19 24 0.79 22 195 0.723 (0.00064)

BSM25C 1.7 (15) 9.6 24 0.4 16 27 0.034 (0.00003)

BSM33C 15.8 (140) 21.6 24 0.9 14 110 0.181 (0.00016)

BSM132C 101.7 (900) 76 24 3.17 129 163 17.277 (0.01529)

Note: All standard brakes used on BSM motors are 24 Vdc. The application needs to provide this voltage to release

the brake. The brake is a safety brake only and not intended to be used to decelerate loads. Contact ABB for details.

Detailed engineering drawings are available upon request.

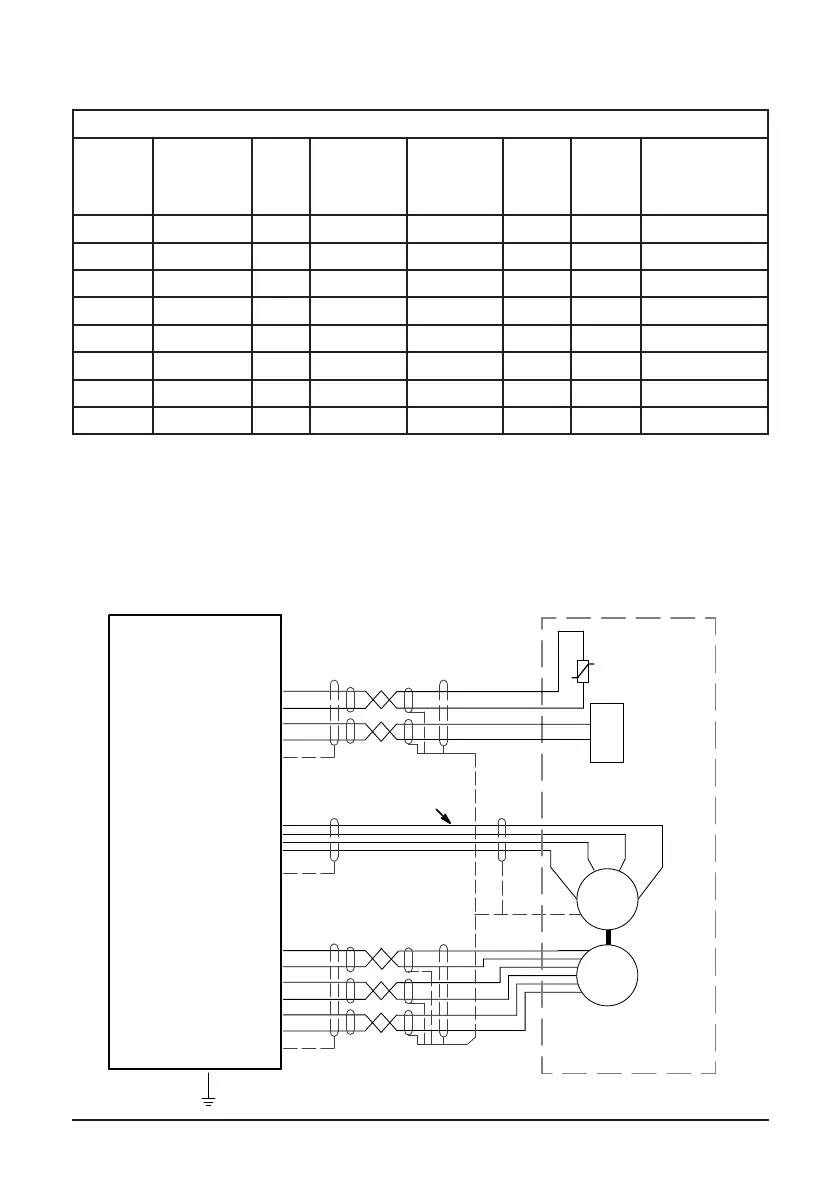

Electrical Connections

Overview Figure 2-7 shows typical connections to a control. Note all wiring should be

600volts.

Figure 2-7 Typical Connections to Motor Control

AC MotorU

V W

G

Control

Feedback

Motor

Holding

Brake

Motor

Temperature

Switch

Shielded

Twisted Pair Wire

Shielded

Twisted Pair Wire

Feedback

Connector

Motor

Connector

Motor Ground Wire

Motor Temperature Input

Holding Brake Connector

Single Point Ground

Shielded Motor Cable

All wiring should have 600V rated insulation.

Loading...

Loading...