22

1ZSE 5492-128 en, Rev. 4

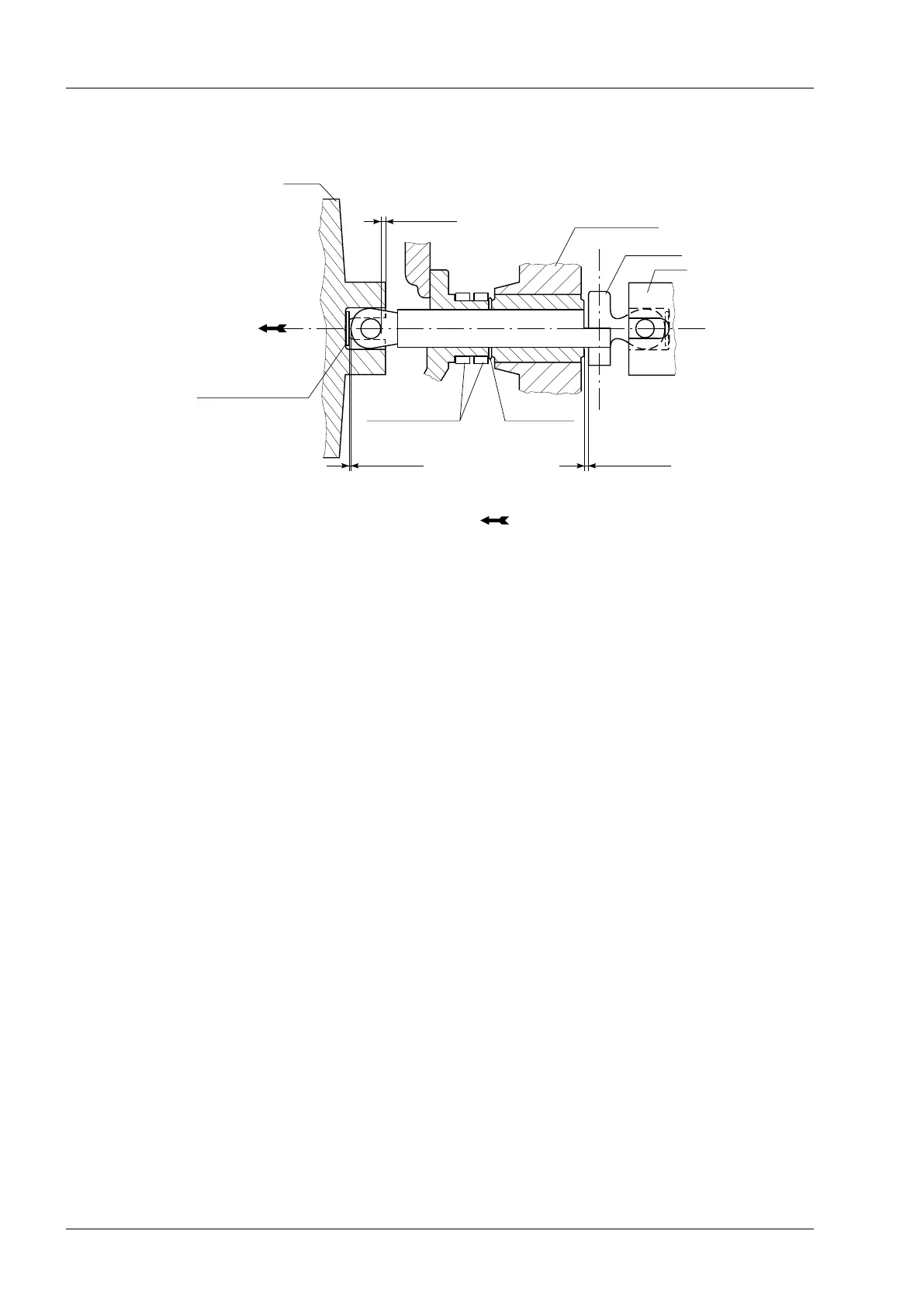

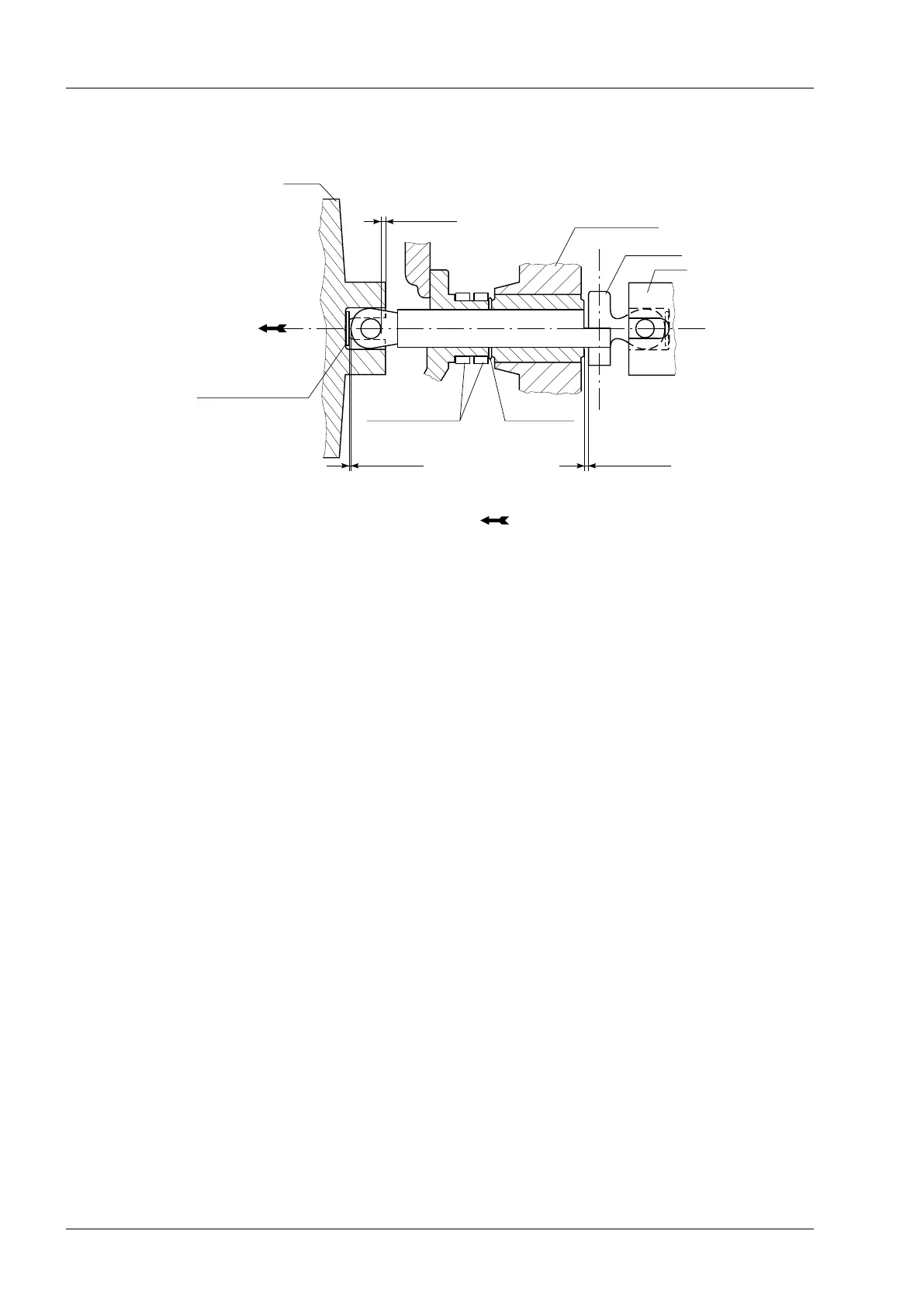

1) The shaft must be pushed as much as possible

in the direction shown by the arrow

Shaft

1)

Min. 0 mm

Min. 2 mm Min. 0,1 mm

Epoxy moulding

Current collector

Shaft

Presspahn washer for

axial play adjustment

Washer/shim

Coupling

fm_00103

3 Repairs and adjustments

18. Close the front cover and tighten the domed nuts with a torque of 42 Nm.

19. Reconnect the conductors inside the transformer, loosened in step 7.

20. Rell the transformer with oil. For information about oil lling, refer to the documentation

for the transformer.

21. Fill the on-load tap-changer with oil. For information about oil lling, see the Mainte-

nance Guide.

3.2

Replacement of gaskets between barrier board of steel and selector switch unit

3.2.1 General

Follow section 3.1 where applicable and with following exceptions:

- Distance pieces of wood or pressboard thickness approximately 13 mm.

- Polyvinylacetate adhesive is not needed.

- Instead of section 13 e:

The studs are lubricated with grease for ball bearings. Tighten the M8 nuts with dyna-

mometric wrench 13 Nm, the rst time in sequence according to Fig. 6 and the second

time without special sequence. Re-tightening of the nuts shall be done earliest 5 hours

after the previous tightening with 13 Nm without special sequence.

3.3 Replacement of front cover and top cover gaskets

3.3.1 General

This instruction guides you on how to attend to an oil leakage.

3.3.2 Tools required

■ Box wrench (19 mm)

■ Pump with connection tting the oil valve

Fig. 7. Play check/adjustment.

Loading...

Loading...