L6555

Emax

22/74

Doc. no.

Model

Apparatus

Scale

Page No

1SDH000460R0002

8.3.6. Electrical and mechanical accessories

- Check that the accessories are fi xed to the switch

- Check that the electrical accessories are connected to the switch

- Reduction gear: after 10000 operations check brushes for wear and replace the reduction gear if necessary.

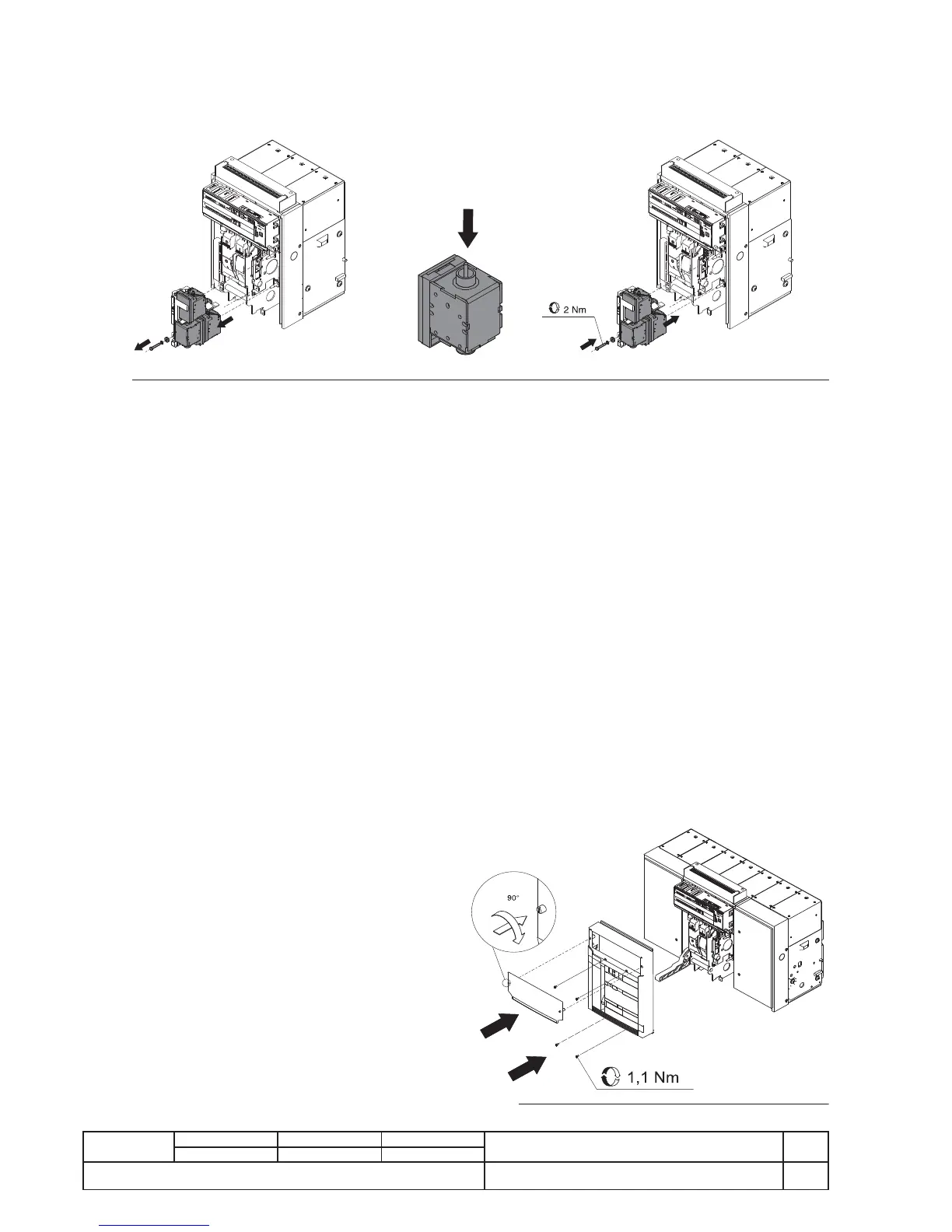

- Check that the releases (SOR-UVR-SRC) are in good condition (no excessive wear, overheating, breakages) Fig. 36.

- Check that the mechanical operation counter is operating correctly (if applicable) by running an operation on the switch.

Fig. 36

8.3.7. Protection releases

- Supply the protection release from a PR030/B battery unit.

- Check that the protection release is working correctly: run “Trip Test” (PR121, PR122, PR123) and “Autotest” (PR122, PR123)

for release.

- Use release PR122 or PR123 to check that there are no alarms on the display and via front LEDs.

- Use release PR121 to check that there are no alarms via front LEDs.

- Check that the cables are correctly connected to the release modules and to the release (if applicable).

- On PR122 and PR123 check the wear percentage to the switch contacts.

- At the end, remove the battery unit PR030/B from the relay.

Consult this manual for details about release PR121.

Consult manual 1SDH000460R0102 for details about releases PR122-PR123.

8.3.8. Test with SD Testbus2 (optional)

- Connect unit BT030 or BT030-USB to the relay to be tested.

- Run the programme SD.TestBus2 on a PC with a Bluetooth or USB connection, depending on the version of BT030 used.

- Once the connection between the relay and PC has been installed, check that there are no alarm signals from the relay; other-

wise, consult the paragraphs ‘Error Messages’ and/or ‘Troubleshooting’ in this manual.

- In normal operating conditions the trip test and the autotest can be run (depending on the type of relay); for future checks, we

advise inserting the current date in the User Data and/or Tag Name area. These data will be stored inside the relay.

- Remove the BT030 or BT030-USB from the relay.

Consult this manual for details about release PR121.

Consult manual 1SDH000460R0102 for details about releases PR122-PR123.

8.3.9. Maintenance operations; fi nal checks

- Refi t all parts and if necessary reconnect the auxiliary supply.

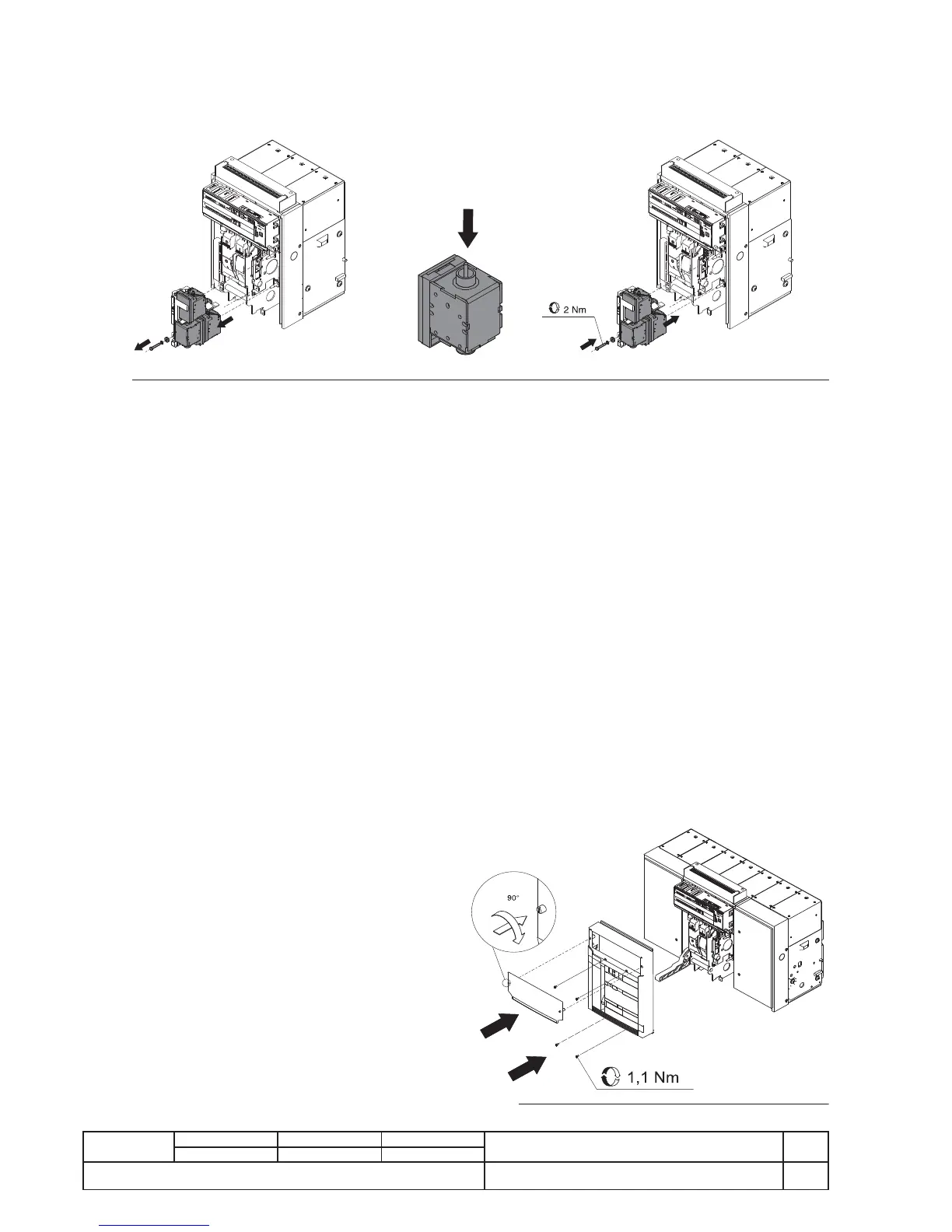

- Refi t the cap as indicated in fi gure 37.

- Return the movable part to the TEST-ISOLATED position.

- Use the different auxiliaries in turn to run the following 10

operations:

- Opening (both local and remote as applicable)

- Closing (both local and remote as applicable)

- Release by trip test from the relay

- Check the operations according to this sequence:

- Open - Springs unloaded

- Open - Springs loaded

- Closed - Springs unloaded

- Closed - Springs loaded

- Check operation of the accessories, if present

- Check operation of reduction gear (if present)

- Check operation of minimum voltage release (if present)

- Check operation of opening release (if present)

- Check operation of closing release (if present)

- Check operation of auxiliary contacts of switch (if present)

- Check operation of lock of switch in open position

(with key or padlocks) (if present)

Fi

Loading...

Loading...