-- 1 2 --

ba39d1ea

8 FAULT--TRACING

Try these recommended checks and inspections before sending for an authorised

service technician.

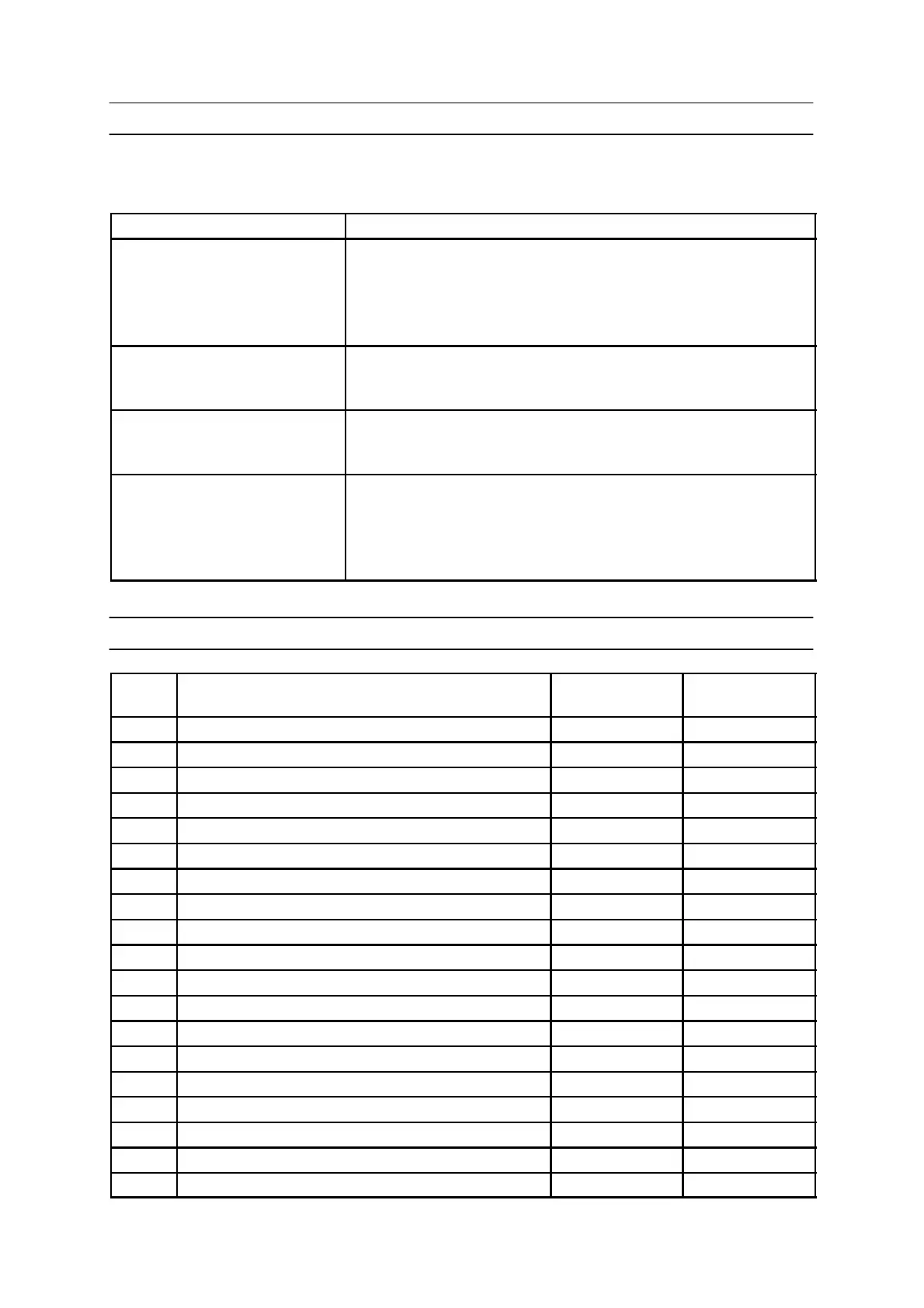

Type of fault Action

No arc. S Check that the mains power supply switch is turned on.

S Check that the welding current supply and return cables are

correctly connected.

S Check that the correct current value is set.

S Check that the fuse is intact.

The welding current is interrup-

ted during welding.

S Check whether the thermal cut--outs have tripped (indicated

by the orange lamp on the front panel).

S Check the mains power supply fuses.

The thermal cut--out trips fre-

quently.

S Check to see whether the dust filter is clogged.

S Make sure that you are not exceeding the rated data for the

power source (i.e. that the unit is not being overloaded).

Poor welding performance. S Check that the welding current supply and return cables are

correctly connected.

S Check that the correct current value is set.

S Check that the correct wire is being used.

S Check the mains power supply fuses.

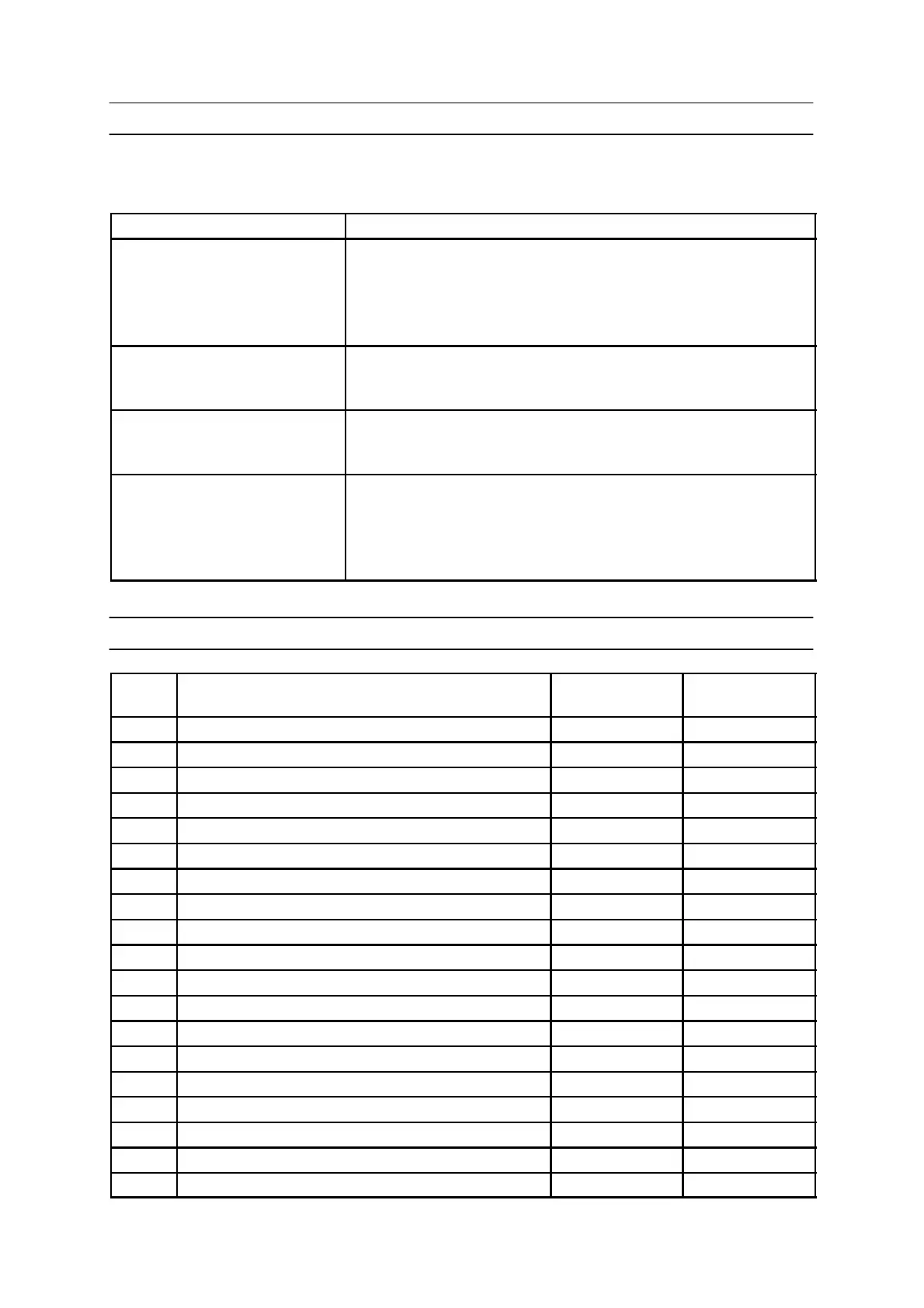

9 LISTOFFAULTCODES

Fault

code

Description Welding data

unit

Power unit

1 EPROM memory error x x

2 RAM memory error x x

3 External Read/Write RAM memory error x

4 5 V power supply x x

5 High DC intermediate voltage x

6 High temperature x

7 High primary current x

8 Mains power supply 1* x x

9 Mains power supply 2* x

10 Mains power supply 3* x

12 Communication error (warning) x x

14 Communication error (bus off) x

15 Messages lost x x

18 Lost contact with the power unit x

19 Incorrect set values in external RAM x

20 Unacceptable settings stored in RAM x

21 Incompatible settings stored in RAM x

22 T ransmitter buffer overflow x

23 Receiver buffer overflow x

Loading...

Loading...