-- 8 --

ba39d1ea

5.3 Mains power supply

Check that the welding power source is connected to the

correct mains power supply voltage, and that it is protected by

the correct fuse size. A protective earth connection must be

made in accordance with regulations.

Rating plate with supply connection data

Recommended fuse sizes and minimum cable area

MigRob 500 400 V 3μ 50 Hz

Mains voltage 400 V

Mains cable area mm

2

4G6

Phase current, IRMS 31 A

Fuse

Anti--surge

Type C MCB

35 A

40 A

Note! The mains cable areas and fuse sizes as shown above are in accordance with Swedish

regulations. Use the welding power source in accordance with the relevant national regulations.

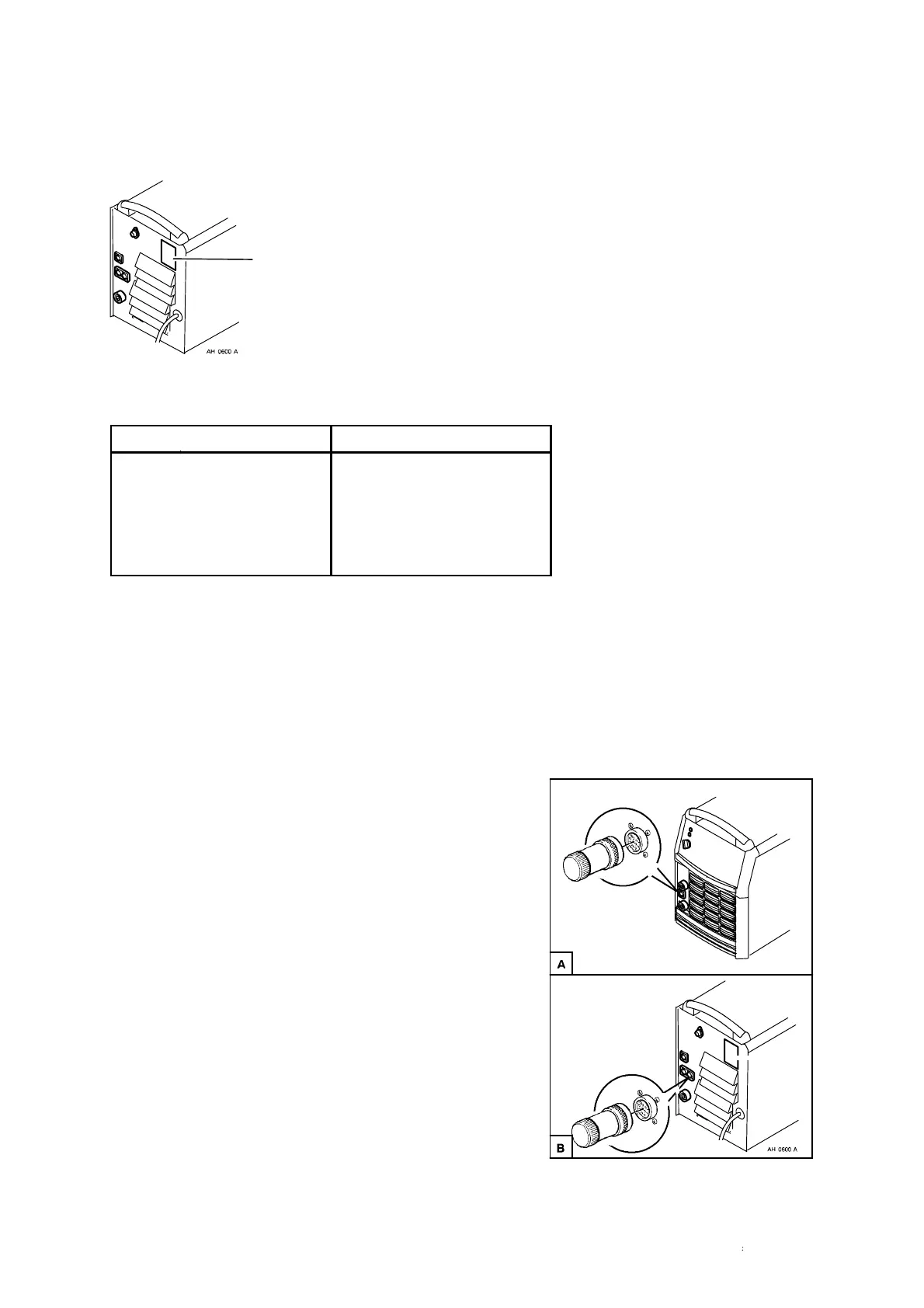

5.4 Terminating resistors

The ends of the CAN bus must be fitted with terminating resistors to avoid

communication interference.

Inte rn al CAN--bus

One end of the CAN--bus is at the welding data unit,

which has an integral resistor. The other end is at the

power source and must be fitted with the terminating

resistor, as shown in figure A.

External CAN--bus

The power source has two connections for the

external CAN--bus, ”EXT CAN IN” and

”EXT CAN OUT”.

The cable from the robot system is connected to the

connector m arked ”EXT CAN IN”. If the power

source is located at the end of the CAN--bus, the

terminating resistor must be located in ”EXT CAN

OUT” in accordance with figure B. If the power

source is not the final unit on the CAN--bus, ”EXT

CAN OUT” is u sed to connect the bus on to

additional CAN units (in such cases the terminating

resistor is placed in the final unit on the bus.)

Loading...

Loading...