-- 6 --

ba39d1ea

3 INTRODUCTION

MigRob 500 is a welding power source intended for MIG/MAG welding.

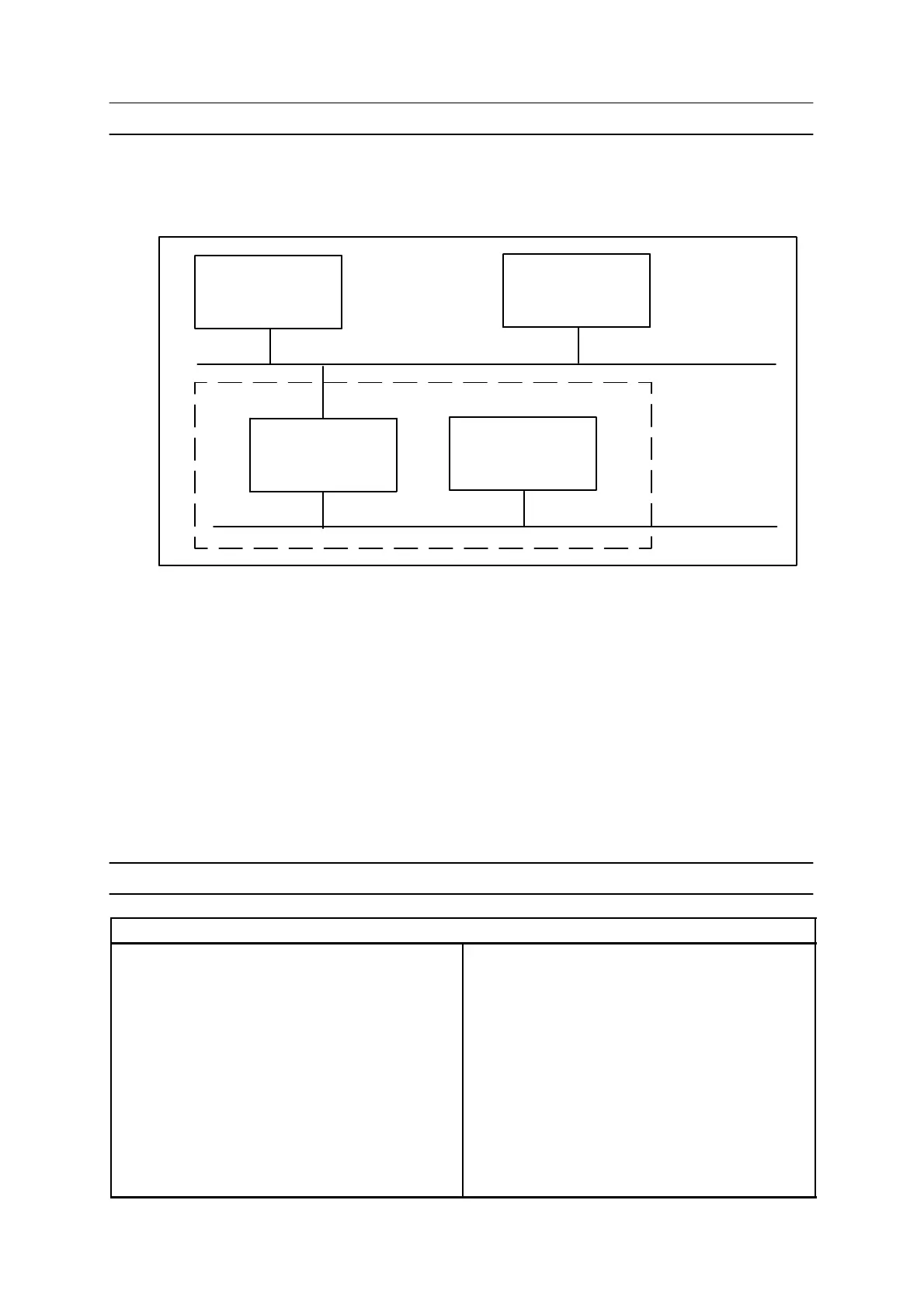

The welding power source comprises a control unit and a welding data unit.

All m an-- machine communication is performed from the robot’s control panel.

Control unit

Wire feed unit

Robot

External CAN--bus

Welding power source

Welding data unit Control unit

Internal CAN--bus

3.1 Communication

All exchange of information between the welding equipment and the robot system

takes place via a CAN--bus. The welding data unit in the welding power source

handles this communication.

3.2 Equipment

The MigRob 500 power source is supplied with 2 terminating resistors, a 5 m return

cable and an instruction manual.

Note! One terminating resistor for the internal bus and one for the external bus.

4 TECHNICAL DATA

MigRob 500

Mains voltage 400 V, ±10%, 3∼ 50/60 Hz

Primary current I

max

39 A

No--load power demand when in the energy--sa-

ving mode, 6.5 min. after welding

50 W

Setting range 8--60 V / 16--500 A

Maximum permissible load at

60% duty cycle

100% duty cycle

500 A / 39 V

400 A / 34 V

Power factor at maximum current 0.85

Efficiency at maximum current 86%

Open --circuit voltage 72 -- 88 V

Loading...

Loading...