19

INSTALLATION, OPERATIONS AND MAINTENANCE MANUAL

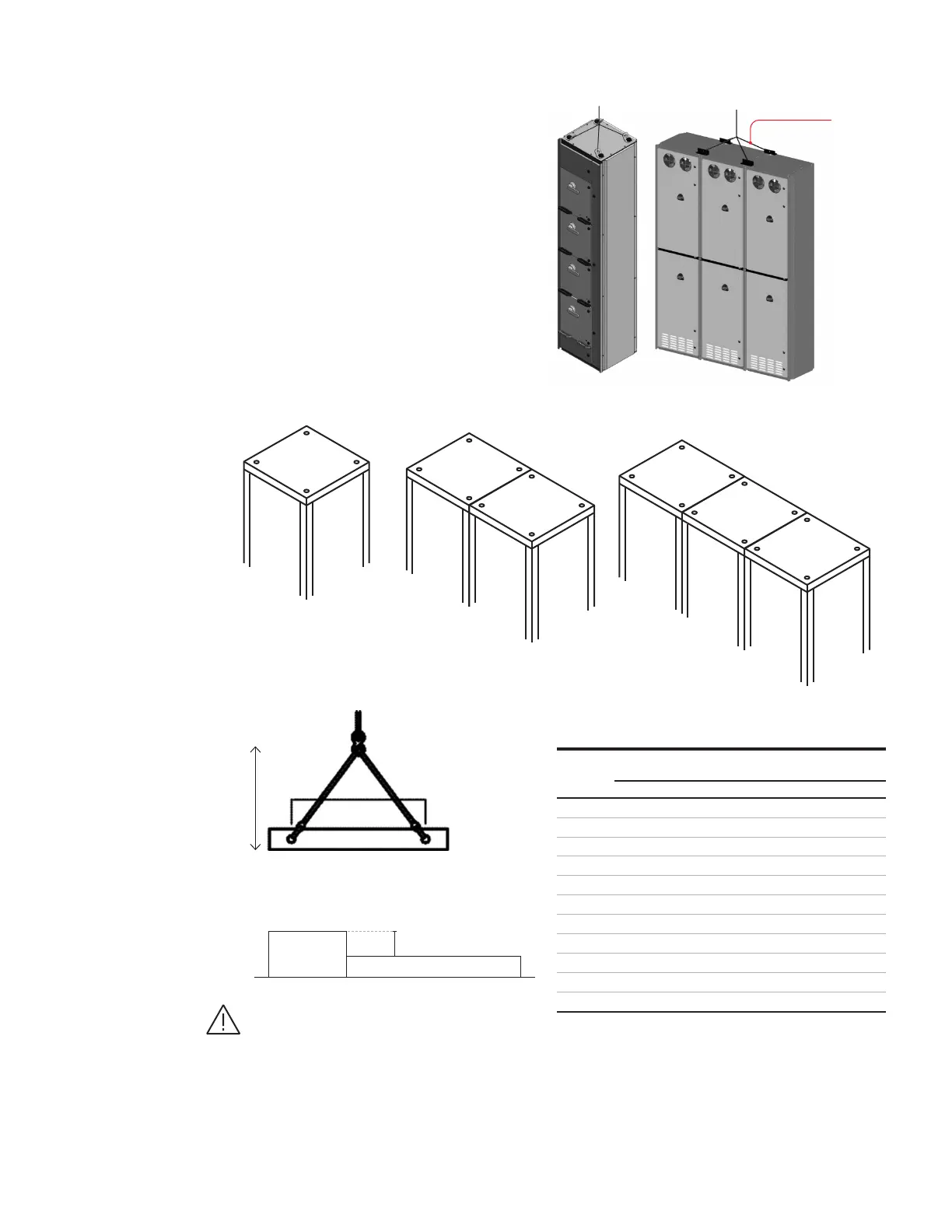

Crane handling

MCC sections are equipped with lifting angles to

enable unloading and positioning using a crane.

Do not fasten any lifting device directly to the

vertical sections. Lift only using the lifting angles.

You can remove the lifting angles after the section

is in position. If removed, replace the bolts.

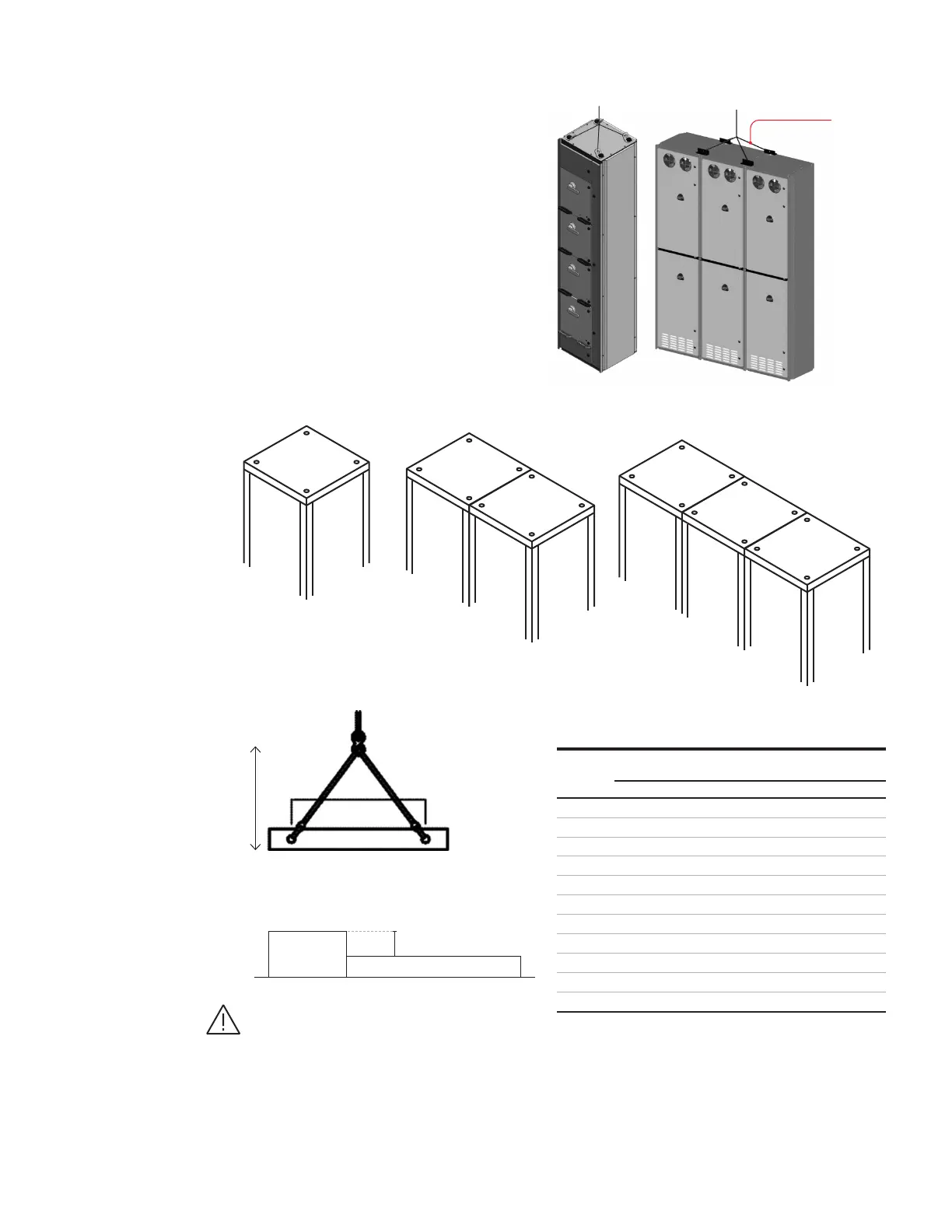

The optimal lifting rope angle at the crane hook

is 45°. The maximum rope loading is reduced for

larger rope angles, as shown in Fig. 19.

Use only slings and rigging hardware that comply

with the applicable sections of ASME B30.20,

ASME B30.26 and ASME B30.9.

—

20

—

19 Crane transport

—

20 Arrangement of

lifting angles

—

21 Transport with

pallet jack warning

—

19

Rope

angle

120°

*As per the following standards: DIN 83325 for Hamp,

DIN 83330 for Perlon, DIN 15060 for Steel

—

Table 3. Guide values for permissible rope

Rope

Diameter

Permissible load of a four rope arrangement @

120º lifting angle

Hemp rope Perlon ropes Steel ropes

mm Kg lbs Kg lbs Kg lbs

- - - -

- -

- -

- -

- -

- - - -

- - - -

Lifting eyes for 1 section Lifting eyes for 2 sections Lifting eyes for 3 sections

—

20

Do not pass ropes or cables through lift holes,

use slings with safety hooks or shackles

A

or more

Warning: Cubicles may easily tip over, when

transported with a pallet jack, therefore the

distance between pallet and ground should

not be more than 3mm.

—

21

max 3mm

Loading...

Loading...