Installation

42/68-165-EN RHD250 ... 4000 17

M00347

X

F

R

Fig. 5: Stub shaft

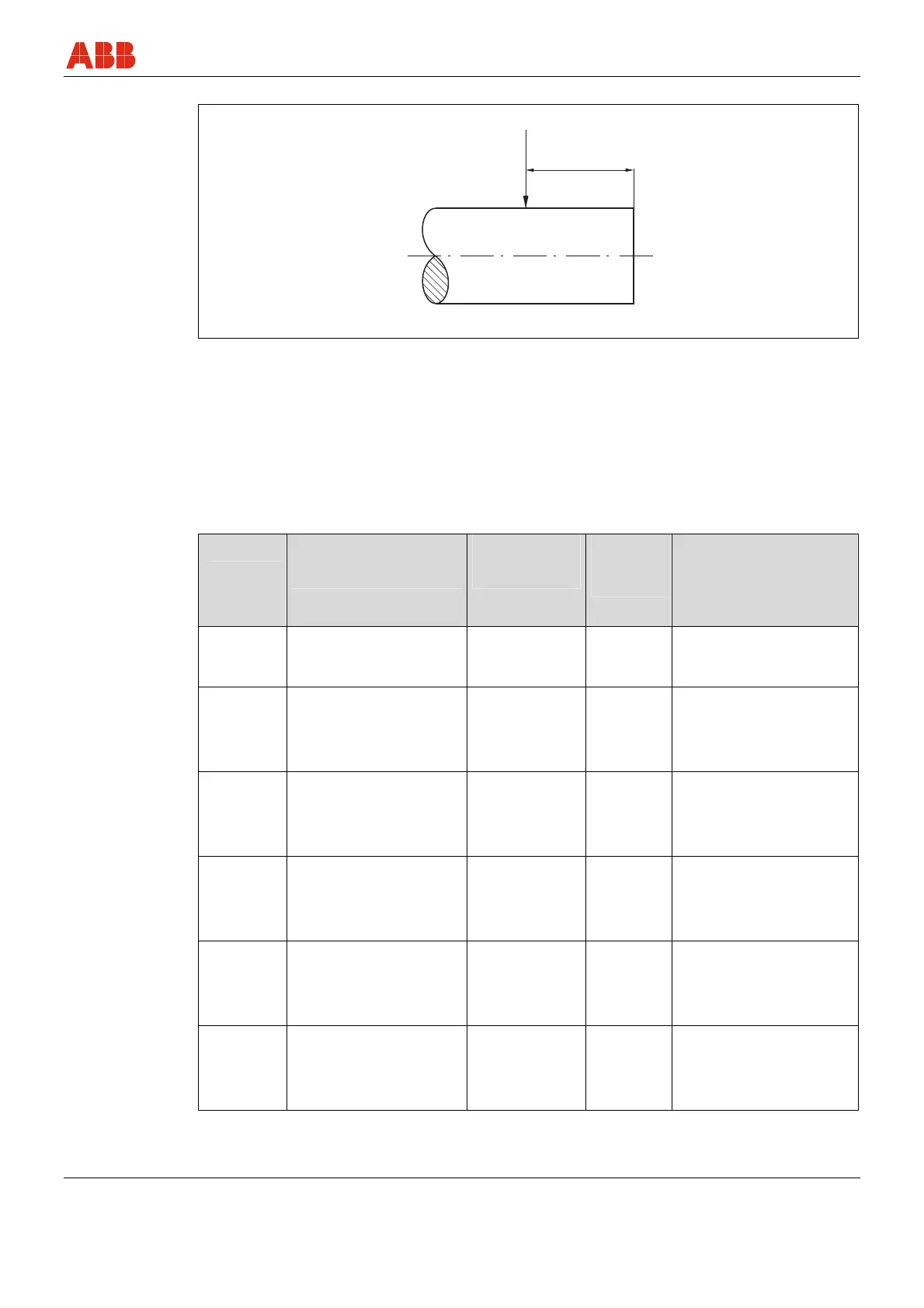

Configuring the drive element hub

The new drive element is mechanically connected to the drive shaft via a hole with feather key

groove . This connection must be constructed so that the rated torque and any possible output

torque is transmitted accurately. The drive element must be mounted securely on the drive shaft

with suitable measures to prevent axial shift. For the new drive element, you can use the current

mechanical stops.

The following parameters must be observed:

Type bore diameter

mm (inch)

Key width

mm (inch)

Hub

length

mm (inch)

Minimum yield strength

of hub Rp 0.2

N/mm

2

(pounds/square

inch)

RHD250

30 +0,033

(1.18 +0.0013)

8 -0,015/-0,051

(0.31 -0.0006/-

0.0020)

50 (1.97) 320 (46412.80)

RHD500

50 +0,039

(1.97 +0.0015)

14-0,018/-

0,061

(0.55 -0,0007/-

0.0024)

70 (2.76) 320 (46412.80)

RHD800

50 +0,039

(1.97 +0.0015)

14-0,018/-

0,061

(0.55 -0,0007/-

0.0024)

70 (2.76) 320 (46412.80)

RHD1250

70 +0,075/+0,030

(2.76 +0,0030/+0,0012)

20-0,022/-

0,074

(0.79 -0.0311/-

0.0029)

100 (3.94) 320 (46412.80)

RHD2500

70 +0,075/+0,030

(2.76 +0,0030/+0,0012)

20-0,022/-

0,074

(0.79 -0.0311/-

0.0029)

100 (3.94) 320 (46412.80)

RHD4000

85 +0,090/+0,036

(3.35 +0.0035/+0.0014)

25-0,018/-

0,061

(0.98 -0,0007/-

0.0024)

140 (5.51) 320 (46412.80)

Pos: 8.25 /====== = Seitenumbruch ======= = @ 0\mod_1126532365768_3101.doc @ 3830

Loading...

Loading...