TZIDC, TZIDC-110, TZIDC-120 DIGITAL POSITIONER | CI/TZIDC/110/120-EN REV. E 41

Change from two to one column

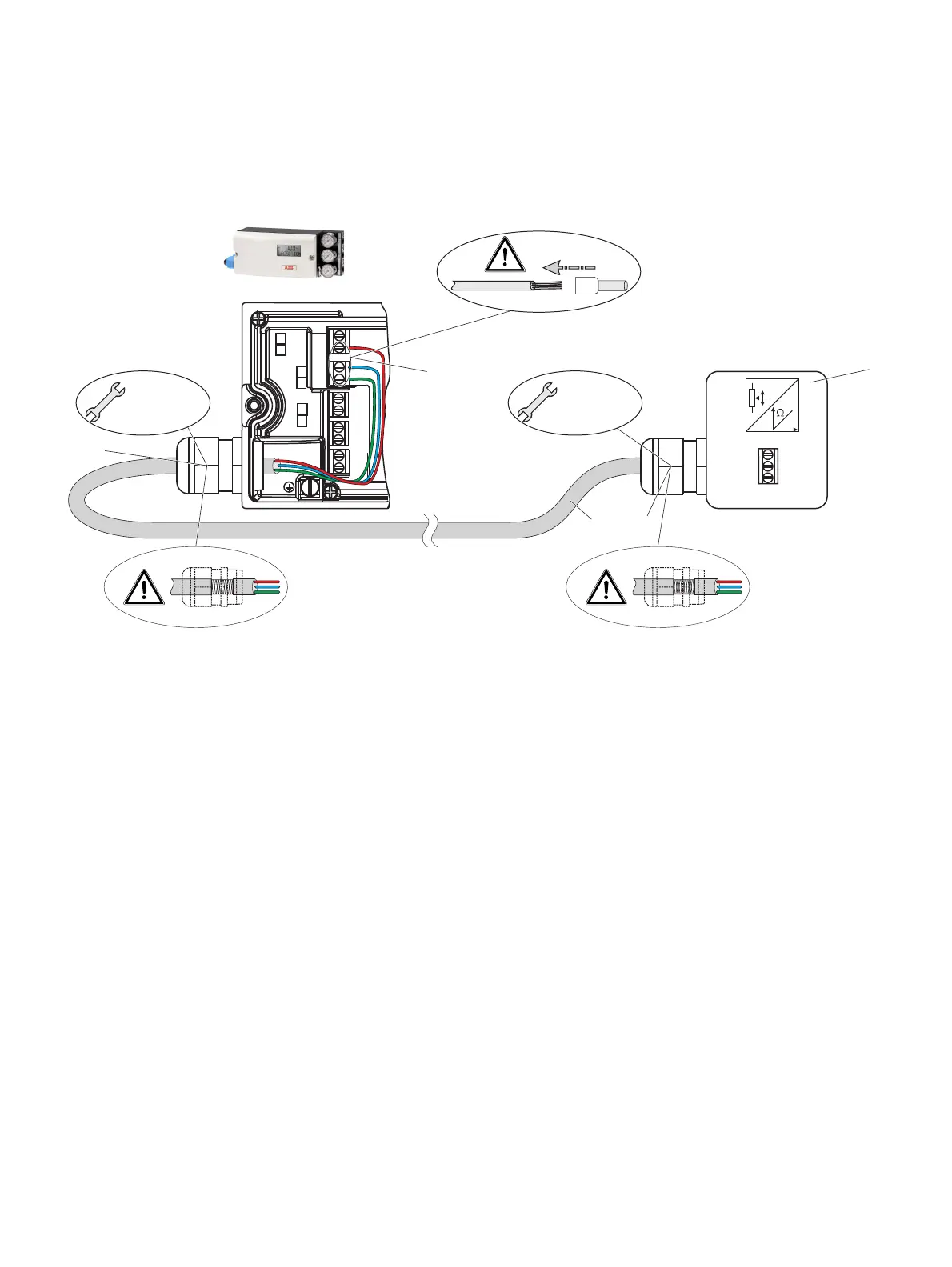

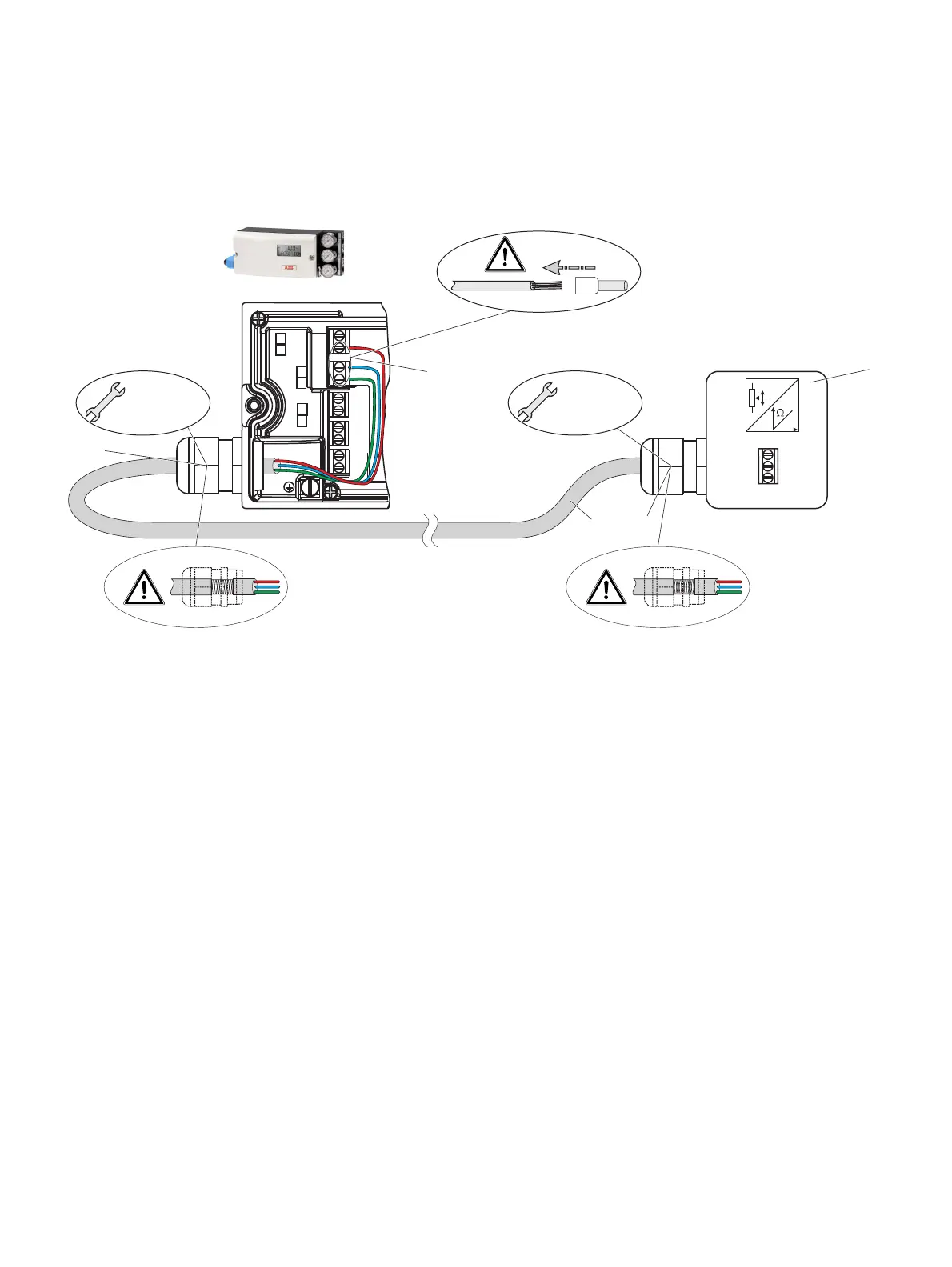

Connection on device - TZIDC Control Unit for remote position sensor

M10903

+31 -32

3

+51 -52

1 2

+11 -12

+83 -84

+81 - 82

+41 -42

1 2 3

1

4 3

3

2

M 20 mm /

1/2"NPT

M 20 mm /

1/2"NPT

1 Terminals for remote position sensor

2 Remote position sensor

3 EMC Cable gland

4 Shielded connection cable

Figure 22: Connection of TZIDC Control Unit with remote position sensor (example)

Change from one to tw o columns

With the TZIDC designed for remote position sensors, the

positioner is supplied without a position sensor.

The housing (TZIDC Control Unit) contains the electronics and

pneumatics along with the following options, where applicable:

• Analog position feedback

• Digital position feedback

Any position sensor (4 to 30 kΩ, with line break detection

4 to 18 kΩ) can be connected.

Connect the positioner (TZIDC Control Unit) and remote position

sensor while observing the following instructions:

• A shielded 3-wire cable with a maximum length of 10 m (33 ft)

must be used for the connection.

• Route the cable into the terminal compartment through the

EMC cable glands. Ensure that the shielding is secured

correctly in the EMC cable glands.

• Connect the cables in accordance with the electrical

connections and tighten the screws of the terminals so that

they are hand-tight.

• The electrical connection of the TZIDC Control Unit and the

optional modules are described in TZIDC / TZIDC Control

Unit terminal assignment on page 33.

• If the TZIDC Control Unit is fastened such that it is it non-

conductive, the housing must be grounded (TZIDC Control

Unit and remote position sensor housing with the same

electric potential); otherwise control deviations could occur

with regard to analog position feedback.

• Use wire end ferrules when connecting.

• The pneumatic outputs must be connected to the actuator

using cables of at least Ø 6 mm (0.23 in).

• If the device is being operated on a cylinder, for reasons

associated with linearity you should run automatic

adjustment for rotary actuators.

Loading...

Loading...