11

Blade Information

Scroll blades wear out and must be replaced frequently for best cutting results. Scroll saw blades

generally become dull after one half hour to 2 hours of cutting, depending on the type of material

and speed of operation.

When cutting wood, best results are achieved when cutting pieces less than one inch (25mm) thick.

When cutting wood thicker than one inch (25mm), the user must guide the workpiece very slowly

into the blade and take extra care not to bend or twist the blade while cutting.

When choosing a blade, carefully consider the following:

Very fine, narrow blades should be used to scroll cut thin material one fourth of an inch (6mm)

thin or less.

Most blade packages state the size or thickness and type of material which the blade is intended

to cut. The package should also state the radius or size of curve that can be cut with that blade.

Wider blades cannot cut curves as tight or small as thinner blades.

Main causes of blade wear:

• Cutting plywood, hardwood and other laminates.

• Cutting material thicker than three fourths of an inch (19mm).

• Side pressure on the blade.

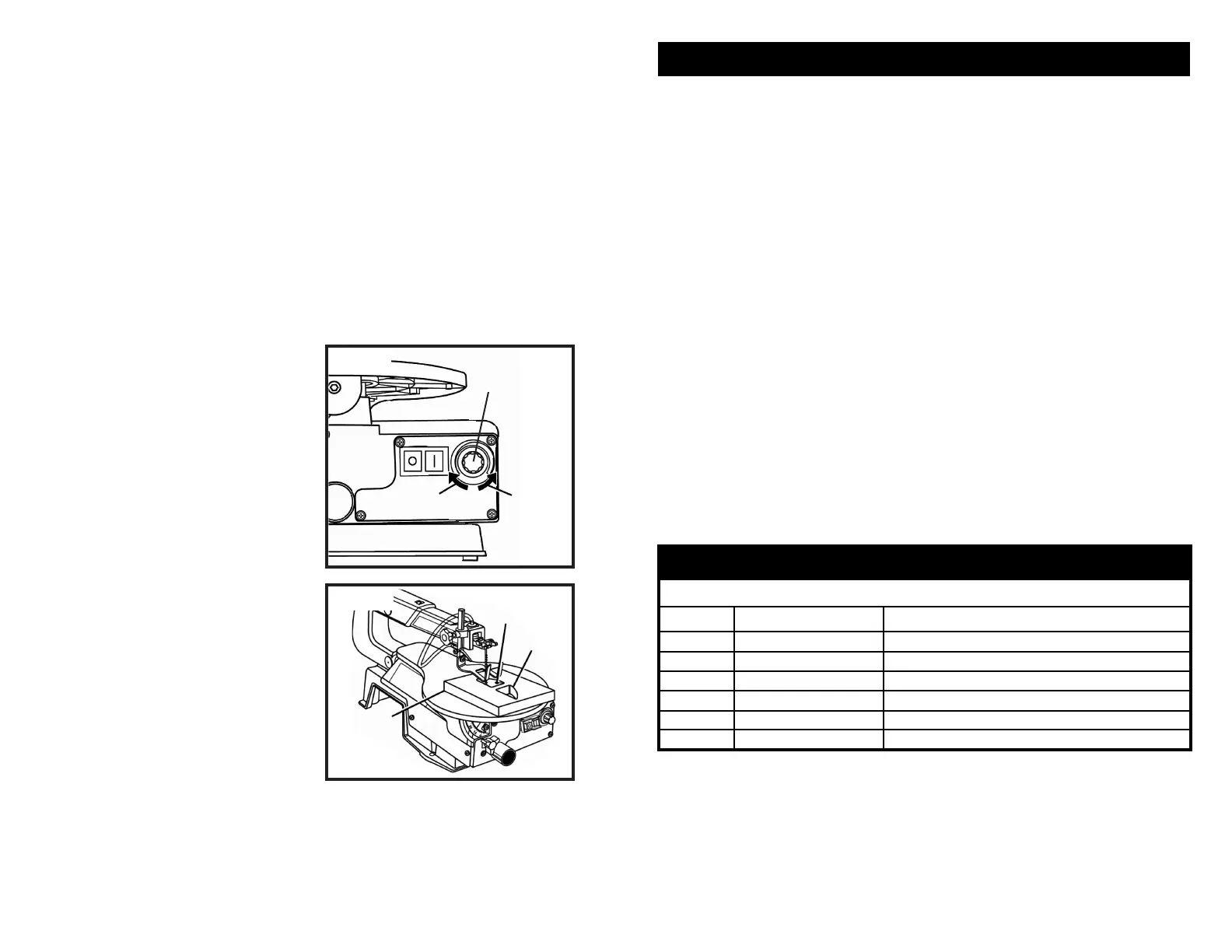

Speed Setting (Figure 12)

By turning the speed selector (1), the saw's

speed may be adjusted from 400 to 1,600 SPM

(Strokes per Minute). To increase the strokes per

minute, turn the speed selector clockwise (3). To

decrease the strokes per minute, turn the speed

selector counterclockwise (2).

Scroll Cutting

Scroll cutting consists of following the pattern

lines by pushing and turning the workpiece at the

same time. Once you have started a cut, do not

try to turn the workpiece without also pushing it;

the workpiece could bind or twist the blade,

causing it to break.

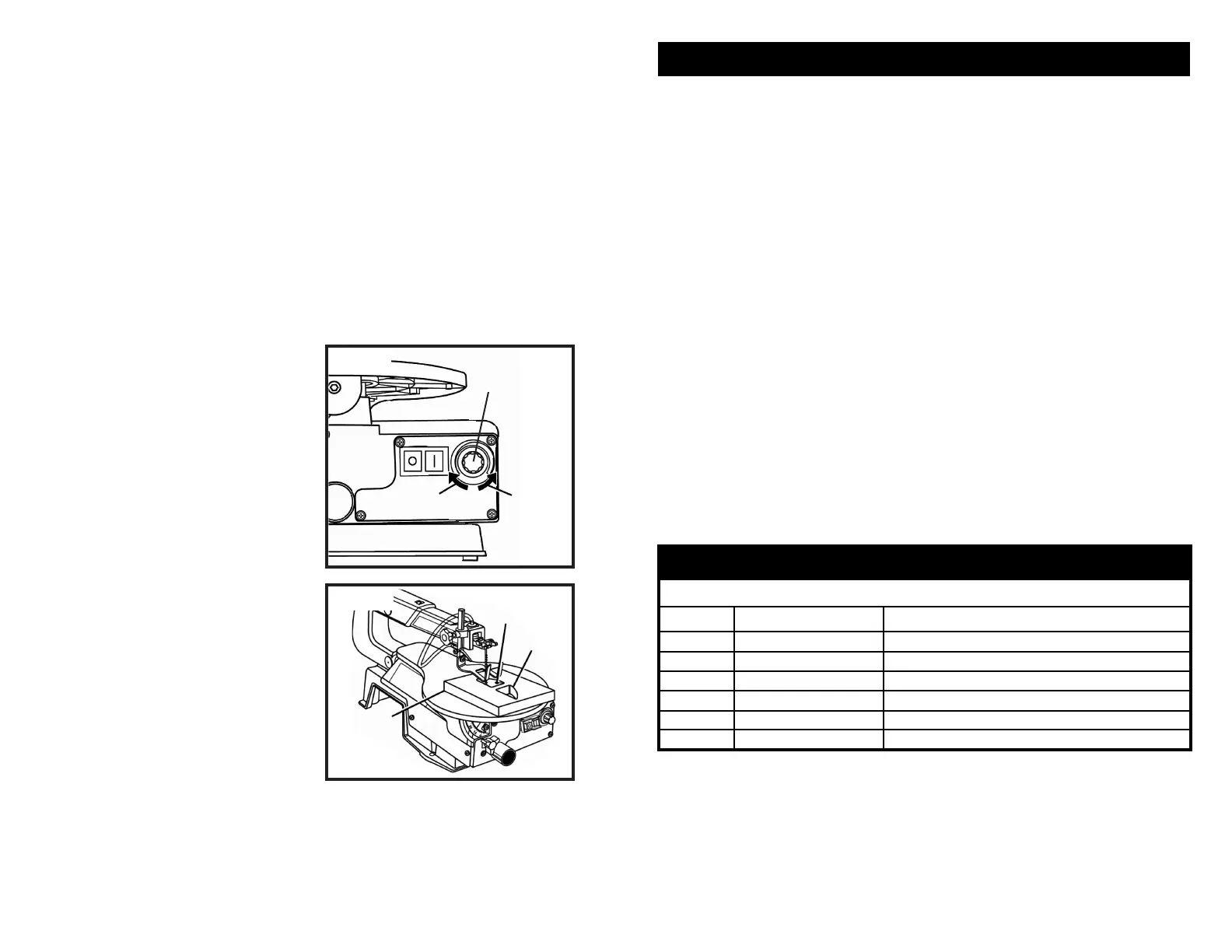

Interior Scroll Cutting (Figure 13)

One feature of the scroll saw is that it can be

used to make scroll cuts within a workpiece

without cutting through the edge or perimeter of

the workpiece.

To make interior cuts in the workpiece:

1. Remove the scroll saw blade as explained in

the section Installing Blades.

2. Drill a hole (1) one fourth of an inch (6 mm) in

size in the workpiece (3).

3. Place the workpiece on the saw table with

the drilled hole over the hole in the table.

4. Install the blade, feeding it though the hole in

the workpiece.

5. Adjust the drop foot and blade tension.

6. When finished making the interior scroll cut (2), simply remove the blade from the blade

holders as described in the section on Installing Blades.

7. Remove the workpiece.

1

2

3

Figure 13

3

1

2

Figure 12

4

The following symbols are used for this tool:

SYMBOLS

V Volts Voltage

Amp Amperes Current

SPM Strokes per minute Speed

~ Alternating Current Type of current

HZ Hertz Frequency (cycles per second)

Min Minutes Speed

Symbol Name Designation/Explanation

GLOSSARY OF TERMS

Bevel Cut - A cut made with the saw table at any angle to the blade other then 90 degrees.

Crosscut - Any cut made across the width or grain of the workpiece.

Freehand - Any cut made when the workpiece is not guided by a fence or mitre gauge.

Gum - A sap or sticky substance in wood products.

Kerf - The slot that is produced by the blade in a partial cut (a non-through cut) or the material

removed from the workpiece by the blade.

Kick back - A sudden movement of the workpiece, typically in the opposite direction of the cut.

Leading end - The end of the workpiece that is pushed into the blade first.

Non-ferrous Metal or Alloy - A metal or ally that does not contain iron (such as aluminum, copper

or brass)

Push Stick - A device which is used to push the workpiece through the saw. Typically used when

cutting very narrow workpiece.

Resin - A sticky, sap based substance that has hardened.

Ripping - A cut made along the length of the workpiece.

Saw Blade Path - The area on the workpiece that is directly in line with the blade.

SPM - Storks per minute. The number of times the blade travels up (or down) in a minute

of operation.

Through Cut - A cutting operation in which the blade completely cuts through a workpiece.

Workpiece - The item being cut by the saw.

Worktable (Saw Table) - The surface on which the workpiece rests during the cutting operation.

Loading...

Loading...