深圳利洋焊接设备 Shenzhen LiYang welding Equipment Co., Ltd

LY

as possible .Avoid it closing to air conditioners, fans and the other outlet.

2、 IR6000 Rework Station sensor Direct contact with motherboard,So Temperature

display is Actual temperature。

3、 In order to avoid damage to the motherboard capacitor,SO use insulation tape please ,

Maintenance completed ,then Removal of insulation tape ,So as to avoid short-circuit!

4、 After removal of BGA chip ,PCB Bonding Pad Need to clean up ,Avoid cold solder joint

See BGA chip tin completely liquefied, Then To move the BGA chip,So as to avoid Bonding

Pad Damage !

5、

BGA chips should be subject to settlement, floating state Prohibited in all solder ball

did not fully liquefied, by force if removal of chips, so as to avoid pad off, chip or

motherboard scrap!

6、 To improve success rate of Rework , PCB and chips need drying and processing in principle,

PCB board or chip moist heat process will occur in the burst phenomenon, the Rework

process may hear the blasting sound of a minor。According to actual situation Please,

self-control.

7、 PCB board heating time is too long or repeated several times the surface heating will lead to

discoloration.

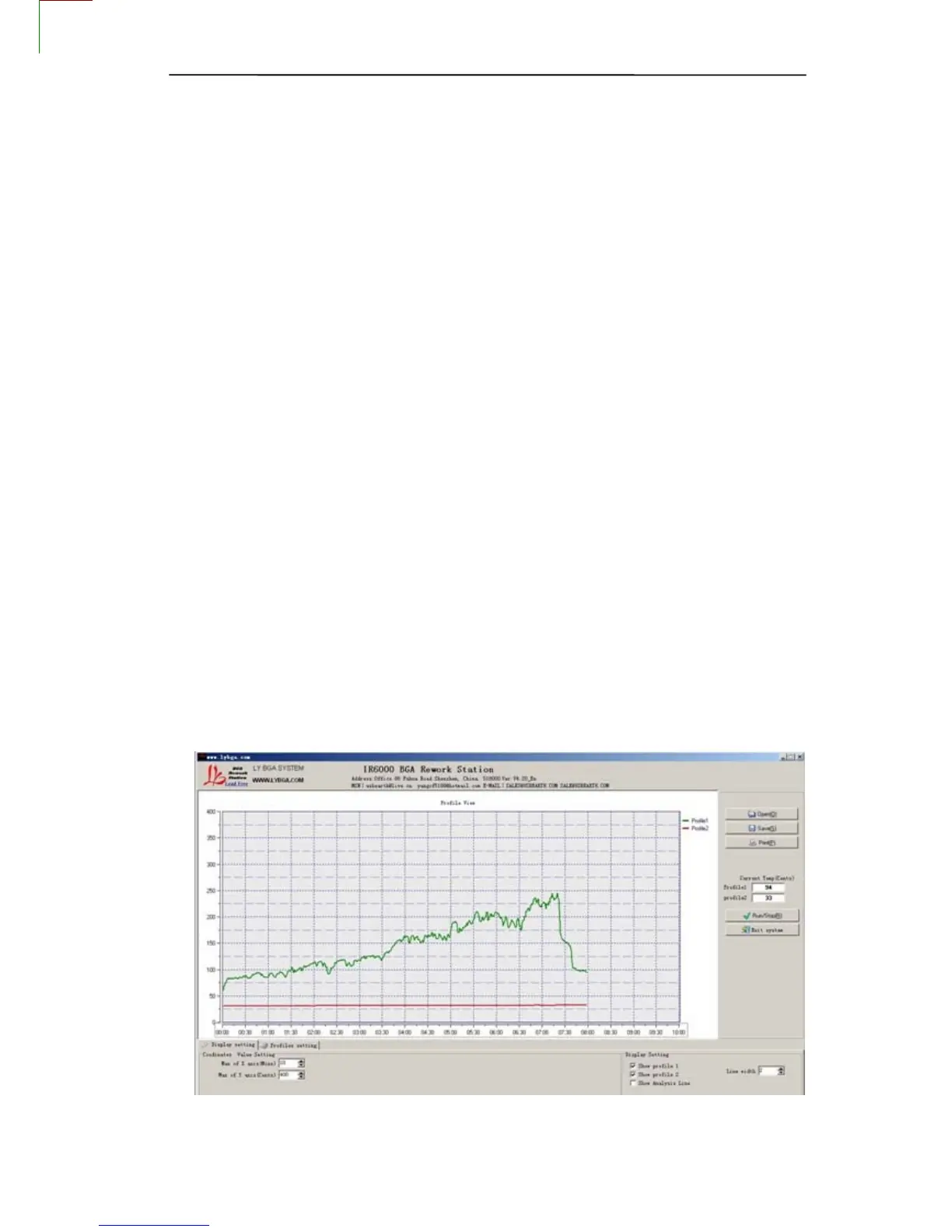

8、 Users from modifying temperature parameters,Please use scrap PCB tested,Heating whole

time about 10 seconds before the end of solder balls should be fully liquefied,f the

liquefaction advanced or delayed,,!Should be regulating up/down the temperature setting.

So as to avoid heat damage to chips or low-temperature sealing-off。

9、 The factory equipped with two sets of programmable temperature control table used

parameters:

The attached curve setting for reference

WWW.LYBGA.COM

16

Loading...

Loading...