22 American Dryer Corp. 113403-17

Piping / Connections

CE and Australian dryer connections will be B.S.P.T., all others will be N.P.T.

There should be a minimum 6-inch (15.24 cm) clearance

between the back guard and the first bend in the gas piping

for ease of servicing. It is recommended that a gas shutoff

valve be provided to the gas supply line of each dryer for

ease in servicing.

The size of the main gas supply line (header) will vary

depending on the distance this line travels from the gas

meter or, in the case of L.P. gas, the supply tank, other gas-

operated appliances on the same line, etc. Specific

information regarding supply line size should be determined

by the gas supplier.

NOTE: Undersized gas supply piping can create a low or

inconsistent pressure, which will result in erratic operation

of the burner ignition system.

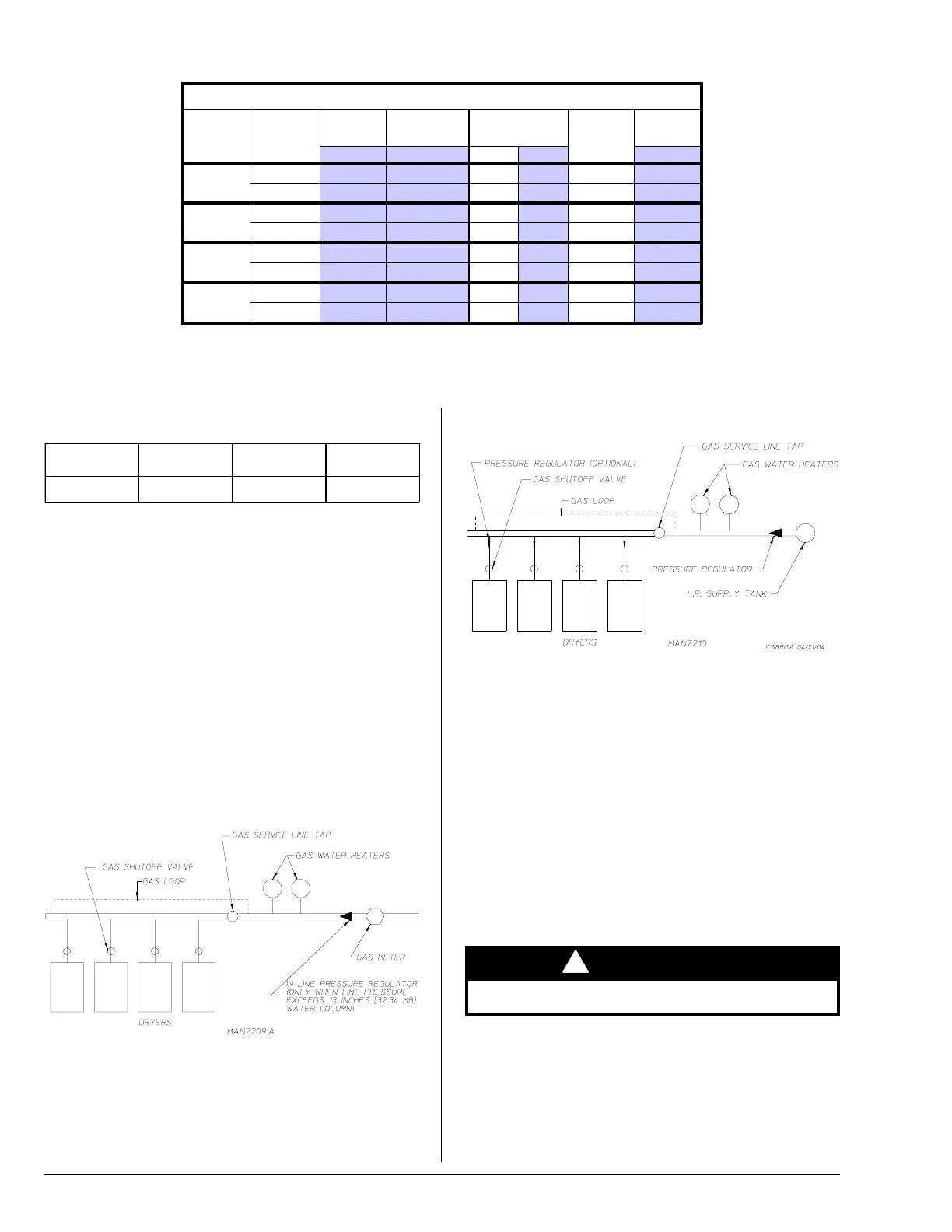

TYPICAL NATURAL GAS INSTALLATION

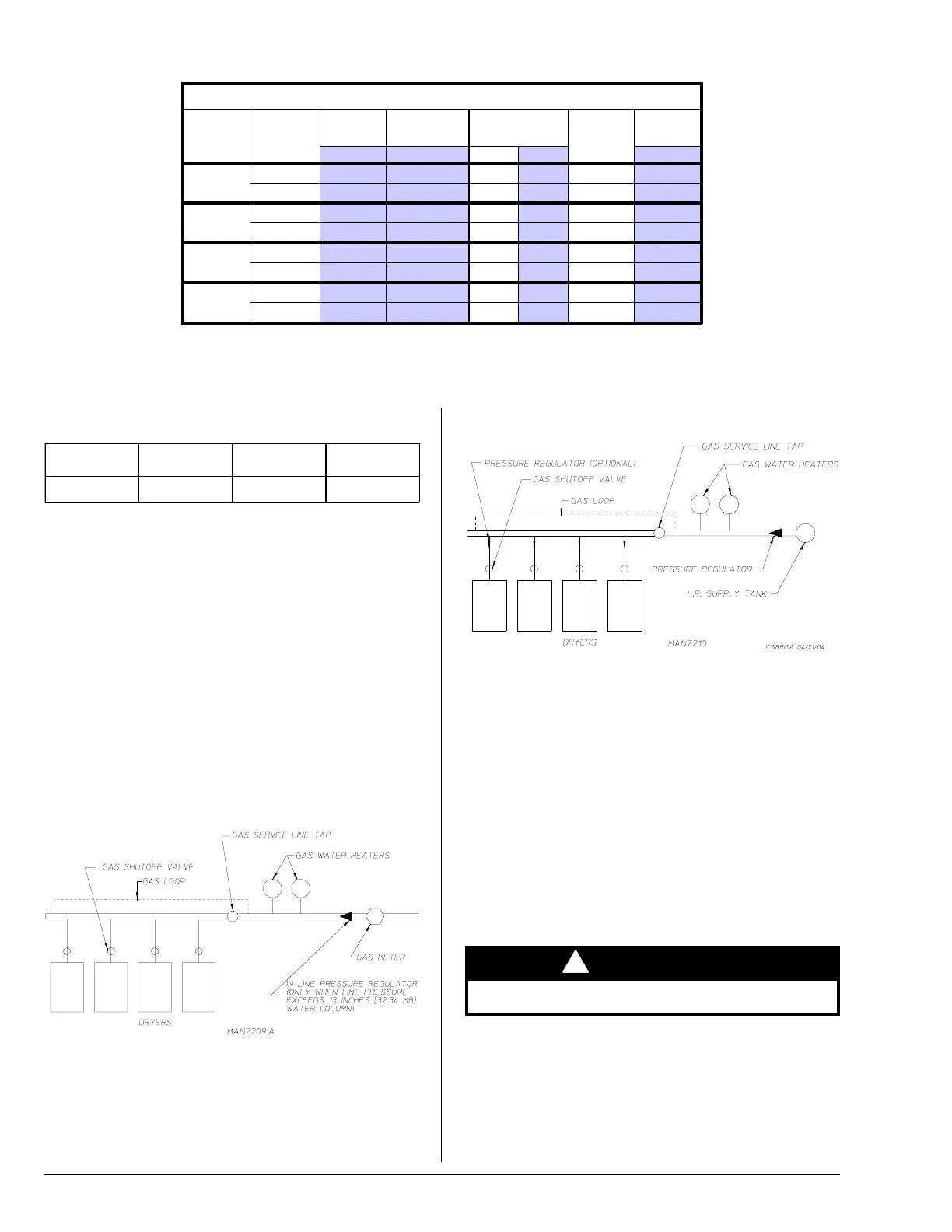

Consistent gas pressure is essential at all gas connections.

It is recommended that a 3/4-inch (19.05 mm) pipe gas

loop be installed in the supply line servicing a bank of dryers.

An in-line pressure regulator must be installed in the gas

supply line (header) if the (natural) gas pressure exceeds

13.0 in WC (32.34 mb) pressure.

A plugged tap, accessible for a pressure gauge connection,

must be installed in the main gas supply line immediately

upstream of the dryers.

IMPORTANT: Pipe joint compounds that resist the action

of natural, L.P., and butane gases must be used.

Test all connections for leaks by brushing on a soapy

water solution (liquid detergent works well).

!

WARNING

Never test for leaks with a flame!!!

SL20 SL31 SL50 SL75

3/8” 1/2” 1/2” 1/2”

TYPICAL L.P. GAS INSTALLATION

Heat Input / Gas Consumption / Orifice (Injector) Data (For AGA [Australian] Models Only)*

Gas Specifications for AGA Approved Dryers (Australia)

Model

Gas

Type

Supply

Pressure

Gross

Heat Input

Orifice Size

Orifice

(Injector)

Quantity

Burner

Pressure

kPa MJ/h DMS mm kPa

SL20

Natural

1.7-3.2 42.20

30

3.264

1

0.67

Propane

2.75 42.20

49

1.854

1

2.30

SL31

Natural

1.7-3.2 58.03

22

3.988

1

0.69

Propane

2.75 58.03

44

2.184

1

2.49

SL50

Natural

1.7-3.2 94.96

29

3.454

2

0.72

Propane

2.75 94.96

47

1.994

2

2.49

SL75

Natural

1.7-3.2 116.06

22

3.988

2

0.69

Propane

2.75 116.06

44

2.184

2

2.49

Shaded areas are stated in metric equivalents

* Consult factory for elevations over 2,000 feet (610 meters) for correct orifice size.

Loading...

Loading...