The “weep” holes are not condensate drains, and need

not be trapped. They may be plugged or left open for

automatic drainage.

SERVICE CONTINUED

PROCEDURE FOR COMPRESSOR REPLACEMENT

Isolate the compressor and remove the refrigerant from

system.

Remove the inoperative compressor.

Install a properly sized suction line filter-drier in the

compressor suction line and replace liquid line drier.

Examine expansion valves and solenoid valves to see if

cleaning or replacement is required.

Install the replacement compressor.

Evacuate the compressor and system to 500 microns.

Open the compressor service valves and charge the

system with R410A after compressor evacuation.

Operate the system. Check the pressure drop across the

suction and liquid drier after the first 1½ hours of

operation. Pressure drop across a liquid line drier should

not exceed 5 PSI and the suction line filter-drier should

not exceed 3 PSI.

After 8 to 24 hours, take an oil sample and test with an

acid test kit. If the oil dirty or acidic, change the suction

line and liquid line filter drier and recheck after 8 hours of

compressor operation.

After two weeks, recheck oil acidity to see if another

change of suction line and liquid line filter-drier is

necessary.

In some cases non-condensable gases are produced

during the burnout. Compare the equalized head

pressure with the pressure (equivalent) to the outdoor

temperature. If the pressures are different, then the

system should be purged.

System cleaning after compressor mechanical failures:

Mechanical compressor failures such as oil pump, valve

plates, etc. may not necessarily contaminate the system.

Check oil of defective compressor by means of an oil

acid kit and check compressor for shorts, grounds and

continuity- if all checks negative, then it is only

necessary to evacuate replacement or repaired

compressor and install a new liquid line drier. Make an

acid test after 8 hours of operation.

ORDERING PARTS

When reporting shortages or damaged parts, give the

complete unit model and serial number which is stamped

on the unit rating plate. These units are made special to

order and the following parts list should only be used as

a guide. Do not order parts from these lists.

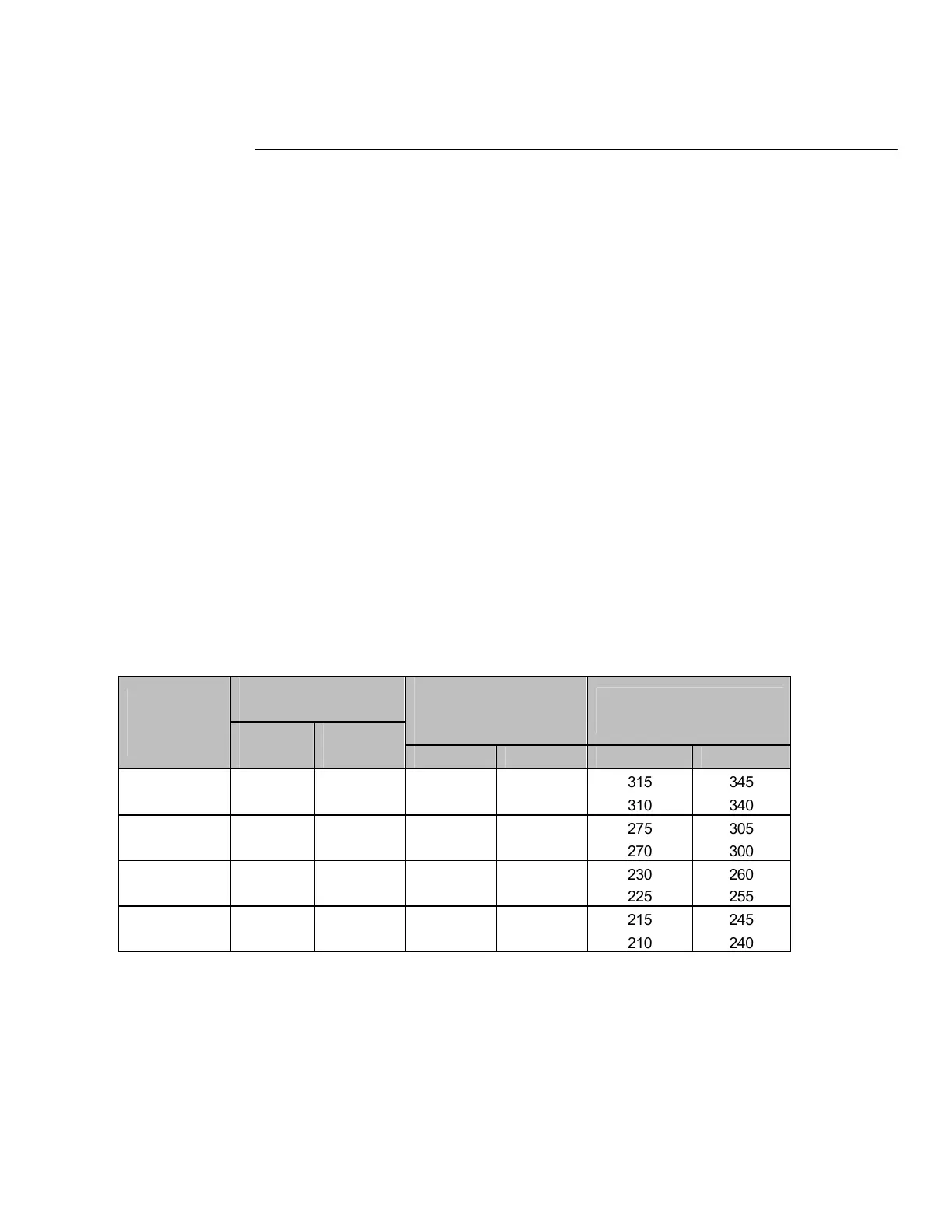

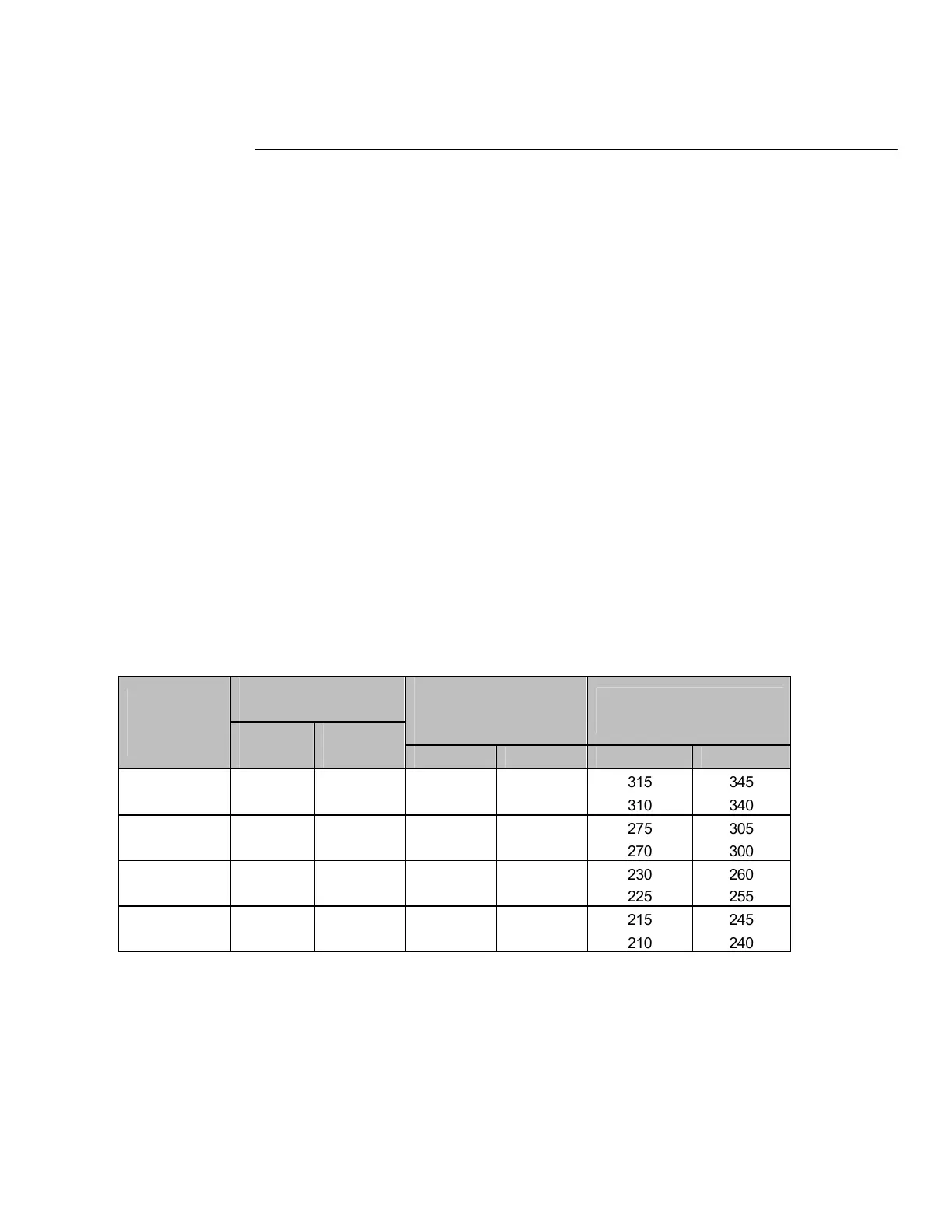

Cooling Performance Data at 200 CFM Per Ton

Evaporator Inlet Air

°F

Evaporator Inlet-

Outlet Air Temp

Differential, DB°F

High Side Pressure

psig

Condenser

Inlet Air

Dry Bulb°F

Dry

Bulb

Wet

Bulb Min. Max. Min. Max.

105 105

87

82

58

33

33

38

315

310

345

340

95 95

80

75

37

32

32

37

275

270

305

300

85 85

72

67

26

31

31

36

230

225

260

255

75 75

65*

60*

22

26

27

31

215

210

245

240

*Condenser fan at part load RPM, unit at partload operation

Loading...

Loading...