INSTALLATION CONTINUED

Once it is established that supply voltage is within the

utilization range; check and calculate if an unbalanced

condition exists between phases. Calculate percent

voltage unbalance as follows:

Percent Maximum Voltage Deviation

Voltage = 100x From Average Voltage

Unbalance Average Voltage

FOR EXAMPLE - With voltage of 220, 215, and 210

(Measure L1-L2, L1-L3, L2-L3).

Average voltage = 645 ÷ 3 = 215

Maximum voltage deviation from

Average voltage = 220 - 215 = 5

Percent 100 x 5 = 500

Voltage Unbalance

215 215 = 2.3%

Percent voltage unbalance must not exceed (2%)

two percent.

Contact power company if phase unbalance exceeds

2%.

A means of disconnecting power from the unit must be

placed adjacent to the unit in accordance with National

Electrical Code or local codes. Aluminum power wire is

not recommended.

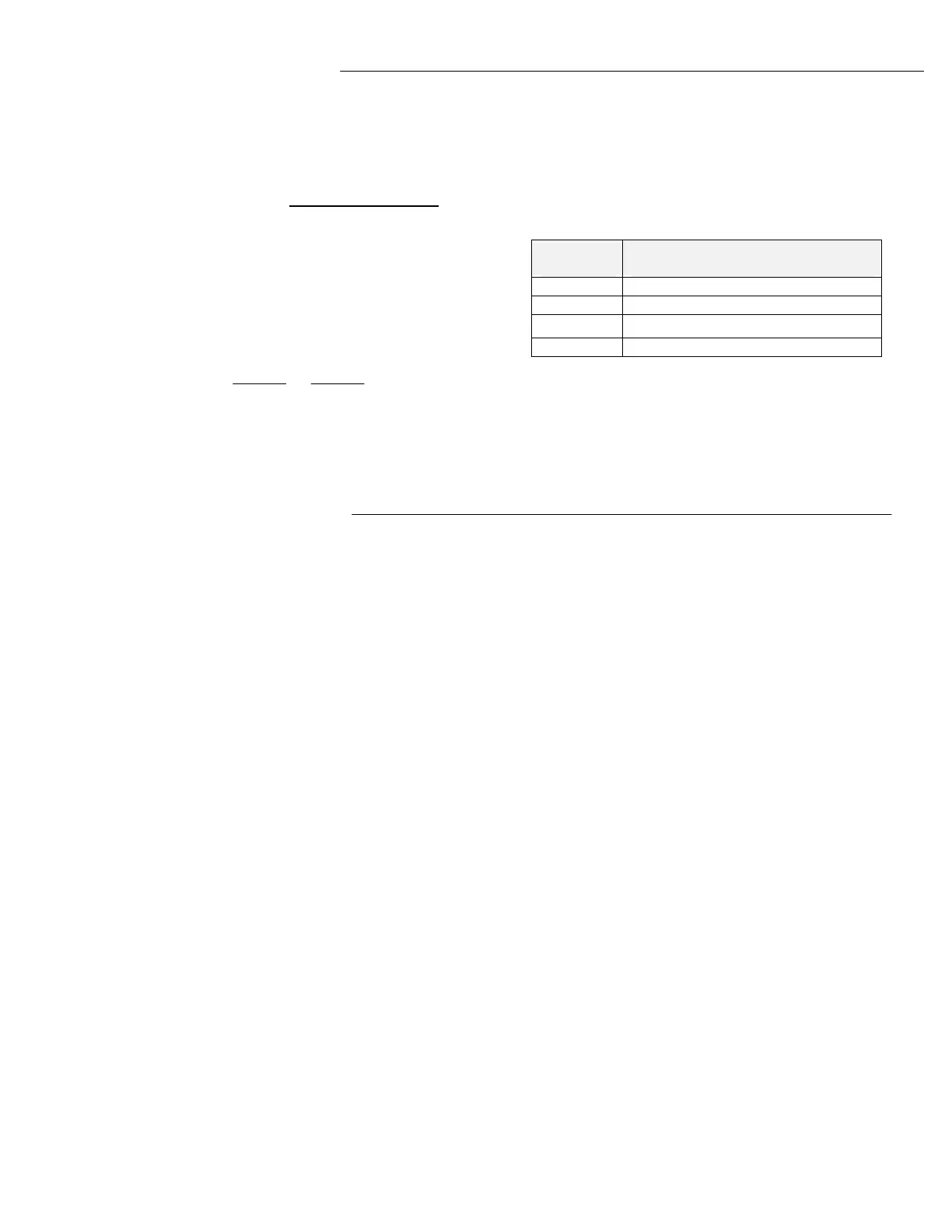

LOW VOLTAGE CONTROL WIRING

Control System Wiring: For commercial equipment the

following table lists the minimum size of 24 volt class 2

wire to be used.

Ft. Run From Unit to

Wire Size System Switch or Longest Run

18 A W G Maximum Run 50 Feet

16 A W G Maximum Run 75 Feet

14 A W G Maximum Run 100/125 Feet

12 A W G Maximum Run 150/200 Feet

Note: Wiring – Consult the wiring diagram furnished with

the unit. These units are custom designed for each

application.

The wiring diagrams in this publication are furnished only

as a guide to the installing contractor. The unit wiring

diagram is located inside the control panel of each unit.

SEQUENCES OF OPERATION

Temperature Controls: The Ambient Compressor

Thermostat controls compressor on/off operation. The

use of space or duct mounted sensors to control the

compressor will produce unpredictable results. On

systems with optional Hot Gas Reheat a discharge air

thermostat is mounted in the air handler. A

temperature/humidity sensor located in the conditioned

space may be used in conjunction with the control for

Hot Gas Reheat. A remote system switch such as a time

clock or interlock may be used to energized the controls.

Mechanical Cooling

The evaporator blower starts when the system switch is

closed. When the outdoor temperature rises above the

set point of the adjustable outdoor thermostat, the

compressor is active until the thermostat is satisfied. The

leaving air temperature will be maintained by hot gas

bypass and/or unloading the compressor. This is

accomplished through suction-pressure sensing, thus

tracking the outside air temperature variations.

When the outdoor temperature falls below the set point

of the adjustable outdoor thermostat (normally 56°F), the

compressor is deactivated.

Condenser Head Pressure Control

VARISPEED fan motor and control is standard with

all reheat options because units operating in low ambient

temperature require a control system to maintain stable

head pressure. Head pressure control is accomplished

with one or two variable speed condenser fan drives. A

pressure sensing control modulates the condenser fan

speed as required to maintain head pressure between

320 psig and 430 psig.

The Varispeed fan motor has been designed and tested

to withstand the high temperatures incurred during

variable speed operation DO NOT SUBSTITUTE.

Single fan models are equipped with one variable speed

motor and control.

Dual fan models may be are equipped with one single

phase variable speed motor and one 3 phase motor.

Four fan models may be equipped with one variable

speed motor and three 3 phase motors.

This pressure sensing system consists of a variable

speed motor driven fan and a constant speed motor

driven fan. Both are controlled from refrigerant pressure

rather than ambient temperature, reflecting actual

operating conditions in the machine.

At low ambient, the variable speed fan operates,

increasing in speed until maximum RPM is achieved at

or around 45°F (±2) ambient. An adjustable pressure

switch operates the constant speed three-phase fan set

to energize the motor at 400 psig and de-energize at 295

psig. In the ambient temperature span of approximately

50°F to 53°F, the variable speed fan will ramp between

maximum and minimum speed while the constant speed

fan cycles. The start-stop cycle varies from 45 seconds

to 22 minutes during this period.

At 53°F (±2), both fans are operating, the variable speed at

minimum RPM and the constant speed at full RPM. As the

ambient continues to rise, the variable speed motor increases

to full speed and remains there.

Loading...

Loading...