INSTALLATION Continued

UNIT INSTALLATION

Lower unit carefully onto roof mounting curb or mounting

rails or ground level slab. While rigging unit, center of

gravity will cause condenser end to be lower than

supply/return air end. Bring condenser end of unit into

alignment with curb. With condenser end of unit resting

on curb member and using curb as fulcrum, lower front

end of unit until entire unit is seated on curb.

Rigging Removal

Remove spreader bars, lifting cables and other rigging

equipment.

CAUTION: Do not allow crane hooks and spreader bars

to rest on roof of unit.

Ductwork

Properly sized and installed ductwork is critical to

reliable performance of the unit and system. Unit

connection sizes are in the engineering specification

manual. All ductwork must be installed according to local

codes, practices and requirements.

Industry manuals should be used as a guide to sizing

and designing the duct system.

Ducts passing through unconditioned spaces must be

well insulated with vapor barrier to prevent

condensation.

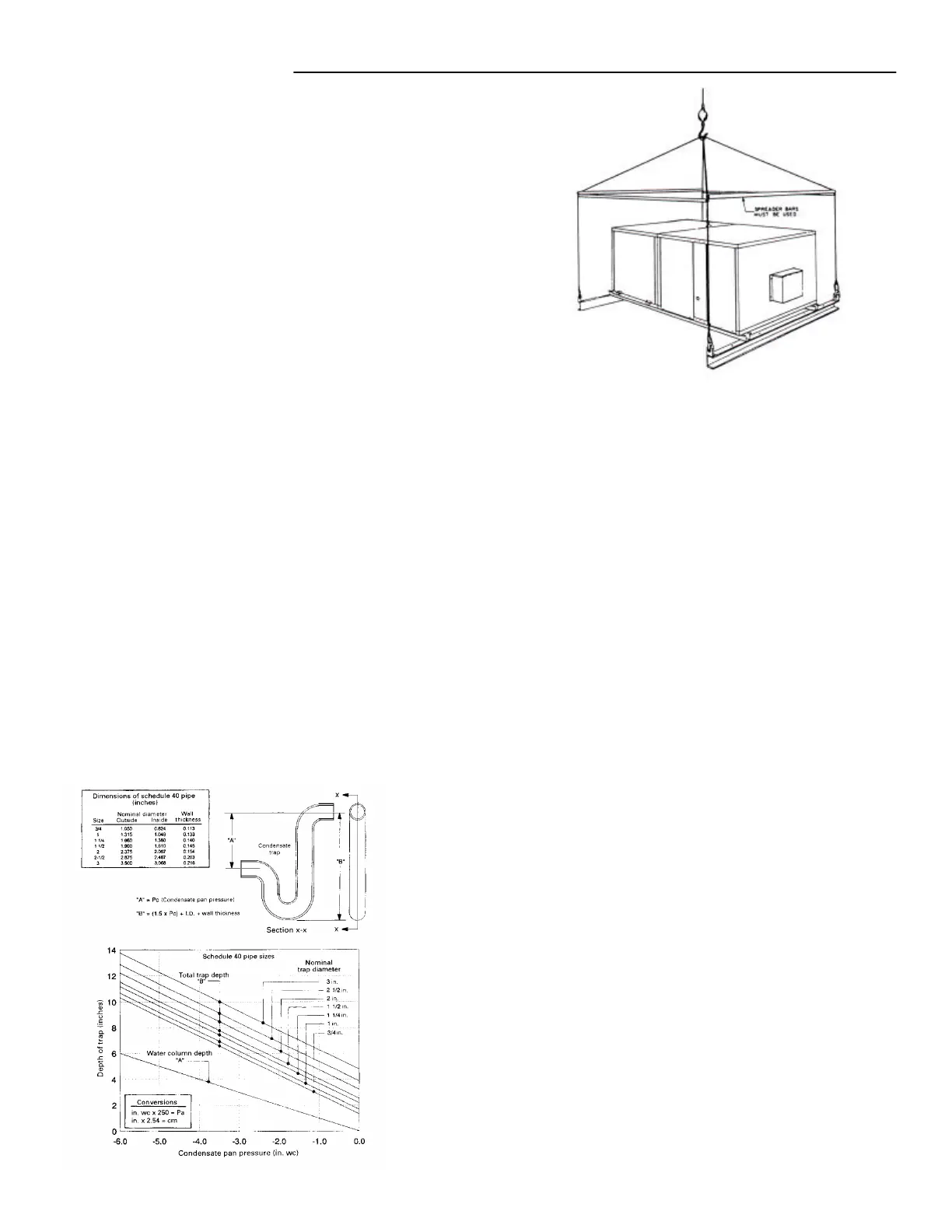

Condensate Piping

A condensate trap must be provided by customer.

Drainage of condensate directly onto the roof is

acceptable if permitted by local codes. It is

recommended that a small drip pad of either stone,

mortar, wood or metal be provided to prevent any

possible damage to the roof. If condensate is to be

piped into the building drainage system, the drain line

must penetrate the roof external to the unit. Refer to

local codes for additional requirements.

Electrical

Wiring Connections

Power wiring should be connected to the main power

terminal block located within the unit main control

section. Power wiring connections on units with factory

disconnects should be made at the line side of the

disconnect switch.

Low voltage wiring connections are made to the remote

mounted controller or time clock.

DO NOT TAMPER WITH FACTORY WIRING

Contact your local representative or the factory if

assistance is required. The internal power and control

wiring of these units is factory installed and each unit is

thoroughly tested prior to shipment.

Independent Power Source

It is recommended that an independent 115 volt power

source be brought to the vicinity of the rooftop unit for

portable lights and tools used by the service mechanic.

Main Power Wiring

The units are factory wired for the voltage shown on the

nameplate.

Main power wiring should be sized for the minimum wire

ampacity shown on the nameplate.

An external weather-tight disconnect switch properly

sized for the unit total load is required for each unit.

Disconnect must be installed in accordance with Local

and/or National Electric Codes.

Power wiring may enter the Rooftop Unit through the

side on all models, or through the unit base and roof

curbs on models with the Power Through Curb option.

Install conduit connectors at the entrance locations.

External connectors must be weatherproof.

Grounding

All units must be properly grounded. The ground lug is

provided for this purpose. DO NOT use the ground lug

for connecting a neutral conductor. The unit must be

electrically grounded in accordance with local codes, or

in the absence of local codes, with the NEC ANSI/NFPA

70 1981.

Loading...

Loading...